Purification method for Nemadectin

A purification method and organic solvent technology, applied in the field of animal pharmacy, can solve the problems of high recovery cost of rectification, expensive chromatography column, high one-time investment, reduce energy consumption and production cost, facilitate the expansion of production scale and equipment. low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

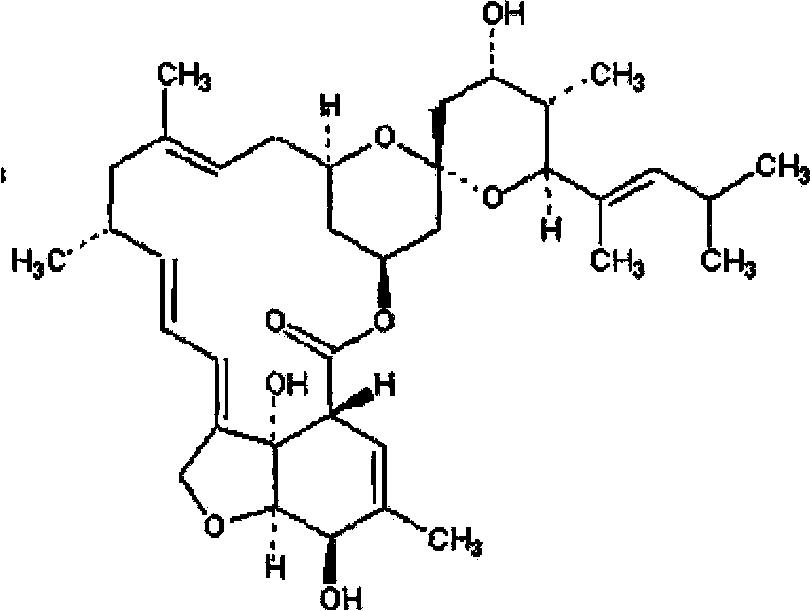

Image

Examples

Embodiment 1

[0033] 1. After the streptomycin fermentation broth is put into the tank, an anionic polyacrylamide flocculant solution is added to it, and added according to the ratio of 0.01 to 0.02 g / L fermentation broth, stirred evenly, press-filtered, topped with water, and dried to obtain 4285g of fungus residue, wherein the content of nemoctine is 60g, and the content is 57%.

[0034] 2. Use 25L of 60% aqueous ethanol solution to carry out stirring extraction on the filter press bacterial residue, the extraction temperature is 40-50° C., extract for 4 hours and then separate. A total of three extractions were performed. The first two mergers have a total of 54g of nemoctine, with a content of 68%; the third time is applied to the next Yicui.

[0035] 3. After combining the two extracts, add water, reduce the concentration of ethanol to 40-50%, then add 13L of dichloromethane for extraction, stir and extract for 2 hours, then stand and separate. Extraction was done twice, the second h...

Embodiment 2

[0039] 1. After putting the streptomycin fermentation broth into the tank, add polyaluminum sulfate solution in a ratio of 0.1 to 0.5g / L fermentation broth, stir evenly, press filter, top water, and dry to obtain 3856g of fungus residue , wherein the content of nemoctine is 46g, and the content is 60%.

[0040] 2. Use 20 L of 40% acetone aqueous solution to carry out stirring extraction on the filter press bacterial residue, the extraction temperature is 40-50° C., extract for 4 hours and then separate. A total of three extractions were performed. The first two mergers have a total of 42g of nemoctine, with a content of 71%; the third time is applied to the next Yicui.

[0041] 3. Combine the two extracts, add water, reduce the concentration of acetone to 30%, then add 20 L of toluene for extraction, stir and extract for 2 hours, and then stand for separation. Extracted twice, the second toluene extraction was used for the next extraction.

[0042] 4. Concentrate the toluen...

Embodiment 3

[0045] 1. After the streptomycin fermentation broth is put into the tank, add calcium chloride-sodium dihydrogen phosphate combined solution, add according to the ratio of 10g calcium chloride+6g disodium hydrogen phosphate / L fermentation broth, stir evenly and press Filter, top water, blow dry, obtain bacterium residue 4025g, wherein the content of nimoctine is 52g, and content is 58%.

[0046] 2. Use 20 L of 80% methanol aqueous solution to carry out stirring extraction on the filter press bacterial residue, the extraction temperature is 40-50° C., extract for 4 hours and then separate. A total of three extractions were performed. The first two mergers have a total of 50 g of nemoctine, with a content of 66%; the third time is applied to the next Yicui.

[0047] 3. After combining the two extracts, add water, reduce the concentration of methanol to 40-50%, and then add 10 L of ethyl acetate for extraction, stir and extract for 2 hours, then stand and separate. Extract twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com