Negative electrode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of unsatisfactory specific capacity of batteries, high hydrothermal reaction temperature, long reaction time, etc., to reduce irreversible The effect of capacity loss, low synthesis temperature, and fine and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: 0.75 mmol of zinc oxide and 0.25 mmol of vanadium pentoxide were added to 8 mL of deionized water, and magnetically stirred for 30 min. The suspension was transferred to a polytetrafluoroethylene reaction kettle, sealed and heated to 140°C, kept at constant temperature for 24 hours, and then naturally cooled to room temperature. The product was centrifuged from solution and dried in air. The obtained lithium-ion battery negative electrode material powder has a shape of nanosheets, a sheet thickness of about 40 nm, and a sheet size of about 4 μm.

Embodiment 2

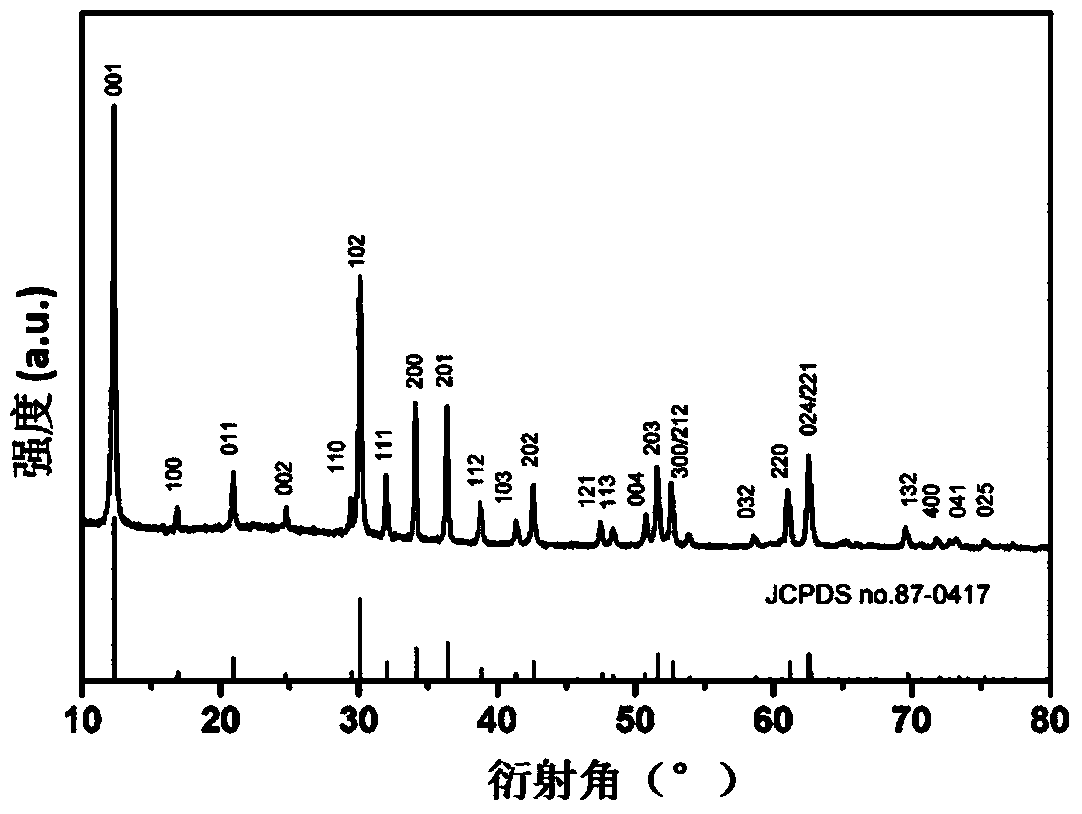

[0028] Example 2: 0.75 mmol of zinc oxide and 0.25 mmol of vanadium pentoxide were added to 8 mL of deionized water, and magnetically stirred for 30 min. The suspension was transferred to a polytetrafluoroethylene reactor, sealed and heated to 60°C, kept at a constant temperature for 24 hours, and then naturally cooled to room temperature. The product was centrifuged from solution and dried in air. The obtained lithium-ion battery negative electrode material powder has a flower-like multi-level structure composed of nano-sheets, and the particle size is about 2.5 μm. The results of its phase analysis are as follows figure 1 , the shape analysis results are as follows figure 2 .

Embodiment 3

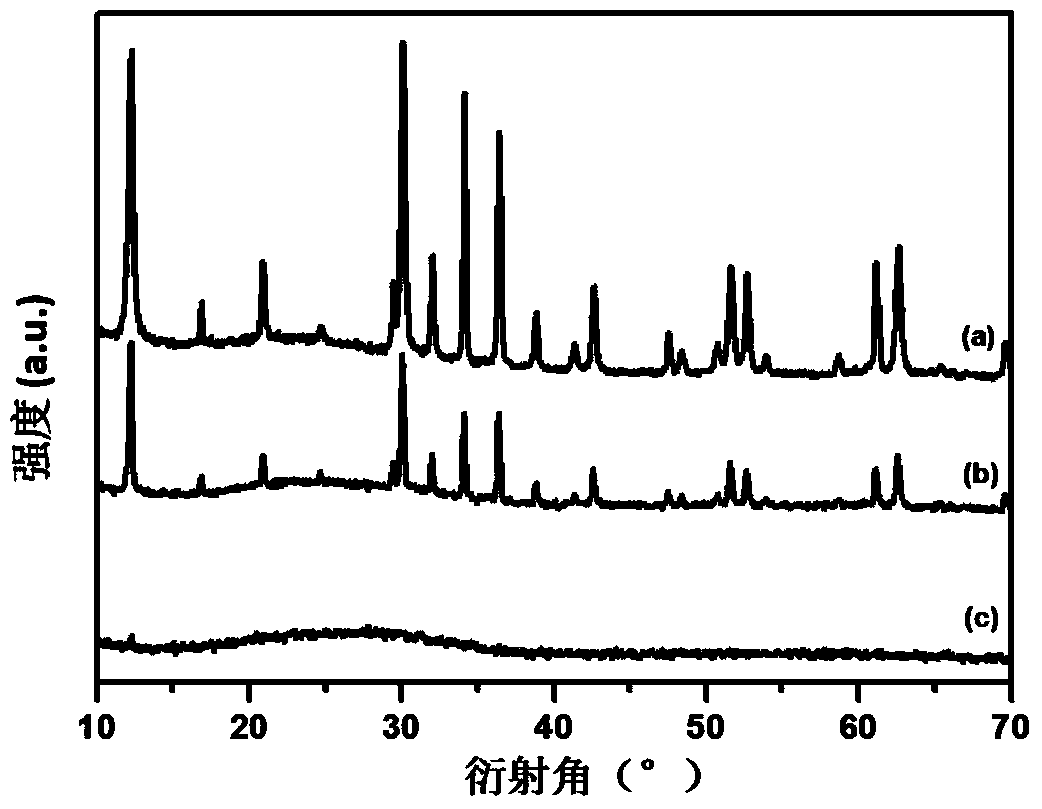

[0029] Embodiment 3: by Zn 2.97 Fe 0.03 V 2 o 7 (OH) 2 (H 2 O) 2 The stoichiometric ratio of the elements in the chemical formula was weighed respectively to zinc nitrate, ammonium metavanadate and ferric nitrate, and added to 12ml of deionized water. The mixture was magnetically stirred at room temperature for 30 min and then transferred to a polytetrafluoroethylene reactor. The reaction temperature was 80° C. and the reaction time was 20 h. The product was centrifuged from solution and air dried. Obtain Fe1.0% lithium ion battery negative electrode material powder, its phase analysis is as follows image 3 Curve a, its shape is the same as that of the sample in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com