Preparation method of zinc oxide/titanium dioxide nanometer composite material

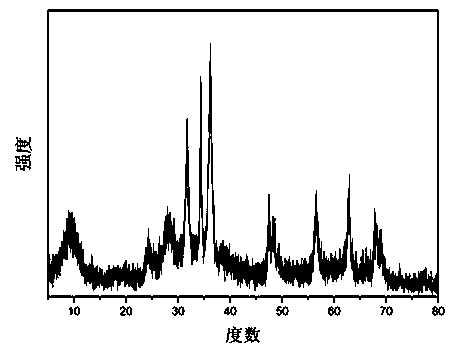

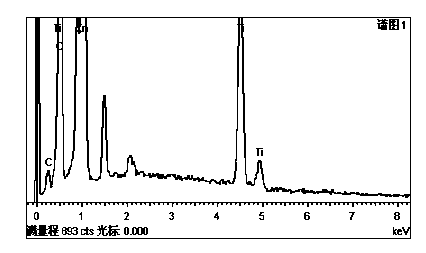

A technology of nanocomposite materials and titanium dioxide, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, bulk chemical production, etc., can solve the problems of serious agglomeration and inability to obtain dispersible nanocomposite powder materials, etc., and achieve good dispersion , good photoelectric performance and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention adopts co-precipitation-supercritical fluid drying method to prepare ZnO / TiO 2 Nanocomposite materials, the specific process steps are as follows:

[0030] (1) Configure a certain concentration of zinc ion solution (0.005mol / L);

[0031] (2) Prepare a certain concentration of alkaline solution, wherein the amount of hydroxide ion: the amount of zinc ion = 2:1;

[0032] (3) Configure a certain concentration of ethylenediamine solution, wherein the amount of ethylenediamine: the amount of zinc ions = 2:1;

[0033] (4) During the stirring process, add the alkali solution and ethylenediamine to the zinc ion solution; after stirring for a certain period of time, add a certain amount of P25 titanium dioxide powder (Degussa P25 titanium dioxide, The ratio of rutile to anatase is 3:7, the average particle size is 30 nanometers) (addition amount is 10%);

[0034] (5) Stir for a certain period of time to make it evenly mixed, then put the suspension into ...

Embodiment 2

[0038] (1) Configure a certain concentration of zinc ion solution (0.008mol / L);

[0039] (2) Prepare a certain concentration of alkaline solution, wherein the amount of hydroxide ion: the amount of zinc ion = 2:1;

[0040] (3) Configure a certain concentration of ethylenediamine solution, wherein the amount of ethylenediamine: the amount of zinc ions = 2:1;

[0041] (4) During the stirring process, add the alkali solution and ethylenediamine to the zinc ion solution; after stirring for a certain period of time, add a certain amount of P25 titanium dioxide powder (Degussa P25 titanium dioxide, The ratio of rutile to anatase is 3:7, the average particle size is 30 nanometers) (addition amount is 10%);

[0042] (5) Stir for a certain period of time to make it evenly mixed, then put the suspension into a supercritical reactor-basket for reaction, the reaction conditions are: temperature 110°C, reaction time 8h, pressure 15MPa;

[0043] (6) After the reaction, the precipitated pr...

Embodiment 3

[0045] (1) Configure a certain concentration of zinc ion solution (0.008mol / L);

[0046] (2) Prepare a certain concentration of alkaline solution, wherein the amount of hydroxide ion: the amount of zinc ion = 2:1;

[0047] (3) Configure a certain concentration of ethylenediamine solution, wherein the amount of ethylenediamine: the amount of zinc ions = 2:1;

[0048] (4) During the stirring process, add the alkali solution and ethylenediamine to the zinc ion solution; after stirring for a certain period of time, add a certain amount of P25 titanium dioxide powder (Degussa P25 titanium dioxide, The ratio of rutile to anatase is 3:7, the average particle size is 30 nanometers) (addition amount is 20%);

[0049](5) Stir for a certain period of time to make it evenly mixed, then put the suspension into a supercritical reactor-basket for reaction, the reaction conditions are: temperature 120°C, reaction time 10h, pressure 15MPa;

[0050] (6) After the reaction, the precipitated pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com