Protective agent for sulfur-tolerant shift catalyst and preparation method thereof

A sulfur-resistant conversion and protective agent technology, which is applied in catalyst protection, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited protection ability of conversion catalysts, achieve good adsorption and detoxification, large pore volume, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

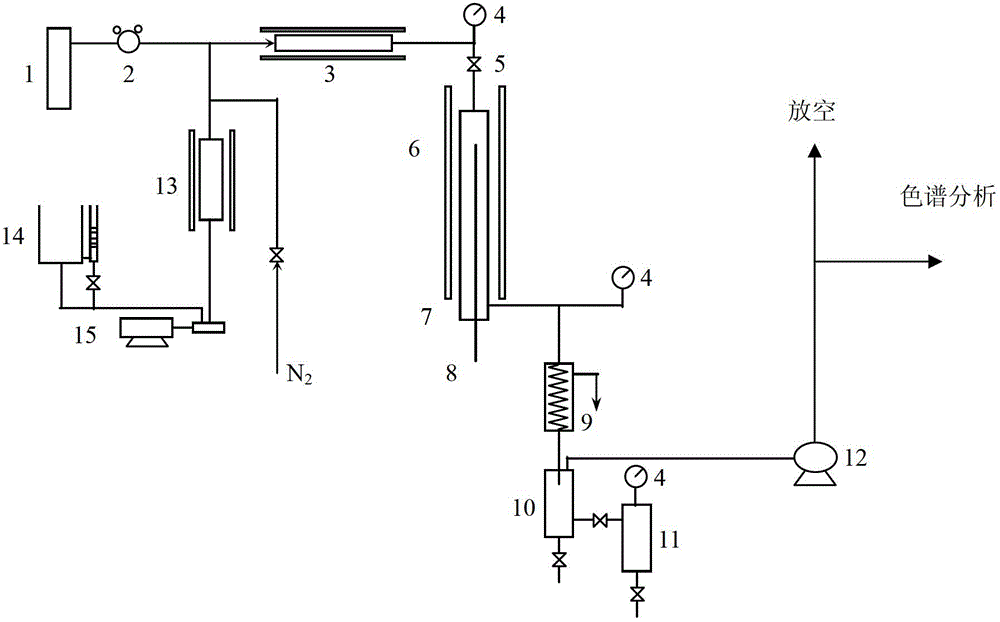

Method used

Image

Examples

Embodiment 1

[0047] The attapulgite clay was first dried at 150°C for 6 hours, and then crushed through a 180-mesh sieve.

[0048] Weigh 12.08g of copper nitrate and 19.45g of nickel nitrate and dissolve in 45ml of deionized water to obtain solution A; weigh 5.5g of zirconium oxychloride, 1.0g of citric acid and 3.0g of oxalic acid into 20ml of deionized water to obtain solution B.

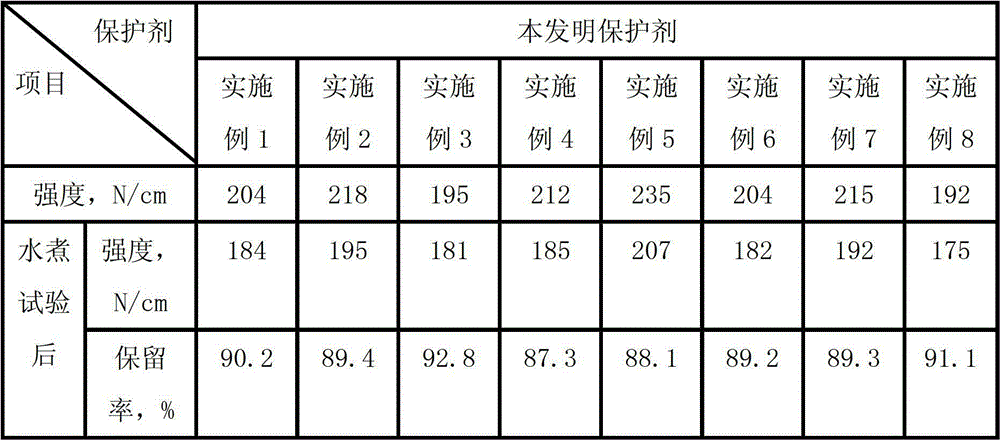

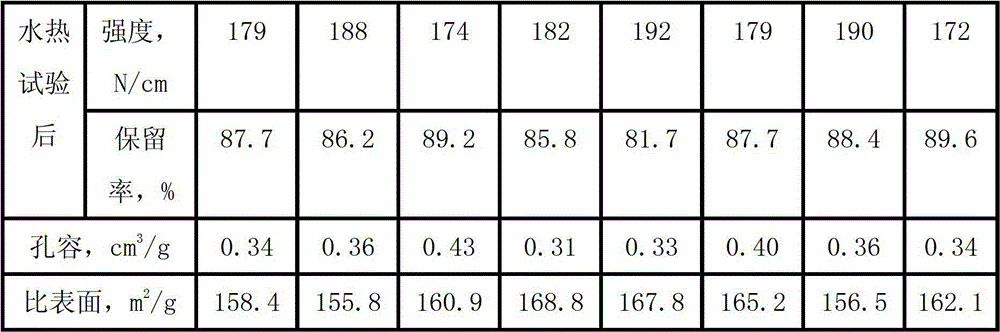

[0049] Weigh 79g of attapulgite clay, 10.0g of magnesia, 3.0g of turnip powder and mix evenly, add solution A, knead evenly; then add solution B, knead, shape, dry naturally, roast at 530°C for 3h, then cool down naturally to room temperature. That is, the finished bar-shaped sulfur-resistance transforming protective agent C-1 is obtained. Its strength and strength stability are shown in Table 1.

Embodiment 2

[0051] Dry the attapulgite clay at 110°C for 10 hours, and then crush it through a 160-mesh sieve.

[0052] Weigh 4.53g of copper nitrate and 23.34g of nickel nitrate and dissolve them in 45ml of deionized water to obtain solution A; weigh 4.1g of zirconium oxychloride and 3.0g of oxalic acid and add them to 20ml of deionized water to obtain solution B.

[0053] Weigh 76g of attapulgite clay, 15.0g of magnesia, 6.0g of turnip powder and mix evenly, add solution A, knead evenly; then add solution B, knead, shape, dry naturally, roast at 420°C for 4h, then cool down naturally to room temperature. That is to obtain the finished four-leaf clover-shaped sulfur-resistant conversion protective agent C-2. Its strength and strength stability are shown in Table 1.

Embodiment 3

[0055] The attapulgite clay was first dried at 160°C for 8 hours, and then crushed through a 160-mesh sieve.

[0056] Weigh 24.16g of copper nitrate and 7.78g of nickel nitrate and dissolve in 40ml of deionized water to obtain solution A; weigh 3.6g of zinc nitrate and 3.0g of oxalic acid and add them to 20ml of deionized water to obtain solution B.

[0057] Weigh 84g of attapulgite clay, 5.0g of magnesia, 3.0g of turnip powder and mix evenly, add solution A, knead evenly; then add solution B, knead, shape, dry naturally, roast at 500°C for 3h, then cool down naturally to room temperature. That is, the finished bar-shaped sulfur-resistant conversion protective agent C-3 is obtained. Its strength and strength stability are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com