The method of non-vacuum preparation of nanometer film with metal compound as precursor

A metal compound and nano-film technology, which is applied in the field of vacuum preparation of nano-film, can solve the problems that cannot meet industrial production, the preparation process is not very mature, and the output of metal compound film is low, so as to achieve good film grain growth and good film quality , the effect of large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

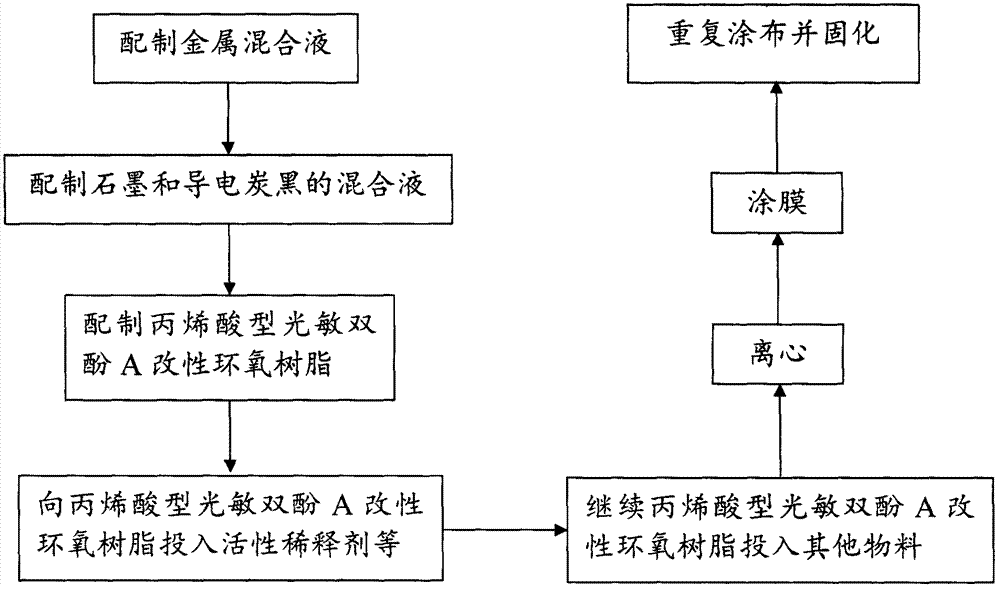

Method used

Image

Examples

Embodiment Construction

[0030] The present invention discloses a non-vacuum preparation method of nano film by using a metal compound as a precursor, which comprises the following steps:

[0031] S1. Prepare a mass fraction of 40% metal particle powder with a particle size of 500-700nm and a mass fraction of 60% metal particle powder with a particle size of 44-48μm into a metal particle liquid with a mass fraction of 30-40%: Put the metal particles into a jet mill for dry grinding for 1-4 hours, with a classification speed of 3500 rpm, ultrasonic cleaning, and drying for 15 minutes to obtain powder metal particles with D50 = 5 μm and D97 = 60 μm, and then classify 5-10 μm powder The powder metal particles are dissolved in 60-70% deionized water with a mass fraction of 60-70% deionized water, ultrasonically stirred, shaken, and separated for 20-30 minutes to obtain a 5-10 μm metal powder solution for later use.

[0032] Parameters of jet mill: The compressed air flow rate in jet mill is 60m / min, the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com