Treatment and recycling method of industrial wastewater containing a plurality of heavy metal ions

A technology for heavy metal ions and industrial wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Low-level problems, to achieve the effect of promoting circular economy and comprehensive utilization of resources, broad application prospects, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

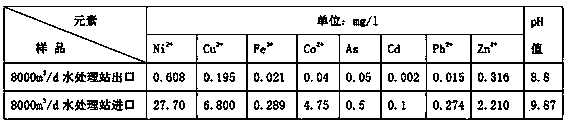

Examples

Embodiment 1

[0027] A method for the treatment and recovery of industrial wastewater containing multiple heavy metal ions, the steps of which are:

[0028] a. Oil separation and sand removal: the suspended solids and sundries in the wastewater containing various heavy metal ions are separated through the grid in the oil skimming grit chamber, and then enter the oil skimming grit chamber, and the driving of the oil skimming grit chamber is used The wastewater is skimmed on the water surface, and the sludge in the bottom is discharged by self-pressure, and the discharged sludge enters the sludge filter tank, and the wastewater after oil separation, oil skimming and desilting enters the regulating tank;

[0029] b. Water quality and quantity homogeneity adjustment: the wastewater entering the adjustment tank after oil separation, oil skimming and mud removal uses sulfuric acid and carbide slag to adjust the pH value to 8. Since the wastewater is generally acidic, calcium carbide slag is added ...

Embodiment 2

[0037] A method for the treatment and recovery of industrial wastewater containing multiple heavy metal ions, the steps of which are:

[0038] a. Oil separation and sand removal: the suspended solids and sundries in the wastewater containing various heavy metal ions are separated through the grid in the oil skimming grit chamber, and then enter the oil skimming grit chamber, and the driving of the oil skimming grit chamber is used The wastewater is skimmed on the water surface, and the sludge in the bottom is discharged by self-pressure, and the discharged sludge enters the sludge filter tank, and the wastewater after oil separation, oil skimming and desilting enters the regulating tank;

[0039] b. Adjustment of water quality and quantity homogeneity: the wastewater entering the adjustment tank after oil separation, oil skimming and desilting is adjusted to a pH value of 9 with hydrochloric acid and carbide slag. Since the wastewater is generally acidic, calcium carbide slag i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com