Metal chelating agent, preparation method and application thereof, and catalytic cracking method

A technology of metal trapping agent and catalytic cracking, which is applied in the field of metal trapping agent, can solve the problems that the catalytic cracking unit cannot be implemented and the process is complicated, and achieve the effects of improving metal trapping capacity, low cost, and increasing the yield of liquid products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

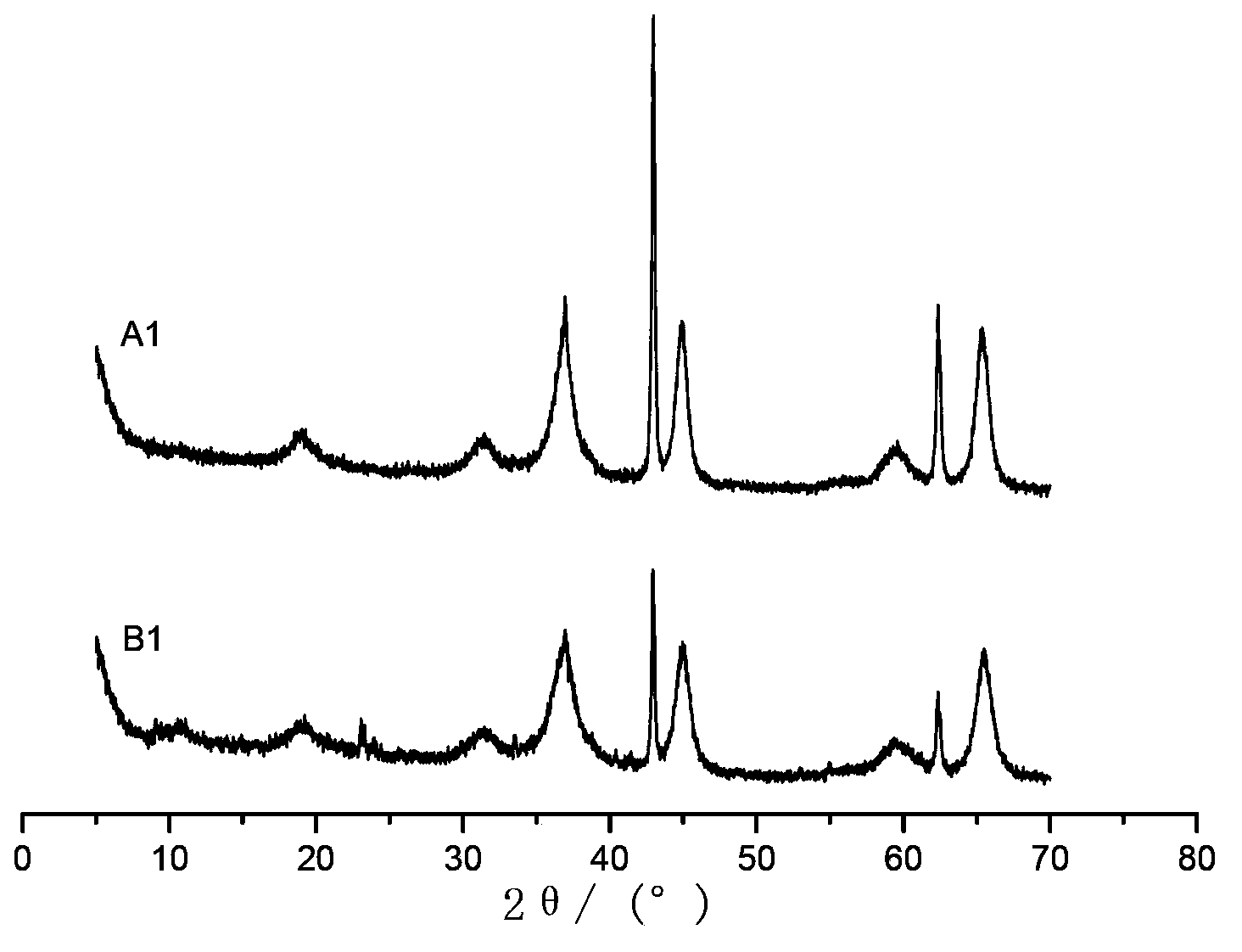

Image

Examples

Embodiment approach

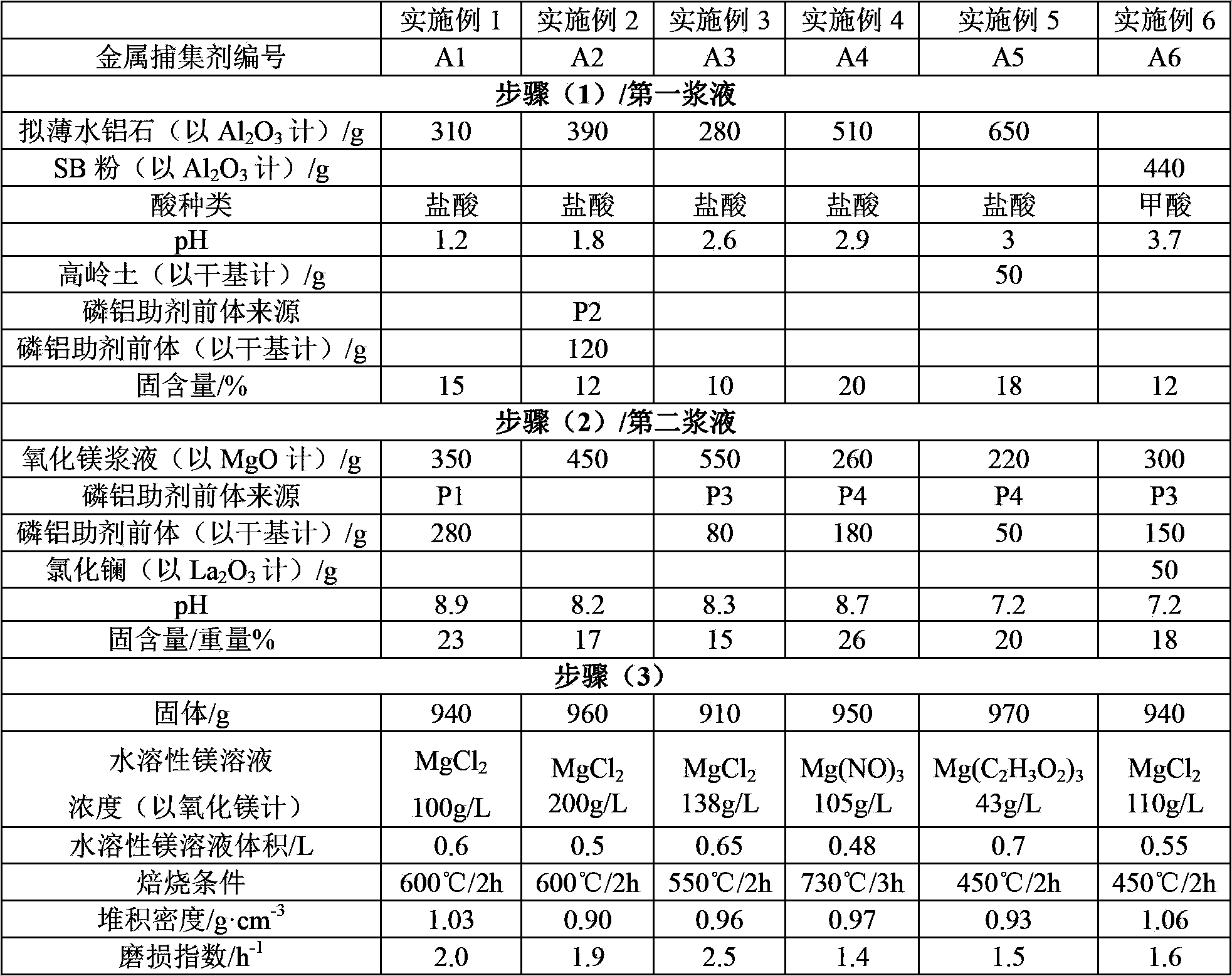

[0032]According to a preferred embodiment of the present invention, the present invention provides a kind of preparation method of metal trapping agent, and this method comprises:

[0033] (1) mixing and pulping aluminum hydroxide and / or aluminum oxide, deionized water and acid to obtain the first slurry;

[0034] (2) contacting the first slurry with magnesium hydroxide and / or magnesium oxide to obtain a second slurry, and spray drying the second slurry to obtain a solid;

[0035] (3) Contacting the solid with a water-soluble magnesium source solution, drying or not drying the contacted mixture, and roasting;

[0036] Among them, in order to introduce the phosphorus-aluminum additive into the metal scavenger of the present invention, it can be introduced in any one or more steps of the step (1), step (2) and step (3) of the present invention, that is Any one or more steps in step (1), step (2) and step (3) of the present invention can be carried out in the presence of phospho...

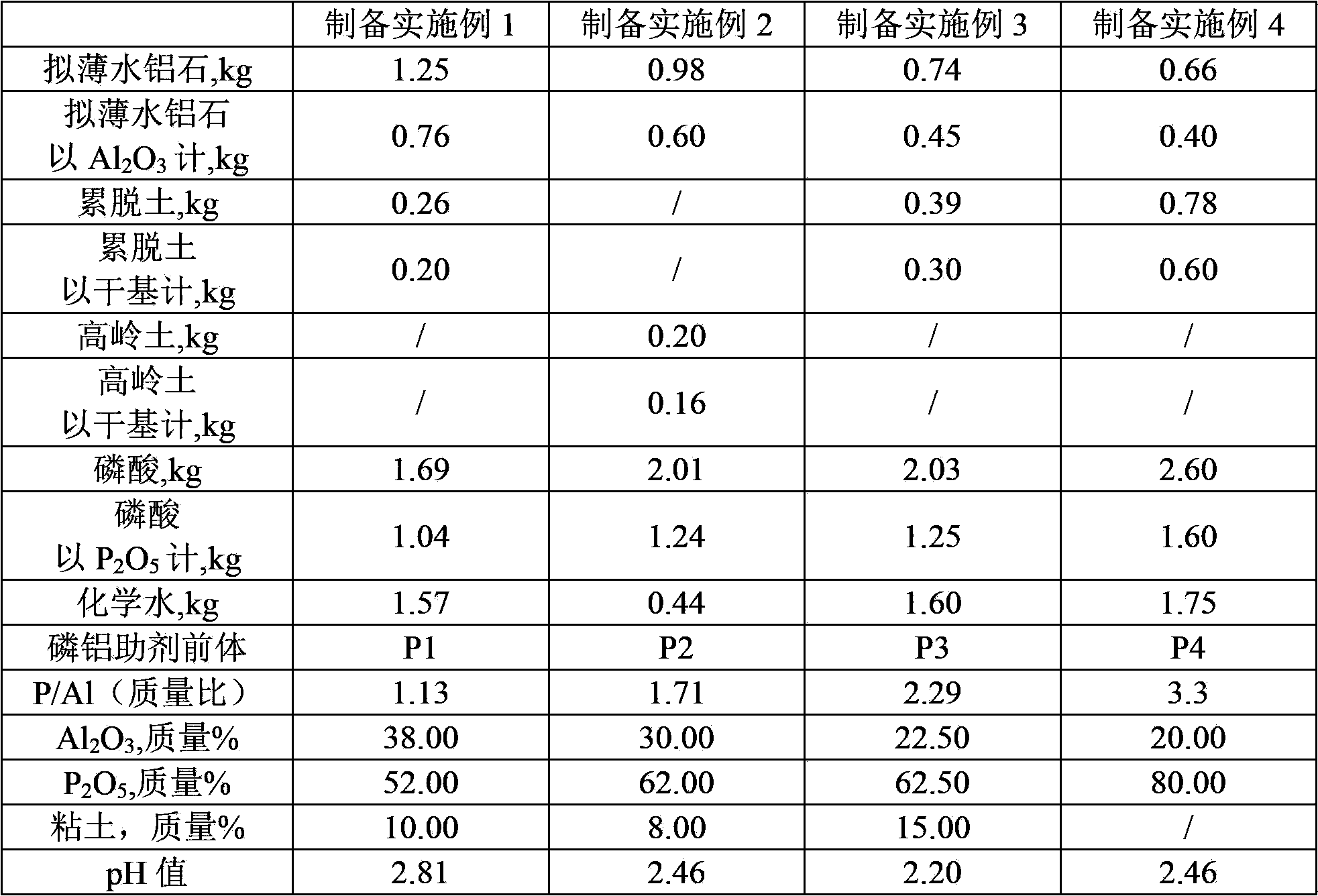

preparation Embodiment 1-4

[0079] Preparation Example 1-4 is used to prepare the phosphorus aluminum auxiliary agent precursor of the present invention

preparation Embodiment 1

[0081] 1.25 kg of pseudoboehmite (containing Al 2 o 3 0.76 kg), 0.26 kg of cumulated clay (0.2 kg on a dry basis) and 1.57 kg of decationized water were beaten for 30 minutes to obtain a slurry, and 1.69 kg of concentrated phosphoric acid was added to the slurry under stirring, and the temperature was raised to 70°C, and then Under contact for 45 minutes, the phosphorus aluminum additive precursor P1 was obtained, and the material ratio is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com