Manufactured method of transistor based on graphene field effect

A technology of field-effect transistors and graphene, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of unsatisfactory test results of graphene field-effect transistors and expensive processing methods, so as to save production costs, The effect of low power consumption and small mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

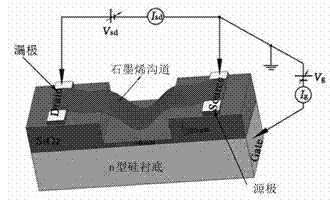

[0016] The present invention relates to graphene modification and a graphene-based compressive strain p-type field effect transistor manufacturing method, and the structure schematic diagram of the field effect transistor is as follows figure 1 shown, with a block doping concentration of 10 16 / cm 3 The n-type silicon wafer is used as the substrate, that is, the n-Si substrate, and the n-Si substrate is used as the back gate, and the back gate field effect transistor is prepared by a bottom-up processing method.

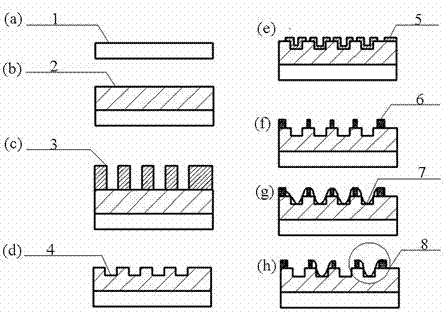

[0017] see figure 2 , figure 1 The fabrication steps of the graphene-based compressively strained P-type field effect transistor shown are as follows:

[0018] ① When the doping concentration is 10 16 / cm 3 Growth of 300 nm SiO by thermal dry oxidation on the surface of n-Si substrate 2 , control the temperature at 1000°C-1050°C for 20 minutes, such as figure 2 b.

[0019] ② To prevent SiO 2 If there are pollutants on the surface, first clean the SiO2 su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com