A limestone wet flue gas desulfurization additive and its preparation method

A technology of wet flue gas desulfurization and additives, which is applied in the chemical industry, can solve the problems of not meeting emission standards, and achieve the effects of improving spray atomization quality, reducing surface tension, and increasing dispersibility and solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

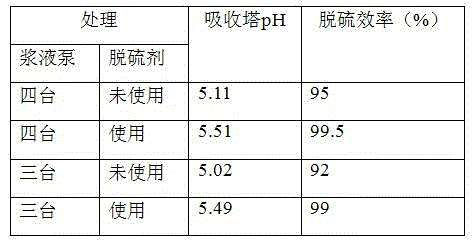

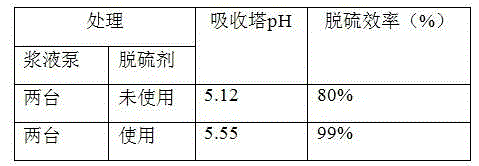

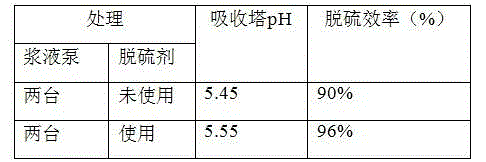

Image

Examples

Embodiment 1

[0024] The first embodiment relates to a limestone wet-process flue gas desulfurization additive, which is used to improve the desulfurization efficiency of desulfurization devices with high sulfur content, prevent system fouling, enhance the adaptability of coal types, and reduce energy consumption.

[0025] In this embodiment, the desulfurization additive includes the following raw materials by weight: 65 parts of adipic acid, 8 parts of sodium citrate, 7 parts of sodium benzoate, 3 parts of lanthanum nitrate, 7 parts of sodium acetate, 8 parts of magnesium oxide, 4 parts of magnesium sulfate share. Among them, adipic acid, sodium citrate, sodium benzoate, lanthanum nitrate, sodium acetate, magnesium oxide, and magnesium sulfate are all industrial grade chemicals; magnesium sulfate is magnesium sulfate monohydrate, sodium acetate is anhydrous sodium acetate, adipic acid, Sodium citrate, sodium benzoate, lanthanum nitrate, and magnesium oxide do not contain crystal water.

...

Embodiment 2

[0050] The second embodiment of the present invention relates to a method for making a limestone wet flue gas desulfurization additive, and the specific steps are as follows:

[0051] Accurately weigh the following raw materials in the following parts by weight: 60-70 parts of adipic acid, 5-10 parts of sodium citrate, 5-10 parts of sodium benzoate, 2-3 parts of lanthanum nitrate, 5-10 parts of sodium acetate, 5 parts of magnesium oxide ~10 parts, 3~5 parts of magnesium sulfate; Among them, adipic acid, sodium citrate, sodium benzoate, lanthanum nitrate, sodium acetate, magnesium oxide, and magnesium sulfate are all industrial grade chemicals, magnesium sulfate is magnesium sulfate monohydrate, acetic acid Sodium is anhydrous sodium acetate, and adipic acid, sodium citrate, sodium benzoate, lanthanum nitrate, and magnesium oxide do not contain crystal water; the parts of each raw material are adjusted according to the amount of coal-fired flue gas.

[0052] Add water to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com