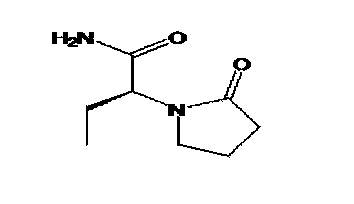

Preparation method of levetiracetam

A technology of ethyl and ethanol, applied in the direction of organic chemistry, can solve the problems of 4-chlorobutyryl chloride instability, strong base racemization, easy hydrolysis, etc., and achieve stable yield, small amount of solvent, and low solvent toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

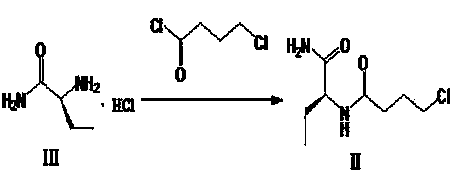

[0027] Step 1): Preparation of (S)-N-[1(aminocarbonyl)propyl]-4-chlorobutanamide (II)

[0028] Add (s)-2-aminobutyramide hydrochloride 2.5Kg (18.04mol), potassium carbonate 6220g (45.10mol), ethanol 30L into a 50L reactor and stir overnight, then add 4-chlorobutyryl chloride 3050g (21.65mol) dropwise , Stir for 30 minutes after dropping, TLC detection (developer: ethyl acetate / acetone=3 / 1, RfIII=0.1, RfII=0.7), filter after reaction, concentrate the filtrate to dryness under reduced pressure at 45°C, add acetic acid to the residue Ethyl ester / petroleum ether (1 / 4) 20L was beaten for 1-2 hours, filtered, and the solid was air-dried at 35°C overnight to obtain 2920g of white solid (II), with a yield of >74.2%.

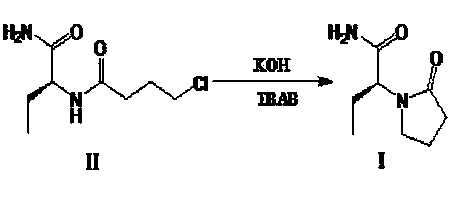

[0029] Step 2: Preparation of (S)-α-ethyl-2-oxo-1-pyrrolidineacetamide (levetiracetam) (I)

[0030] Add (S)-N-[1(aminocarbonyl)propyl]-4-chlorobutanamide (II) 5760g (27.9mol), dichloromethane 45L, tetrabutylammonium bromide 463g (1.4 mol), stir and mix, lower the tem...

Embodiment 2

[0034] The key intermediate is (S)-N-[1(aminocarbonyl)propyl]-4-chlorobutanamide (II) quality control method:

[0035] The TLC method detected basically a single spot, and the HPLC detection purity was greater than 95%.

[0036] TLC detection conditions: developer: ethyl acetate / acetone; volume ratio = 1:3; color development method: phosphomolybdic acid spraying, high temperature color development.

[0037] HPLC detection conditions:

[0038] Instrument: Shimadzu 20A series high performance liquid chromatography

[0039] Chromatographic column: Ymc-pack ODS-AQ column (4.6′150mm, 3μm)

[0040] Buffer salt: 0.26g potassium dihydrogen phosphate, add water to 1000ml, adjust pH to 5.50 with 2% potassium hydroxide

[0041] Mobile phase A: buffer salt-acetonitrile=19:1

[0042] Mobile Phase B: Acetonitrile

[0043] Flow rate: 0.9ml / min;

[0044] Injection volume: 10μl

[0045] Column temperature: room temperature

[0046] Detection wavelength: 205nm

[0047] Elution gradient...

Embodiment 3

[0050] Step 1): Preparation of (S)-N-[1(aminocarbonyl)propyl]-4-chlorobutanamide (II)

[0051] Add (s)-2-aminobutyramide hydrochloride 2.5Kg (18.04mol), potassium carbonate 6220g (45.10mol), ethanol 50L into a 50L reactor and stir overnight, then add 4-chlorobutyryl chloride 3050g (21.65mol) dropwise , Stir for 30 minutes after dropping, TLC detection (developer: ethyl acetate / acetone=3 / 1, RfIII=0.1, RfII=0.7), filter after reaction, concentrate the filtrate to dryness under reduced pressure at 45°C, add acetic acid to the residue Ethyl ester / petroleum ether (1 / 4) 20L was beaten for 1-2 hours, filtered, and the solid was air-dried at 35°C overnight to obtain 2920g of white solid (II), with a yield of >74.2%.

[0052] Step 2: Preparation of (S)-α-ethyl-2-oxo-1-pyrrolidineacetamide (levetiracetam) (I)

[0053]Add (S)-N-[1(aminocarbonyl)propyl]-4-chlorobutanamide (II) 5760g (27.9mol), dichloromethane 45L, tetrabutylammonium bromide 463g (1.4 mol), stir and mix, lower the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com