Preparation method for fluorine-doped graphene material

A graphene and fluorine-doped technology, which is applied in the field of preparation of fluorine-doped graphene materials, can solve the problems of inconvenient application or modification, high preparation cost, complicated process, etc., and achieves easy large-scale industrial production and simple preparation steps , High operational controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Preparation and characterization of fluorine-doped graphene material;

[0017] Put 1.0 g of polyvinylidene fluoride powder into a corundum crucible, and move the corundum crucible into a tube furnace, raise the temperature to 600 °C at a rate of 5 °C / min in an argon atmosphere, and at 600 °C After sintering for 3 hours, the fluorine-doped graphene product is obtained.

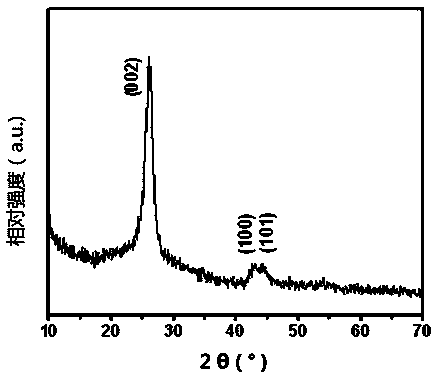

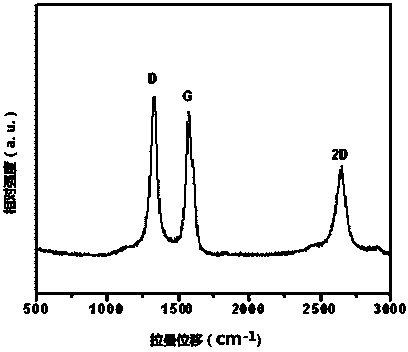

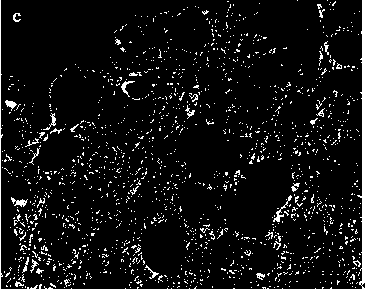

[0018] The product was identified as a graphite phase (such as figure 1 ); characterized by Raman spectroscopy as a graphitic phase (e.g. figure 2 ); JEM 1011 transmission electron micrograph ( image 3 ) and high-resolution electron microscope photos ( Figure 4 ) indicates that the obtained product is a curly film-like substance with a thickness mainly distributed in the range of about 2-4 nm.

Embodiment 2

[0019] Example 2: Put 1.0 g of polytetrafluoroethylene powder into a corundum crucible, move the corundum crucible into a tube furnace, raise the temperature to 650 °C at a rate of 5 °C / min under an argon atmosphere, and Sinter at 650°C for 3 hours to obtain fluorine-doped graphene products.

[0020] The obtained product is curly film-like graphene with a small number of layers, and the thickness is mainly distributed in 3-6 nanometers.

Embodiment 3

[0021] Example 3: Put 1.0 g of polyvinylidene fluoride powder into a corundum crucible, and move the corundum crucible into a tube furnace, raise the temperature to 650 °C at a rate of 5 °C / min under a nitrogen atmosphere, and heat it at 650 °C Sintering at ℃ for 3 hours to obtain fluorine and nitrogen doped graphene products.

[0022] The obtained product is curly film-like graphene with a small number of layers, and the thickness is mainly distributed in 3-6 nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com