Preparation method and applications of freeze-dried powder of acetic acid bacteria

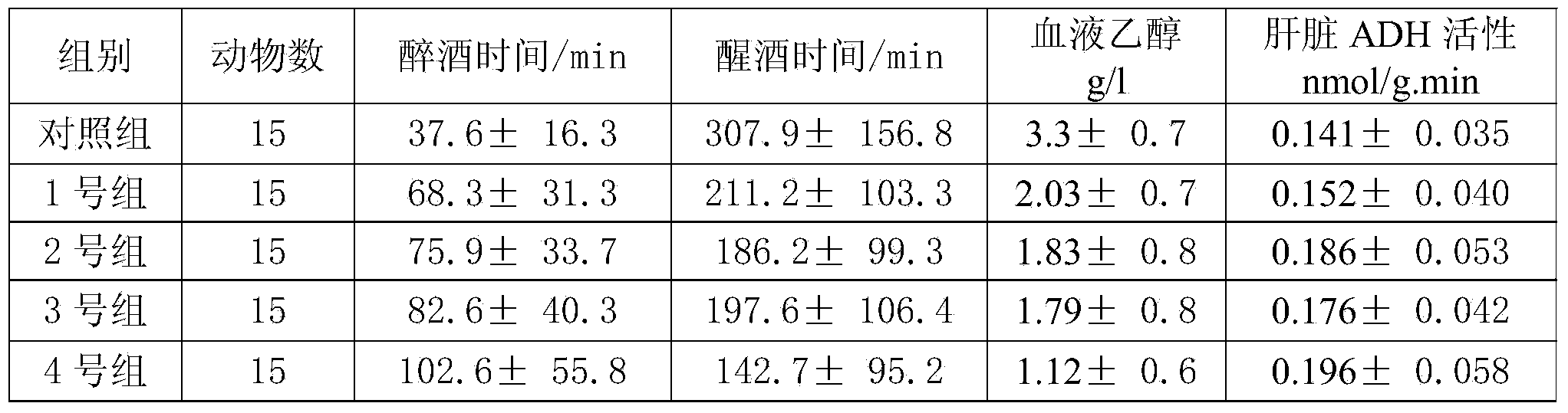

A technology for freeze-dried bacteria powder and acetic acid bacteria strain, which is applied in the field of preparation of acetic acid bacteria freeze-dried bacteria powder, can solve the problems of too much lightening of liver burden, slow reaction speed, unsatisfactory effect and the like, achieves protection of the liver, reduces The speed of metabolism, the effect of good hangover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

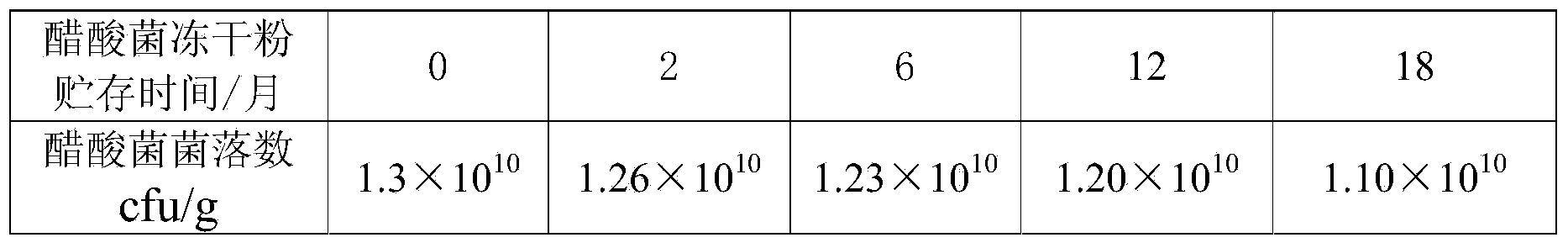

[0030] Preparation of freeze-dried powder of Acetobacter pasteurianus and production of hangover tablet

[0031] 1) Inoculate the Acetobacter pasteurii strain into the liquid medium first, and cultivate it at 28°C for 10 hours to obtain the first-grade strain, and the Acetobacter pasteurii strain accounts for 0.1% of the mass of the liquid medium; The composition and mass percentage of the liquid medium are glucose 2%, yeast extract 2%, MgSO 4 .7H 2 O0.05%, KH 2 PO 4 0.05%, absolute ethanol 4%, and the rest is water; during the preparation of the liquid medium, first mix the components except absolute ethanol evenly, sterilize at 121°C for 15 minutes, then add absolute ethanol, and the liquid culture base pH = 6.0;

[0032] 2) Insert the primary strain into the fermentation medium and culture it at 28°C for 20 hours. At the same time, add 5% sodium hydroxide aqueous solution during the fermentation process to maintain the pH of the fermentation medium = 5.0-6.5 to obtain a...

Embodiment 2

[0039] Preparation of freeze-dried powder of Acetobacter oxydans and production of hangover tablet

[0040] 1) Inoculate the strain of Acetobacter oxydans into the liquid medium first, and culture it at 30°C for 15 hours to obtain the first-grade strain, and the strain of Acetobacter oxidans accounts for 0.05% of the mass of the liquid medium; The composition and mass percentage of the liquid medium are glucose 2.5%, yeast extract 2.5%, MgSO 4 .7H 2 O0.01%, KH 2 PO 4 0.1%, absolute ethanol 7%, and the rest is water; in the process of liquid medium preparation, firstly mix the components except absolute ethanol, sterilize at 121°C for 15 minutes, then add absolute ethanol, the liquid culture base pH = 6.0;

[0041] 2) Insert the primary strain into the fermentation medium and culture it at 30°C for 22 hours. At the same time, add 10% sodium hydroxide aqueous solution during the fermentation process to maintain the pH of the fermentation medium = 5.0-6.5 to obtain a fermenta...

Embodiment 3

[0048] Preparation of freeze-dried powder of Acetobacter hansenii and production of hangover drink

[0049] 1) Put the Acetobacter hansenii strains into the liquid medium first, and cultivate them at 30°C for 30 hours to obtain the first-grade strains, and the Acetobacter hansenii strains account for 0.01% of the liquid medium mass %; The composition and mass percent of the liquid medium are glucose 1%, yeast extract 1%, MgSO 4 .7H 2 O0.01%, KH 2 PO 4 0.3%, absolute ethanol 10%, and the rest is water; in the process of liquid medium preparation, first mix the components except absolute ethanol evenly, sterilize at 121°C for 15 minutes, then add absolute ethanol, the liquid culture base pH = 6.0;

[0050] 2) Insert the primary strain into the fermentation medium and culture it at 33°C for 30 hours. At the same time, add 25% sodium hydroxide aqueous solution during the fermentation process to maintain the pH of the fermentation medium at 5.0-6.5 to obtain a fermentation mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com