Degassing agent with protective layer as well as preparation method thereof

A getter and protective layer technology, applied in the field of getter and its preparation, can solve the problems of easy oxidation of the getter, short life of the getter, high activation temperature of the getter, and achieve good absorption capacity and activation The effect of low temperature and lower activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

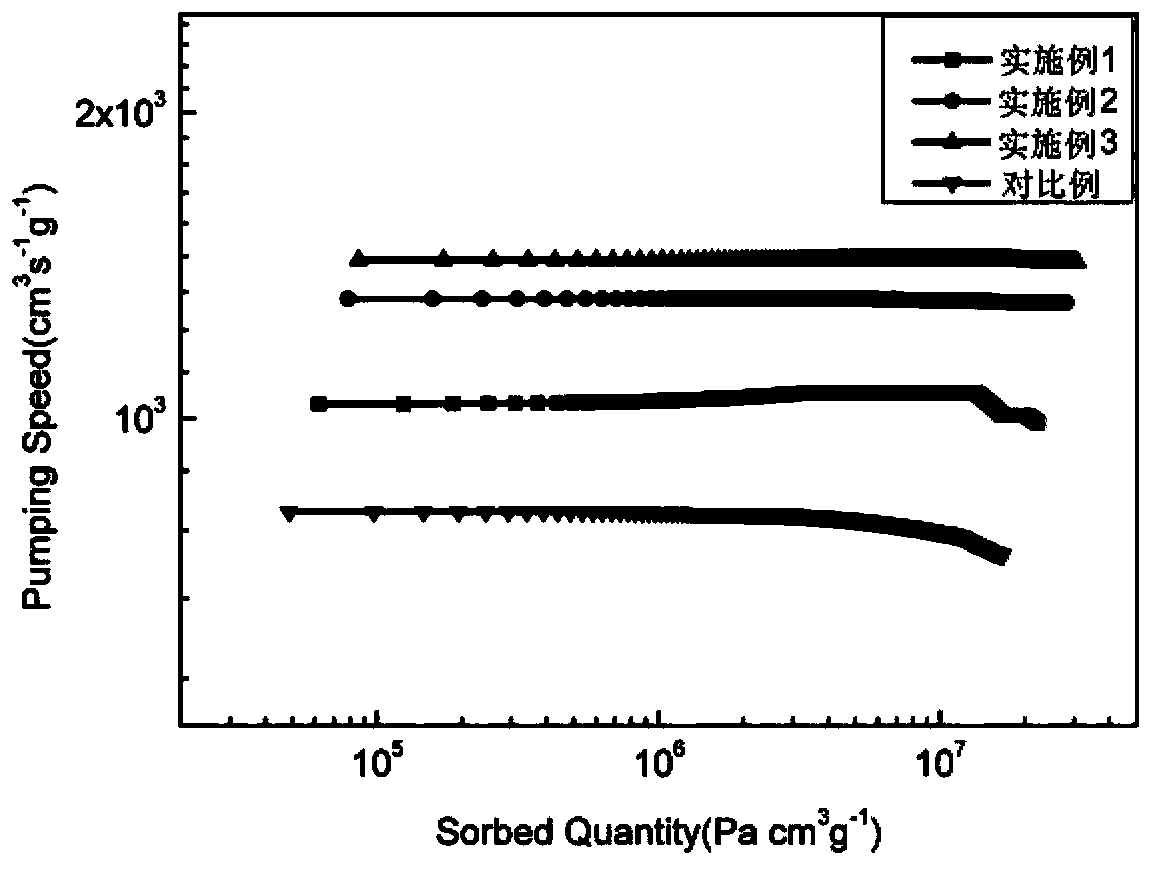

Embodiment 1

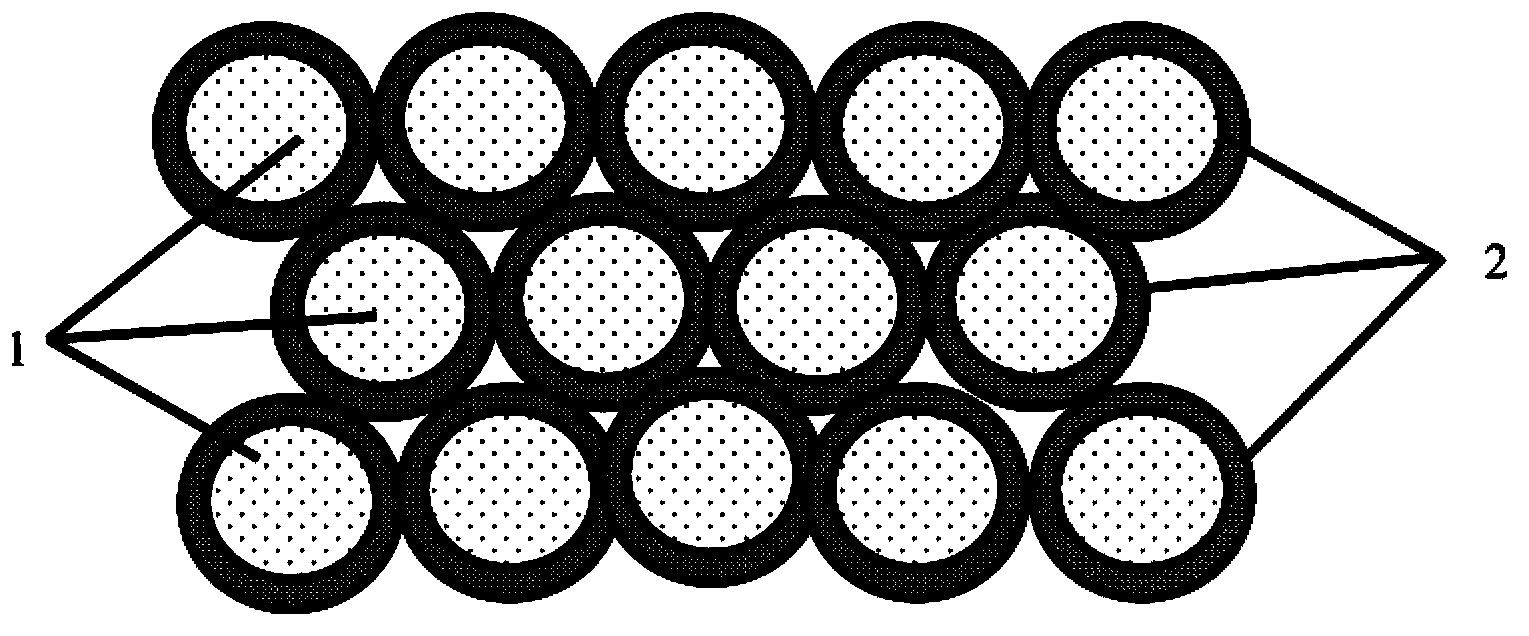

[0037] Use vacuum electric arc furnace to melt Zr-V-Fe alloy, in which the mass fraction of each component is (Zr: 80%, V: 10%, Fe: 10%), and crush it under the protection of argon until the particle diameter is 50~100μm , to get the getter particle core.

[0038] A Ni protective layer is deposited on the core of the getter particles by electroless plating. The process steps of depositing the Ni protective layer: wash the getter particles with deionized water, corrode the getter particles with HF (0.1wt.%) for 300s, and then wash with deionized water. Prepare the electroless nickel plating solution, use stainless steel as the plating tank, and use one-third of the volume of the plating tank to heat and dissolve NiCl 2 ·6H 2 O (15g / L), use another third of the water to dissolve Na 3 C 6 h 5 o 7 2H 2 O(30g / L) and H 3 BO 3 (30g / L), then NiCl 2 ·6H 2 The O solution was poured into it under stirring, clarified and filtered, and dissolved NaH with the remaining one-third ...

Embodiment 2

[0041] Use vacuum electric arc furnace to melt Zr-V-Fe alloy, in which the mass fraction of each component is (Zr: 60%, V: 35%, Fe: 5%), and crush it under the protection of argon until the particle diameter is 50~100μm , to get the getter particle core.

[0042] A Ni protective layer is deposited on the core of the getter particles by electroless plating. The process steps of depositing the Ni protective layer: wash the getter particles with deionized water, corrode the getter particles with HF (1.3wt.%) for 60s, and then wash with deionized water. Prepare the electroless nickel plating solution, use stainless steel as the plating tank, and use one-third of the volume of the plating tank to heat and dissolve NiCl 2 ·6H 2 O (25g / L), use another third of the water to dissolve Na 3 C 6 h 5 o 7 2H 2 O(50g / L) and H 3 BO 3 (36g / L), then NiCl 2 ·6H 2 The O solution was poured into it under stirring, clarified and filtered, and dissolved NaH with the remaining one-third of...

Embodiment 3

[0045] Use vacuum electric arc furnace to melt Zr-V-Fe alloy, in which the mass fraction of each component is (Zr: 79%, V: 20%, Fe: 1%), and crush it under the protection of argon until the particle diameter is 50~100μm , to get the getter particle core.

[0046] A Ni protective layer is deposited on the core of the getter particles by electroless plating. The process steps of depositing the Ni protective layer: wash the getter particles with deionized water, corrode the getter particles with HF (1.0wt.%) for 200s, and then wash with deionized water. Prepare the electroless nickel plating solution, use stainless steel as the plating tank, and use one-third of the volume of the plating tank to heat and dissolve NiCl 2 ·6H 2 O (35g / L), use another third of the water to dissolve Na 3 C 6 h 5 o 7 2H 2 O(45g / L) and H 3 BO 3 (50g / L), then NiCl 2 ·6H 2 The O solution was poured into it under stirring, clarified and filtered, and dissolved NaH with the remaining one-third o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com