Production technique of zinc sulfate monohydrate

A production process, zinc sulfate technology, applied in the direction of zinc sulfate, etc., can solve the problems of cadmium content not meeting the technical requirements, low cadmium content, high zinc content, etc., to improve raw material utilization rate and product output rate, and reduce heat energy consumption , the effect of increasing the content of zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

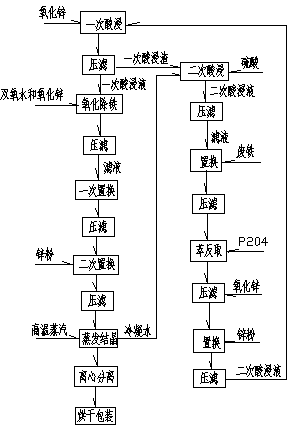

Image

Examples

Embodiment 1

[0025] Embodiment 1, the zinc sulfate monohydrate production process described in present embodiment 1 is:

[0026] (1) React zinc oxide with a weight ratio of 20% and a sulfuric acid solution with a weight ratio of 80% to form a stage of acid leaching, and then press filter to form a stage of acid leaching solution and a stage of acid leaching residue.

[0027] (2) Add hydrogen peroxide accounting for 6% of the weight of one section of acid dipping solution and add zinc oxide accounting for 1% of the weight of one section of acid dipping solution in the section of acid dipping solution formed in step (1), to make iron oxide precipitate and make one section of acid dipping solution Iron removal and neutralization, and then press-filter the neutralized pickling solution,

[0028] (3) Add zinc powder to the one-stage acid leaching solution after pressure filtration in step (2) for two replacements, and replace and purify the cadmium ions in the one-stage acid leaching solution, ...

Embodiment 2

[0034] Embodiment 2, the zinc sulfate monohydrate production process described in present embodiment 2 is:

[0035] (1) React zinc oxide with a weight ratio of 15% and a sulfuric acid solution with a weight ratio of 85% to form a stage of acid leaching, and then press filter to form a stage of acid leaching solution and a stage of acid leaching residue.

[0036] (2) Add hydrogen peroxide accounting for 4% of the weight of one section of acid dipping solution and add zinc oxide accounting for 1.2% of the weight of one section of acid dipping solution in the section of acid dipping solution formed in step (1) to make iron oxide precipitate and make one section of acid dipping solution Iron removal and neutralization, and then press-filter the neutralized pickling solution,

[0037] (3) Add zinc powder to the one-stage acid leaching solution after pressure filtration in step (2) for two replacements, and replace and purify the cadmium ions in the one-stage acid leaching solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com