Hydration absorption gas stripping device and method for recycling ethylene and ethane from catalytic cracking dry gas or ethylene cracking gas

A technology of hydration absorption and catalytic cracking, which is applied in chemical instruments and methods, ethylene production, hydrocarbons, etc., to achieve the effects of reduced process energy consumption, reduced investment costs, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

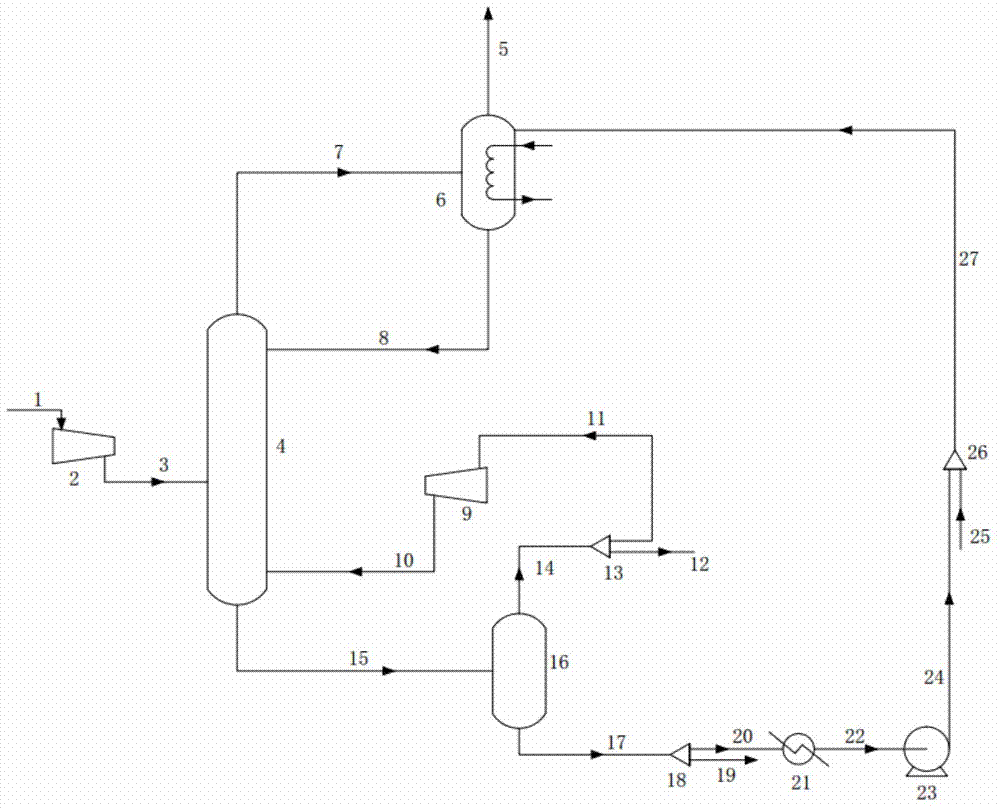

Method used

Image

Examples

Embodiment 1

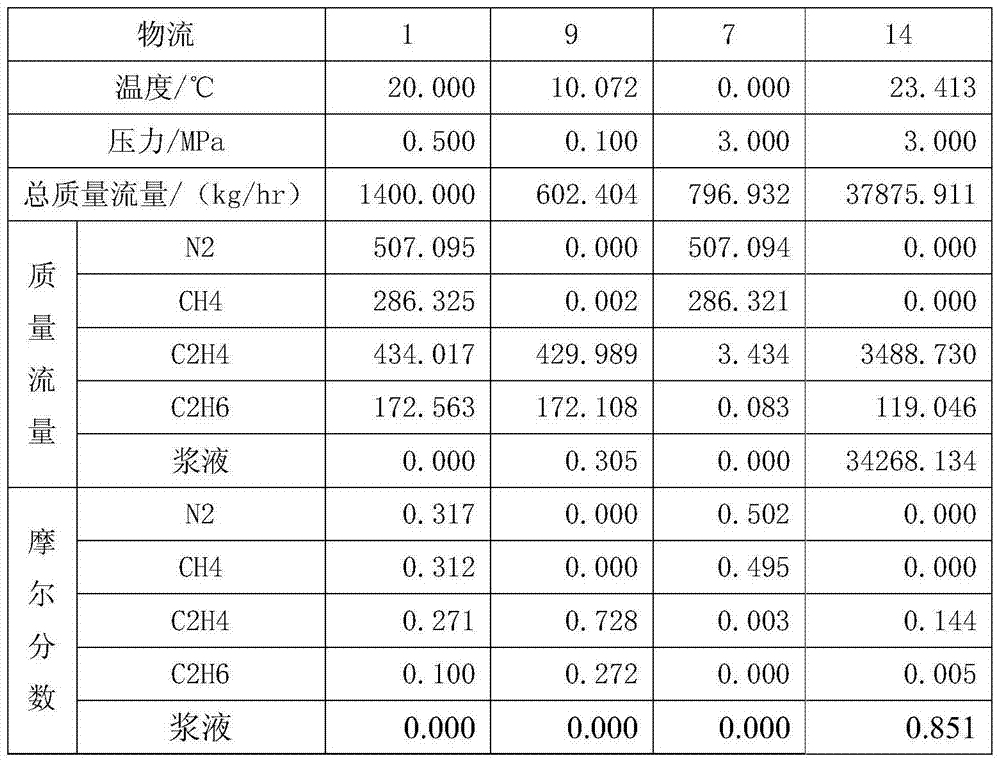

[0027] The molar composition of raw material gas 1 is 31.7%N2+32.1%CH4+27.1%C2H4+10.0%C2H6, the mass flow rate is 1400kg / hr, and the temperature is 20°C. Diesel oil and water are used as slurry in the process, and the mass flow rate of the total circulating slurry 27 is 37875.911kg / hr. Under standard conditions, the gas-liquid ratio in the hydration reactor 6 is 100:1.

[0028] The compressor 2 compresses the feed gas 1 to 3Mpa, the hydration absorption tower 4 operates at 3Mpa, the total balance stage is 15, and the compressed feed gas is fed in the 8th stage. The hydrate decomposer 16 is adiabatically flashed at 0.1Mpa to decompose. The heat exchanger 21 cools the internal circulating slurry 20 to 0°C, and the hydrate reactor 6 operates at 0°C and 3Mpa. The stripping compressor compresses the reflux to 3Mpa and enters from the bottom of the hydration absorption tower 4 . The results of the separation are shown in Table 1. Table 1 shows that the mole fraction of C2+ in th...

Embodiment 2

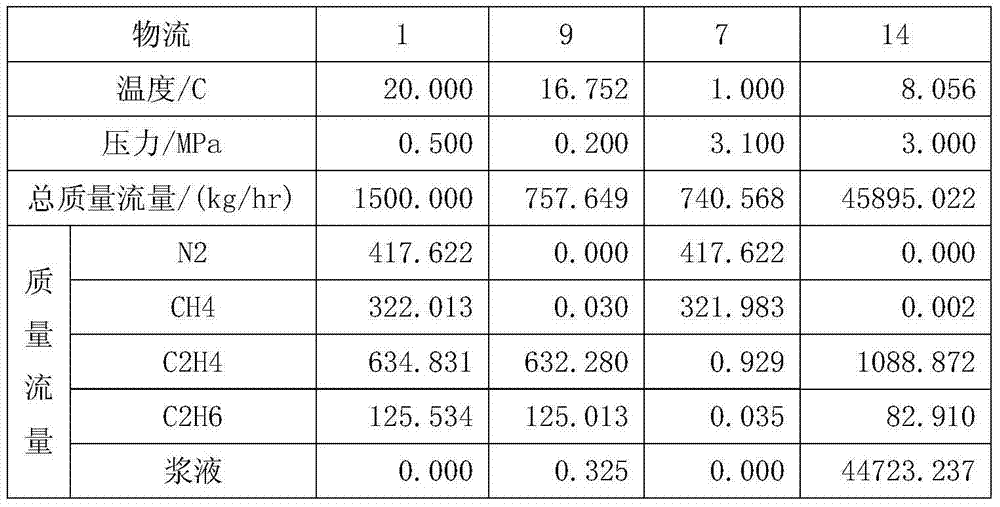

[0032] The molar composition of raw material gas 1 is 24.1%N2+32.5%CH4+36.6%C2H4+6.8%C2H6, the mass flow rate is 1500kg / hr, and the temperature is 20°C. Diesel oil and water are used as slurry in the process, and the mass flow rate of the total circulating slurry 27 is 45895.022kg / hr.

[0033] The compressor 2 compresses the feed gas 1 to 3.1Mpa, the hydration absorption tower 4 operates at 3.1Mpa, the total balance stage is 12, and the compressed feed gas is fed in the sixth stage. The hydrate decomposer 16 is adiabatically flashed at 0.2Mpa to decompose. The heat exchanger 21 cools the internal circulating slurry 20 to 1°C, and the hydrate reactor 6 operates at 1°C and 3.1Mpa. The stripping compressor compresses the reflux to 3.1Mpa and enters from the bottom of the hydration absorption tower 4 . The separation results are shown in Table 2. Table 2 shows that the mole fraction of C2+ in the product gas 12 is above 99.9%, and the recovery rate is above 99.5%, realizing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com