Dry powder extinguisher containing modified smectite powder

A dry powder fire extinguishing agent, montmorillonite powder technology, applied in fire protection equipment and other directions, can solve the problems of poor cooling performance and re-ignition resistance, poor fire extinguishing effect, limited fire extinguishing effect, etc. The effect of thermal expansion rate and hydrophobic and oleophobic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

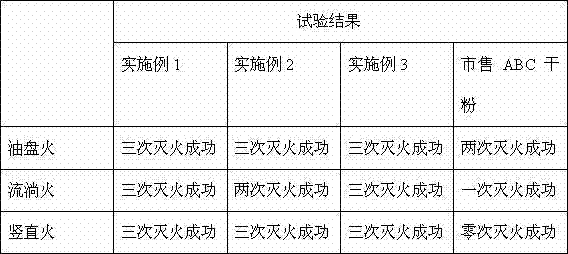

Examples

Embodiment 1

[0014] A dry powder fire extinguishing agent containing modified montmorillonite powder, made of the following raw materials in parts by weight: 80 parts of modified montmorillonite powder, 7 parts of mica powder, 13 parts of hydrated zinc sulfide, 5 parts of calcium hydroxide, stearic acid 6 parts of magnesium, 5 parts of nitrogen-containing silicon oil, 2 parts of expandable graphite, 3 parts of magnesite, 3 parts of urea, 6 parts of calcium lignosulfonate, 4 parts of bamboo charcoal fiber, 2 parts of industrial essence, 3 parts of zinc borate, chlorine 2 parts of paraffin, 8 parts of diatomaceous earth.

[0015] Wherein, the modified montmorillonite powder is prepared by the following method: calcining the montmorillonite at a temperature of 700° C. for 3 hours, soaking it in 12% hydrochloric acid solution for 3 hours, washing it with deionized water to neutrality, and drying it. Then add charcoal powder equivalent to 2% of the powder weight, 4% cetyltrimethylammonium bromi...

Embodiment 2

[0018] A dry powder fire extinguishing agent containing modified montmorillonite powder, 70 parts of modified montmorillonite powder, 6 parts of mica powder, 10 parts of zinc sulfide hydrate, 3 parts of calcium hydroxide, 7 parts of magnesium stearate, and 3 parts of nitrogen-containing silicone oil , 2 parts of expandable graphite, 3 parts of magnesite, 2 parts of urea, 7 parts of calcium lignosulfonate, 3 parts of bamboo charcoal fiber, 2 parts of industrial essence, 2 parts of zinc borate, 1 part of chlorinated paraffin, diatomaceous earth 8 servings.

[0019] Wherein, the modified montmorillonite powder is prepared by the following method: calcining the montmorillonite at a temperature of 600° C. for 4 hours, soaking it in 10% hydrochloric acid solution for 4 hours, washing it with deionized water to neutrality, and drying it. Then add charcoal powder equivalent to 1% of the powder weight, 3% cetyltrimethylammonium bromide, and 4% 2-bromo-3,3,3-trifluoropropene. Stir for ...

Embodiment 3

[0022] A dry powder fire extinguishing agent containing modified montmorillonite powder, made of the following raw materials in parts by weight: 90 parts of modified montmorillonite powder, 10 parts of mica powder, 15 parts of hydrated zinc sulfide, 5 parts of calcium hydroxide, stearic acid 8 parts of magnesium, 5 parts of nitrogen-containing silicon oil, 3 parts of expandable graphite, 3 parts of magnesite, 3 parts of urea, 6 parts of calcium lignosulfonate, 5 parts of bamboo charcoal fiber, 3 parts of industrial essence, 4 parts of zinc borate, chlorine 3 parts of paraffin, 10 parts of diatomaceous earth.

[0023] Wherein, the modified montmorillonite powder is prepared by the following method: calcining the montmorillonite at a temperature of 800° C. for 3 hours, soaking it in 12% hydrochloric acid solution for 3 hours, washing it with deionized water to neutrality, and drying it. Then add charcoal powder equivalent to powder weight%, 4% cetyltrimethylammonium bromide, 4% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com