Process for preparing gasoline through synthesis gas

A technology for synthesis gas and gasoline, applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of catalyst sintering deactivation, catalyst deactivation, shortening of catalyst life, etc., to improve energy utilization, reduce energy consumption and The effect of increased cost and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

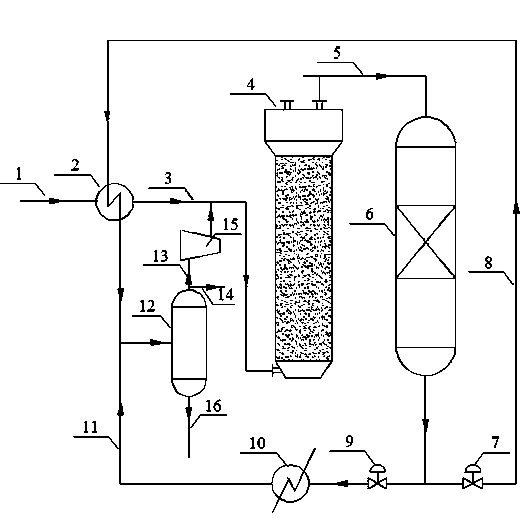

[0032] Step (1) Synthesis gas 1 is mainly produced by coal gasification or natural gas cracking, with a hydrogen-to-carbon volume ratio of 2, pressurized to 2.5MPa, and heat-exchanges with the tail gas 8 of the preheated synthesis gas through the heat exchanger 2, and the preheated After heating, it enters the slurry bed reactor 4.

[0033] Step (2) Slurry bed reactor 2 adopts air flow bubbling suspension slurry bed reactor, uses liquid paraffin as inert liquid phase heat carrier, reaction temperature is 240°C, reaction pressure is 2.5MPa, and space velocity is 6000ml·g -1 h -1, the syngas is dehydrated into dimethyl ether by a bifunctional catalyst (a bifunctional catalyst LP201+TH16 developed by Tsinghua University (LP201 mass content 67%, TH16 mass content 33%)) in the reactor, of which the single-pass conversion rate of CO is 65% .

[0034] Step (3) The tail gas 5 after the slurry bed reaction directly enters the fixed bed reactor 6, and the fixed bed reactor 6 is equipp...

Embodiment 2

[0039] Step (1) Synthesis gas 1 is mainly produced by coal gasification or natural gas cracking, with a hydrogen-to-carbon volume ratio of 3, pressurized to 2.0 MPa, and exchanges heat with the tail gas 8 of the preheated synthesis gas through the heat exchanger 2. After heating, it enters the slurry bed reactor 4.

[0040] Steps (3), (4), (5) are the same as in Example 1

[0041] Step (2) Slurry bed reactor 4 adopts air flow bubbling to suspend slurry bed reactor, uses liquid paraffin as inert liquid phase heat carrier, and uses n-hexane as supercritical medium, reaction temperature 250°C, reaction pressure 3MPa, space velocity 5000ml·g -1 h -1 , the syngas is dehydrated into dimethyl ether by a bifunctional catalyst (a bifunctional catalyst LP201+TH16 developed by Tsinghua University (LP201 mass content 67%, TH16 mass content 33%)) in the reactor, in which the single-pass conversion rate of CO is 65% , H 2 The single-pass conversion rate is 62%.

[0042] The obtained ga...

Embodiment 3

[0044] Step (1) Synthesis gas 1 is mainly produced by coal gasification or natural gas cracking, with a hydrogen-to-carbon volume ratio of 2.5, pressurized to 4.0 MPa, and exchanges heat with the tail gas 8 of the preheated synthesis gas through the heat exchanger 2. After heating, it enters the slurry bed reactor 4.

[0045] Steps (3), (4), (5) are the same as in Example 1

[0046] Step (2) The slurry bed reactor 4 adopts a mechanically stirred tank type slurry bed, uses liquid paraffin as an inert liquid phase heat carrier, and uses n-hexane as a supercritical medium, the reaction temperature is 230°C, the reaction pressure is 4MPa, and the space velocity is 3000ml· g -1 h -1 , the synthesis gas passes through the bifunctional catalyst in the reactor (the bifunctional catalyst CN1176742C developed by Nanhua Group, the composition of the catalyst mainly includes metal oxides and acidic components, and the suitable weight content of metal oxides: CuO is 30% , ZnO is 20%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com