Production method capable of increasing yield of neomycin

A production method and technology of neomycin, which are applied in the production field of increasing the output of neomycin, can solve the problems of production yield and production cycle limit, complex production process, long cycle and the like, and achieve small changes in production process and low production cost. , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

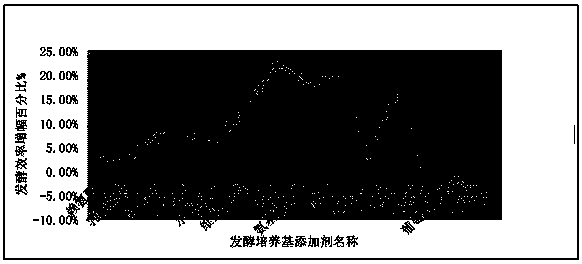

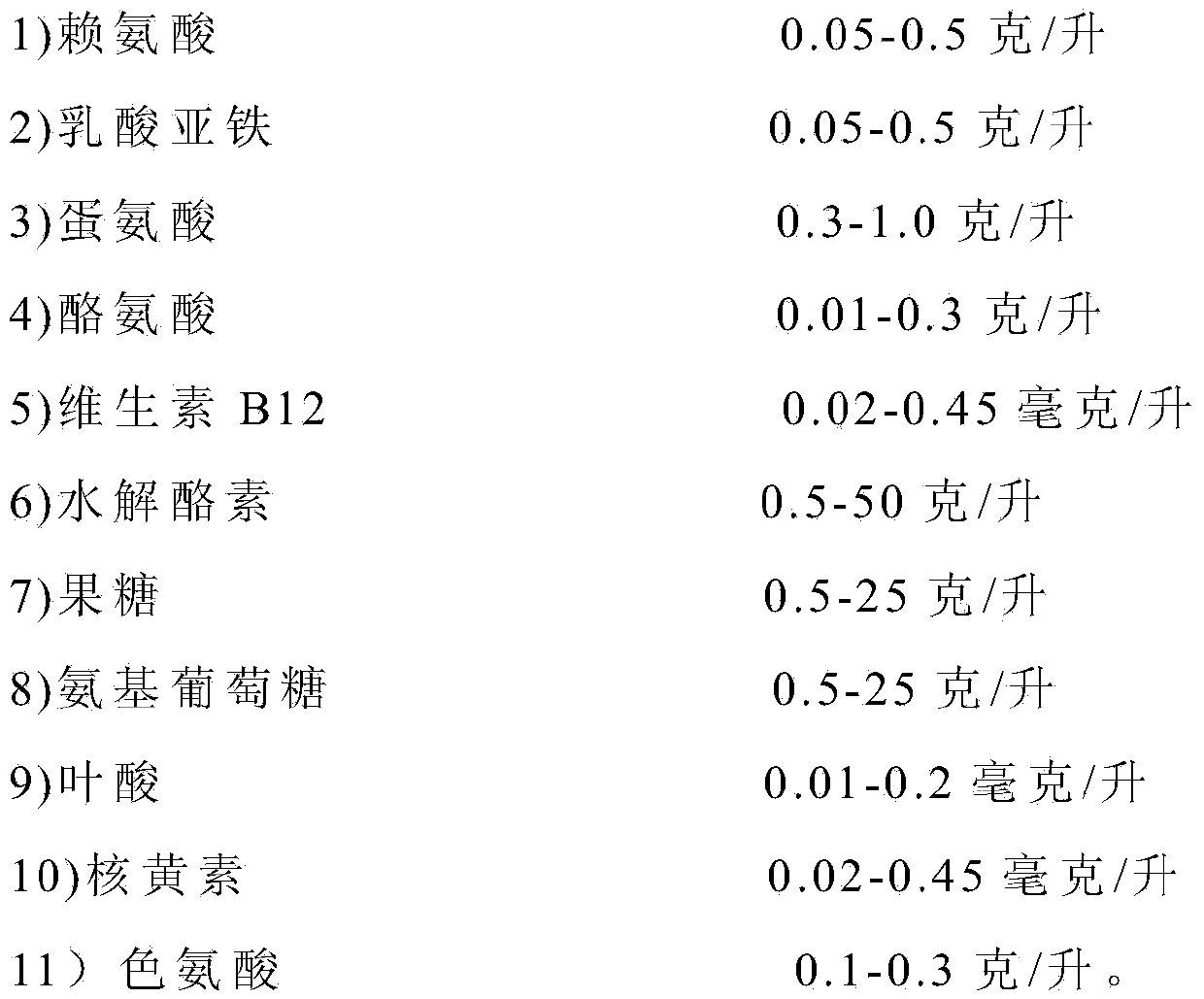

Method used

Image

Examples

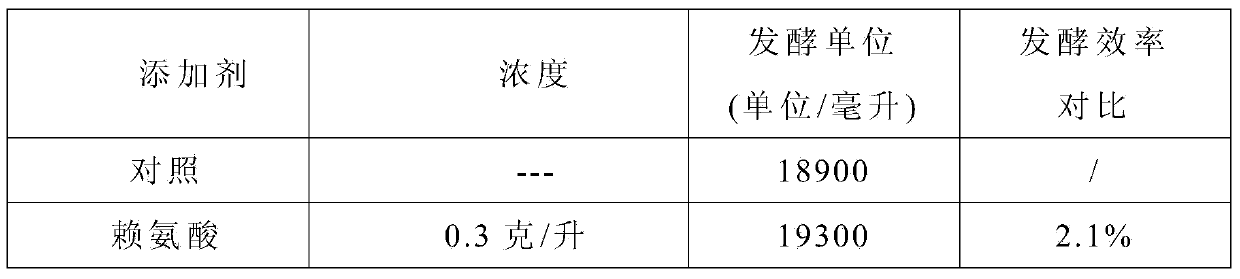

Embodiment 1

[0043] Example 1: Soybean meal powder 0.5, peanut meal powder 2.8, rice flour 5.0, yeast powder

[0044] 0.9, glucose 1.5, peptone 1.0, ammonium sulfate 0.5, sodium chloride 0.45, light calcium carbonate 0.45, KH 2 PO 4 0.06, α-amylase 0.02, soybean oil 0.12, and silicon oil 0.05 were added to the conventional fermentation medium of Streptomyces freundii, with lysine added at a concentration of 0.3 g / L, and inoculated with Streptomyces fradiae-H strain according to the conventional method ( SY060112), fermented for 130 hours at pH 7.0, culture temperature 35°C and volume 50 liters.

Embodiment approach

[0046] (1) Incline medium% (g / 100ml) formula: glucose 1.0, beef extract 0.2, agar 1.8~2.2, dipotassium hydrogen phosphate 0.05, DL-aspartin 0.05

[0047] (2) Seed bottle culture medium% (g / 100ml) formula: glucose 2.0, DL-asparagus 0.06, peptone 0.5, peanut meal powder 2.8, yeast powder 0.5, rice flour 8.0, corn steep liquor 0.25, amylase 0.0025, sulfuric acid Ammonium 0.6, light calcium carbonate 0.45

[0048] (3) Reproduction tank seed medium% (g / 100ml) formula: peanut meal 1.0, corn starch 1.0, yeast powder 2.25, glucose 2.5, peptone 0.5, ammonium sulfate 0.1, light calcium carbonate 1.4, Na 2 HPO 4 0.1, soybean oil 0.28

[0049] (4) Fermentation tank fermentation medium% (g / 100ml) formula: soybean meal 0.5, peanut meal 2.8, rice flour 5.0, yeast powder 0.9, glucose 1.5, peptone 1.0, ammonium sulfate 0.5, sodium chloride 0.45 light Calcium carbonate 0.45, KH 2 PO 4 0.06, α-amylase 0.02, soybean oil 0.12, silicone oil 0.05, lysine concentration 0.03

[0050] (5) Preparation of incli...

Embodiment 2

[0060] Example 2: The additive is ferrous lactate with a concentration of 0.6 g / L, instead of the lysine concentration of 0.3 g / L in Example 1. The medium composition and dosage, and fermentation conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com