Hydrothermal preparation method of nano lithium iron manganese phosphate anode material

A lithium iron manganese phosphate, cathode material technology, applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of easy decomposition of manganese element, low conductivity, etc., achieve good crystallinity, improve conductivity, and purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

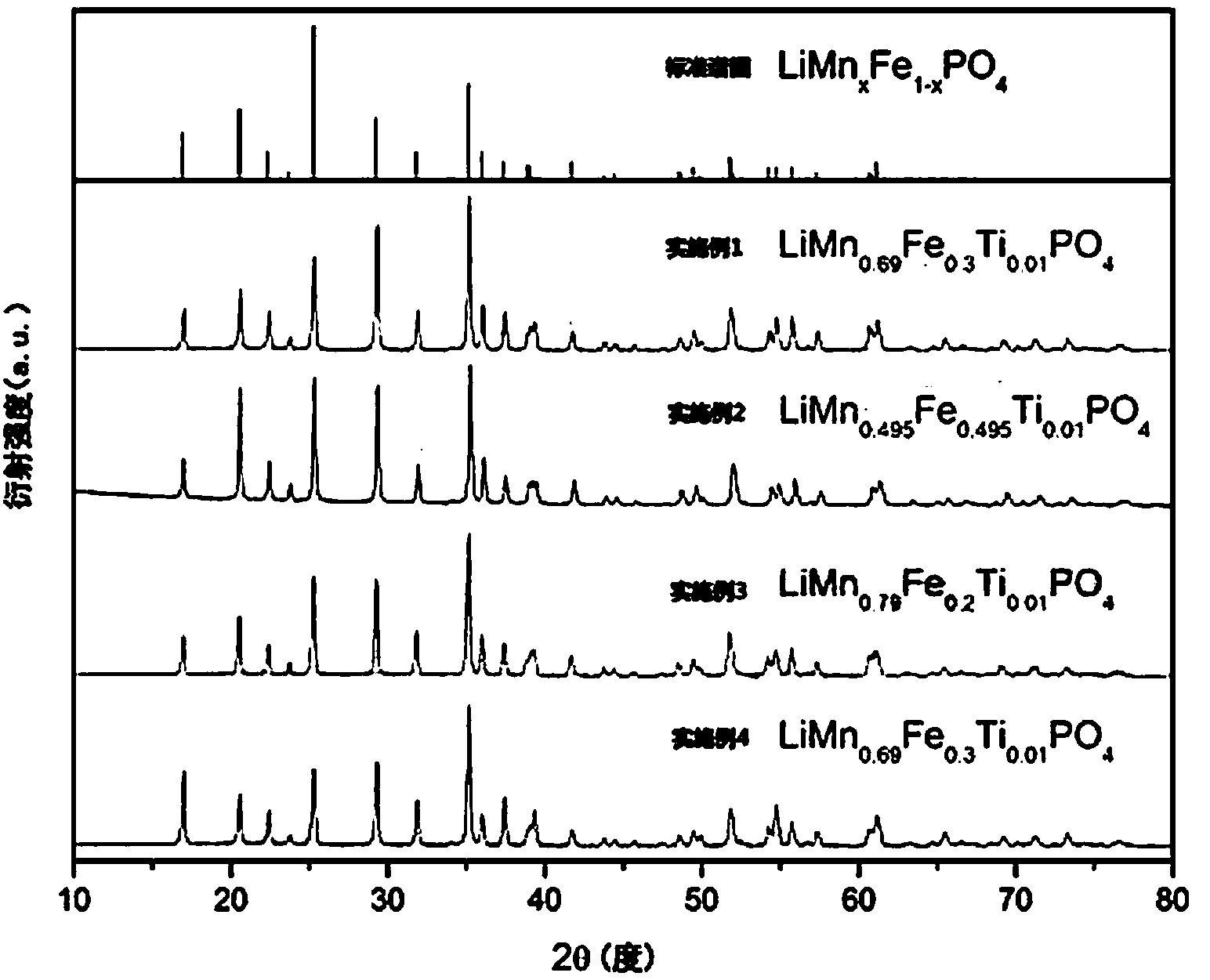

Embodiment 1

[0019] Add 2L of deionized water into the sealed reaction kettle, add 6.0mol LiOH·H 2 O and 2.0mol 85%H 3 PO 4 Add to the reaction kettle respectively, add while stirring, and then add concentrated ammonia water with a mass fraction of 25% into the reaction kettle to control the pH value in the reaction kettle within the range of 9 to 10, and seal the reaction kettle. At the same time, the temperature was raised to 180°C, and 0.6mol FeSO 4 ·7H 2 O, 1.38mol MnSO 4 ·H 2 O and 0.02mol Ti (SO 4 ) 2 Add it into 2L of deionized water, stir evenly, pump the solution into the reaction kettle with a high-pressure pump, and control the addition speed so that the temperature in the reaction kettle is within the range of 170-200°C during the addition process. The reaction kettle was heated, and the temperature in the reaction kettle was raised to 200° C. for 10 hours. After cooling, when the reaction kettle is cooled below 60°C, wash the material with deionized water until there i...

Embodiment 2

[0024] Add 2L of deionized water into the sealed reaction kettle, add 6.0mol LiOH·H 2 O and 2.0mol 85%H 3 PO 4 Add to the reaction kettle respectively, add while stirring, and then add concentrated ammonia water with a mass fraction of 25% into the reaction kettle to control the pH value in the reaction kettle within the range of 9 to 10, and seal the reaction kettle. The closed reaction kettle was heated to 180°C at the same time, and 0.99mol FeSO 4 ·7H 2 O, 0.99mol MnSO 4 ·H 2 O and 0.02mol Ti (SO 4 ) 2 Add it into 2L of deionized water, stir evenly, pump the solution into the reaction kettle with a high-pressure pump, and control the addition speed so that the temperature in the reaction kettle is within the range of 170-200°C during the addition process. The reaction kettle was heated, and the temperature in the reaction kettle was raised to 200° C. for 10 hours. After cooling, when the reaction kettle is cooled below 60°C, wash the material with deionized water un...

Embodiment 3

[0027] Add 2L of deionized water into the sealed reaction kettle, add 6.0mol LiOH·H 2 O and 2.0mol 85%H 3 PO 4 Add to the reaction kettle respectively, add while stirring, and then add concentrated ammonia water with a mass fraction of 25% into the reaction kettle to control the pH value in the reaction kettle within the range of 9 to 10, and seal the reaction kettle. The closed reaction kettle was heated to 180°C at the same time, and 0.4mol FeSO4 ·7H 2 O, 1.58mol MnSO 4 ·H 2 O and 0.02mol Ti (SO 4 ) 2 Add it into 2L of deionized water, stir evenly, pump the solution into the reaction kettle with a high-pressure pump, and control the addition speed so that the temperature in the reaction kettle is within the range of 170-200°C during the addition process. The reaction kettle was heated, and the temperature in the reaction kettle was raised to 200° C. for 10 hours. After cooling, when the reaction kettle is cooled below 60°C, wash the material with deionized water until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com