Treatment method for p-beta hydroxyethyl sulfone acetanilide mother liquor waste water

A technology of hydroxyethyl sulfone acetanilide mother and treatment method is applied in the field of treatment of p-β hydroxyethyl sulfone acetanilide mother liquor wastewater, and achieves the effects of good dyeing performance, high reactivity and good lifting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

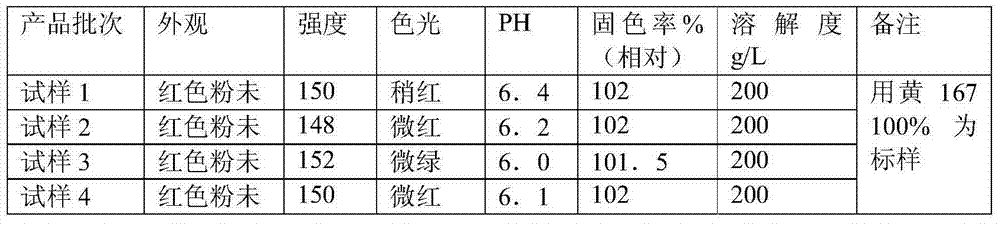

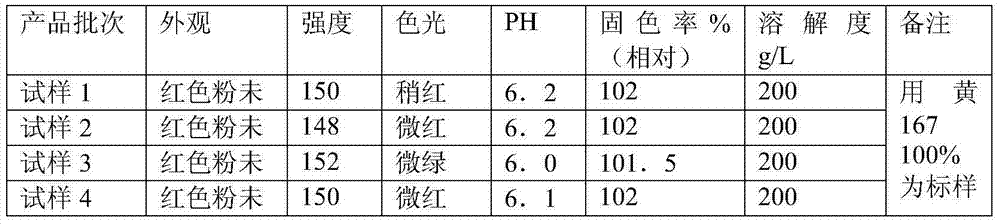

Examples

Embodiment 1

[0038] 1), the pretreatment of p-β hydroxyethyl sulfone acetanilide mother liquor water:

[0039] Weigh 2500g of p-β-hydroxyethyl sulfone acetanilide mother liquid wastewater, add 130g of sulfuric acid with a mass concentration of 98% and heat up to 100°C for hydrolysis for 3 hours, after the hydrolysis is completely controlled by high-efficiency liquid phase, add an appropriate amount of liquid alkali to neutralize pH=6, neutralize The processed material enters the MVR evaporative crystallization system for desalting and concentration at the same time until the amino value reaches 16% (the main component is p-β-hydroxyethyl sulfone aniline).

[0040] 2), heavy nitrogen:

[0041] Diazo: Add 30g of water and 30g of crushed ice to a 500ml beaker, add 87.85g of K acid, beat at 0-5°C for 1 hour to obtain K acid solution, weigh 11.85g of sodium nitrite, add 50g of water and stir to dissolve, then dropwise add K acid solution During the feeding process, keep the temperature at 0-5°...

Embodiment 2

[0053] 1), the pretreatment of p-β hydroxyethyl sulfone acetanilide mother liquor water:

[0054] Weigh 2500g of p-β-hydroxyethyl sulfone acetanilide mother liquid wastewater, add 120g of sulfuric acid with a mass concentration of 98% and heat up to 90°C for 3.5 hours to hydrolyze. The processed material enters the MVR evaporative crystallization system for desalting and concentration at the same time until the amino value reaches 16% (the main component is p-β-hydroxyethyl sulfone aniline).

[0055] 2), heavy nitrogen:

[0056] Diazo: Add 25g of water and 30g of crushed ice to a 500ml beaker, put in 80.85g of K acid, beat at a temperature of 0-5°C for 1.5h to obtain a K acid solution, weigh 10.9g of sodium nitrite, add 50g of water and stir to dissolve, then add K In the acid solution, keep the temperature at 0-5°C during the feeding process, the Congo red test paper will appear blue, and the starch potassium iodide test paper will appear blue. After adding and reacting for...

Embodiment 3

[0067] 1), the pretreatment of p-β hydroxyethyl sulfone acetanilide mother liquor water:

[0068] Weigh 2500g of p-β-hydroxyethyl sulfone acetanilide mother liquor wastewater, add 140g of sulfuric acid with a mass concentration of 98% and heat up to 100°C for 3 hours for hydrolysis, after the hydrolysis is completely controlled by high-efficiency liquid phase, add an appropriate amount of liquid alkali to neutralize pH=6, neutralize The processed material enters the MVR evaporative crystallization system for desalting and concentration at the same time until the amino value reaches 16% (the main component is p-β-hydroxyethyl sulfone aniline).

[0069] 2), heavy nitrogen:

[0070] Diazo: Add 35g of water and 30g of crushed ice to a 500ml beaker, add 90.35g of K acid, beat at 0-5°C for 1 hour to obtain K acid solution, weigh 12.2g of sodium nitrite, add 50g of water and stir to dissolve, then dropwise add K acid In the solution, keep the temperature at 0-5°C during the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com