Method for preparing rare earth element-doped nickel cobalt lithium manganate positive electrode material

A technology of nickel-cobalt lithium manganese oxide and rare earth elements, which is applied in the field of preparation of nickel-cobalt lithium manganese oxide cathode materials, can solve problems such as lack of cobalt resources, high cost of lithium-ion batteries, and limited expansion of application fields, and achieve excellent cycle performance , low price of raw materials, high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

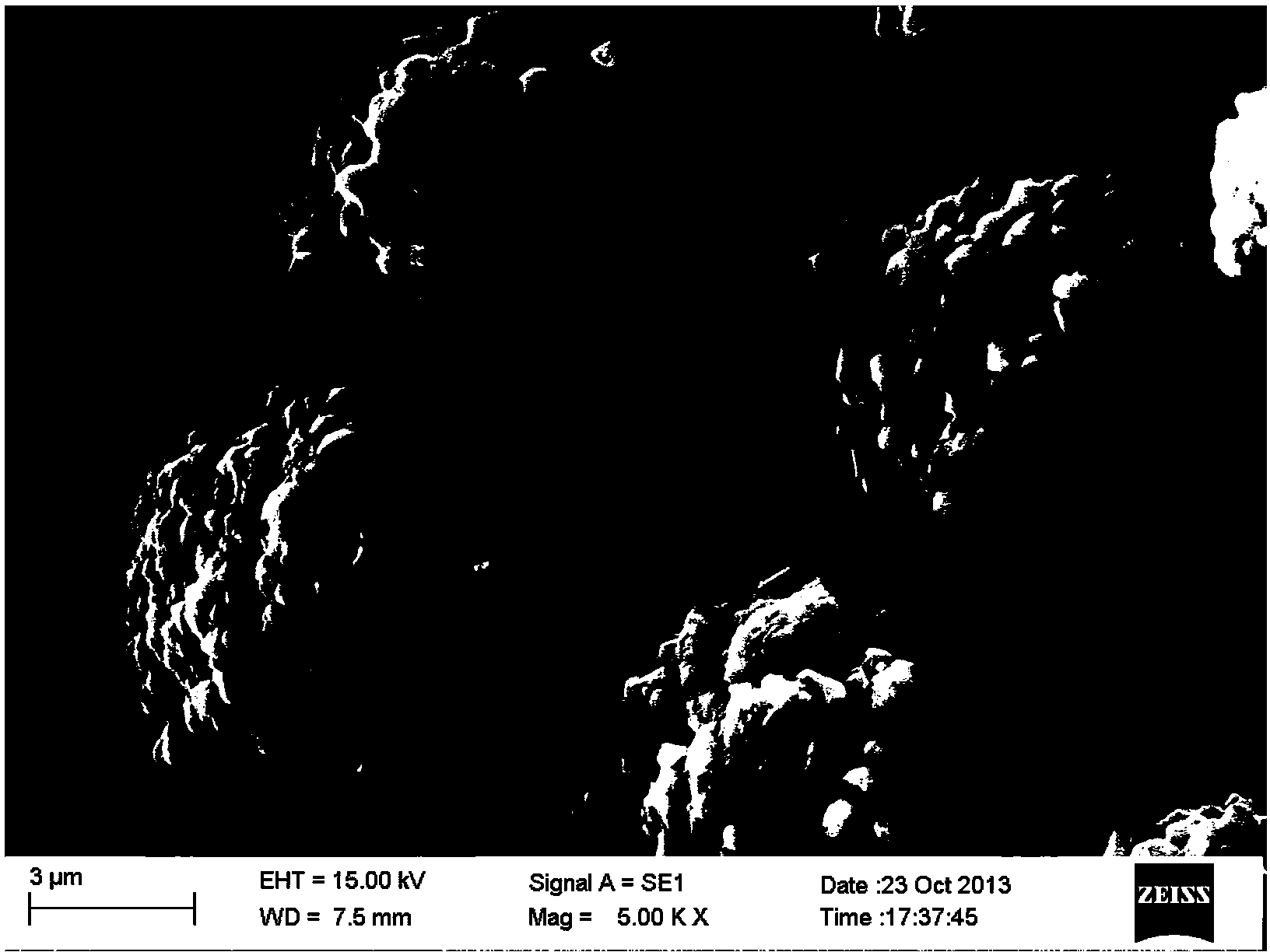

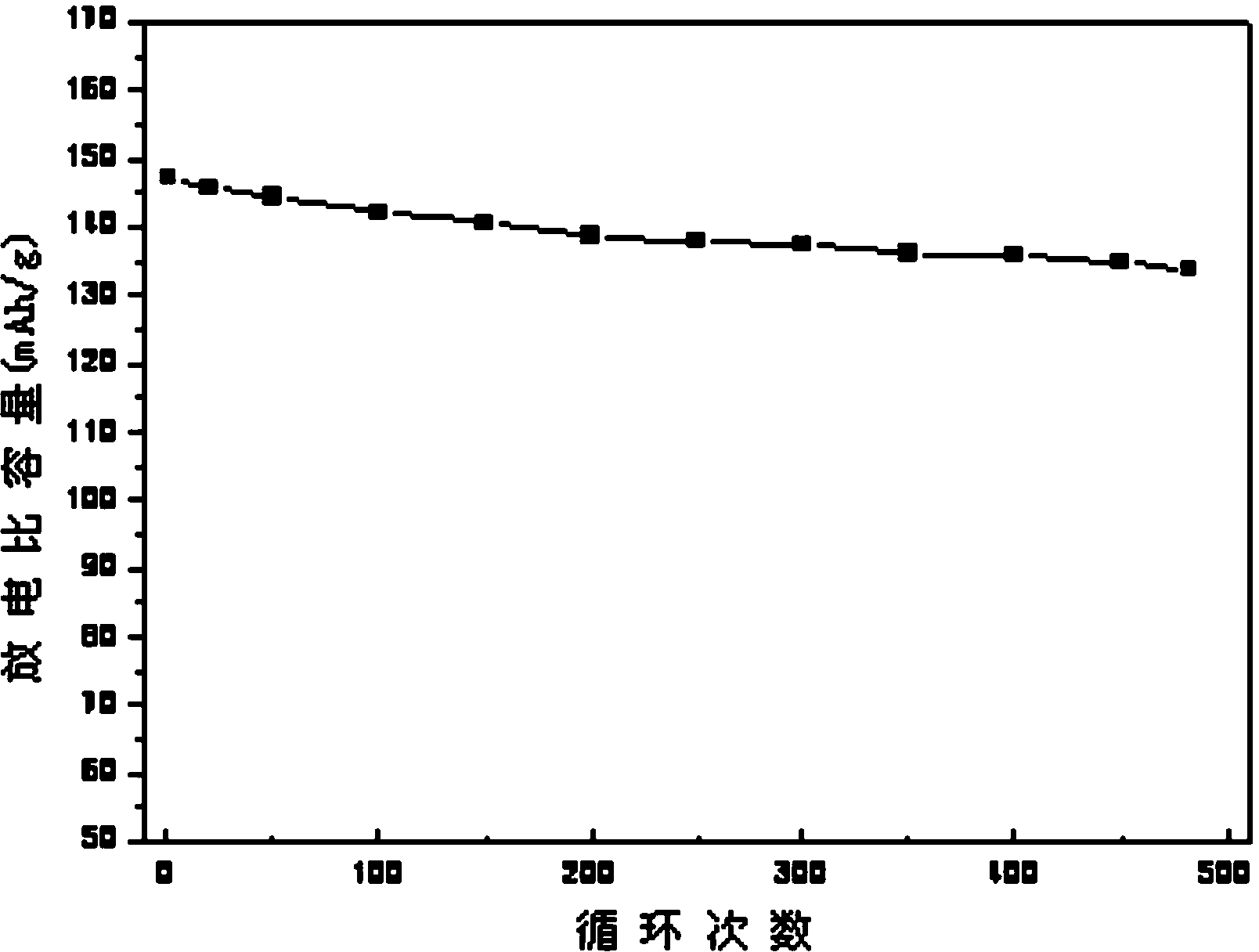

Embodiment 1

[0023] Nickel sulfate, cobalt sulfate and manganese sulfate were selected as raw materials, configured into a 2moL / L solution, and added to a four-necked flask. The rare earth salt ceric sulfate accounted for 2% of the total mass of nickel sulfate, cobalt sulfate and manganese sulfate. Then ceric sulfate was added to the solution to dissolve. Configure 15% ammonia water and 4moL / L sodium hydroxide. The ratio of ammonia water to the total molar amount of nickel, cobalt and manganese in nickel sulfate, cobalt sulfate and manganese sulfate solution is 0.2:1.

[0024] The prepared ammonia water was dripped into the solution with a constant pressure funnel, and complexed for 50 minutes. Sodium hydroxide was then added dropwise to control the pH of the solution to be about 12. After aging for 10 hours, the filtered precursor was vacuum dried for 5 hours.

[0025] The dried precursor is mixed with lithium carbonate according to a certain ratio, and mixed by wet mechanical ball mil...

Embodiment 2

[0029] Select nickel sulfate, cobalt sulfate and manganese sulfate as raw materials, prepare a 2moL / L solution, and add it to a four-necked flask. The rare earth salt lanthanum nitrate accounts for 2% of the total mass of nickel sulfate, cobalt sulfate and manganese sulfate. Lanthanum nitrate was then added to the solution to dissolve. Configure 15% ammonia water and 4moL / L sodium hydroxide. The ratio of ammonia water to the total molar amount of nickel, cobalt and manganese in nickel sulfate, cobalt sulfate and manganese sulfate solution is 0.5:1.

[0030] The prepared ammonia water was dripped into the solution with a constant pressure funnel, and complexed for 50 minutes. Sodium hydroxide was then added dropwise to control the pH of the solution to be about 12. After aging for 10 hours, the filtered precursor was vacuum dried for 5 hours.

[0031] The dried precursor is mixed with lithium hydroxide according to a certain ratio, and mixed by wet mechanical ball milling. ...

Embodiment 3

[0034] Select nickel sulfate, cobalt sulfate and manganese sulfate as raw materials, prepare a 2moL / L solution, and add it to a four-necked flask. The rare earth salts of ceric sulfate and lanthanum nitrate account for 2% of the total mass of nickel sulfate, cobalt sulfate and manganese sulfate. Then ceric sulfate and lanthanum nitrate were added to the solution to dissolve. Configure 15% ammonia water and 4moL / L sodium hydroxide. The ratio of ammonia water to the total molar amount of nickel, cobalt and manganese in nickel sulfate, cobalt sulfate and manganese sulfate solution is 1.0:1.

[0035] The prepared ammonia water was dripped into the solution with a constant pressure funnel, and complexed for 50 minutes. Sodium hydroxide was then added dropwise to control the pH of the solution to be about 12. After aging for 10 hours, the filtered precursor was vacuum dried for 5 hours.

[0036] The dried precursor is mixed with lithium hydroxide according to a certain ratio, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com