Method for manufacturing quasi-three-dimensional micron-nanometer column array

A technology of nano-column array and production method, which is applied in the field of production of three-dimensional nanostructures, can solve the problems of damage to template molded products, waste of mold materials, difficulty in separating templates and molded products, etc., to ensure complete and long-lasting use, and reduce batch preparation Cost, the effect of reducing the number of copies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: (heating-cooling molding)

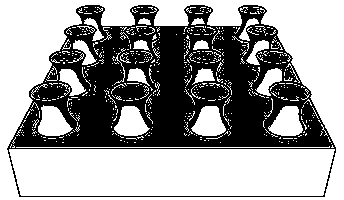

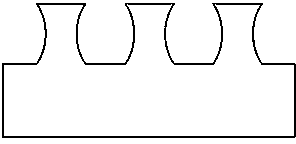

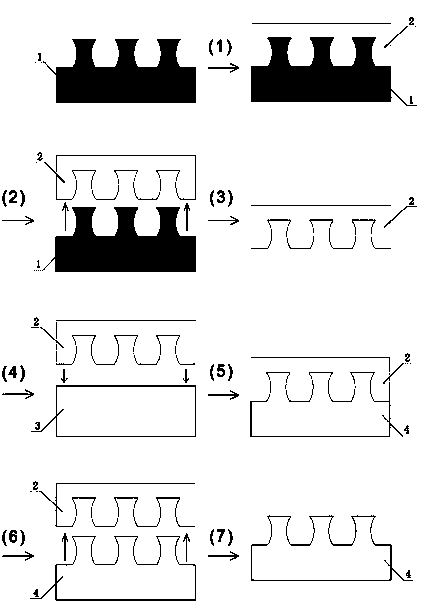

[0032] Such as figure 1 , 2 , 3 and 4, what the present invention exemplifies is a processing method for an ordered array of micron or nanometer cylinders whose middle part is thinner than the upper and lower bottoms. figure 1 with 2 is a three-dimensional structure diagram and a schematic diagram of a longitudinal section structure of the obtained molded product; image 3 Shown is the processing method flow chart; Figure 4 Shown is the SEM image of the obtained micro-nano structure.

[0033] The preparation method comprises the following steps:

[0034] The first step is the fabrication of a silicone elastomer (polydimethylsiloxane elastomer) template. exist image 3 In the shown embodiment, other processing methods (electron beam etching, special photolithography, template method or chemical etching method, etc.) , the size of the nanostructure is 100 nm-500 μm), and then the prepared polydimethylsilox...

Embodiment 2

[0037] Embodiment 2: (thermocompression forming)

[0038] The first step is the same as in Example 1.

[0039] The second step adopts the mechanical thermocompression forming method. exist image 3 In the shown embodiment, a flat-plate hot-pressing device is used, the heating temperature is set at 50-230 °C, and the upper surface of the polystyrene board is uniformly hot-pressed with a polydimethylsiloxane elastic hot-press template. After 30 min, the polydimethylsiloxane template and the polystyrene plate were taken out at the same time, and after cooling to room temperature, the polydimethylsiloxane template was separated from the finished product to obtain a plastic micro- and nano-column array structure.

[0040] The final shape of the cylinder is as Figure 5 shown.

Embodiment 3

[0041] Embodiment 3: (casting molding)

[0042] The first step is the same as in Example 1.

[0043] The second step adopts pouring molding. and image 3 The example implementation shown is slightly different. First heat the polydimethylsiloxane elastic template to 80 ℃ to solidify, then cool. Then pour the polyurethane prepolymer solution on the elastic template stamp, then place it in an oven at 30 °C for 6 h, take it out after the solvent is completely volatilized, and finally peel the polyurethane material from the elastic template. A polyurethane microcolumn array with a spatula-like top was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com