A kind of preparation method of polymer ultrafiltration membrane

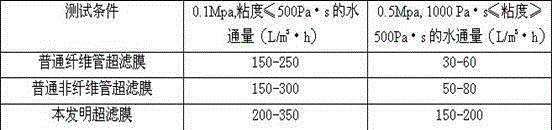

An ultrafiltration membrane and polymer technology, applied in the field of membrane separation, can solve the problems of large liquid flow resistance, large pressure loss, short life, etc., and achieve high retention rate, low flow resistance, and small pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

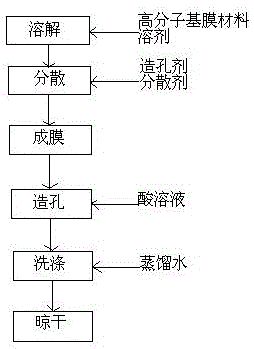

Method used

Image

Examples

Embodiment 1

[0029] 1) Dissolving 20 parts by weight of polysulfone with 70 parts by weight of dimethylformamide while stirring at room temperature, the stirring speed is 50r / min, so that the polymer basement membrane material is completely dissolved in the solvent to form a basement membrane liquid;

[0030] 2) Add 2 parts by weight of calcium carbonate and 1 part by weight of triethylhexyl phosphoric acid to the basement membrane liquid obtained in step 1), oscillate and disperse for 10 minutes with an ultrasonic generator, and perform vacuum defoaming treatment after the dispersion is uniform to form a casting film liquid;

[0031] 3) Cast the film casting liquid obtained in step 2) on a glass plate, dry it naturally for 40 seconds, immerse it in a gel bath, and solidify it into a film through the gel;

[0032] 4) Immerse the membrane obtained in step 3) into hydrochloric acid solution, and dissolve it with ultrasonic vibration for 20 minutes, take it out, wash it with distilled water, ...

Embodiment 2

[0034] 1) 30 parts by weight of polyvinyl chloride are dissolved with 60 parts by weight of dimethyl acetyl at room temperature while stirring, and the stirring speed is 80r / min, so that the polymer base film material is completely dissolved in the solvent to form a base film liquid;

[0035] 2) Add 5 parts by weight of magnesium carbonate and 3 parts by weight of sodium lauryl sulfate to the basement membrane liquid obtained in step 1), oscillate and disperse for 20 minutes with an ultrasonic generator, and perform vacuum defoaming treatment after the dispersion is uniform to form a casting Membrane fluid;

[0036] 3) Cast the film casting liquid obtained in step 2) on a glass plate, dry it naturally for 60 seconds, immerse it in a gel bath, and solidify it into a film through the gel;

[0037] 4) Immerse the membrane obtained in step 3) into the nitric acid solution, and dissolve it with ultrasonic vibration for 20 minutes, take it out, wash it with distilled water, and dry ...

Embodiment 3

[0039] 1) Dissolving 20 parts by weight of polyacrylonitrile with 60 parts by weight of N-methylpyrrolidone while stirring at room temperature, the stirring speed is 50r / min, so that the polymer base film material is completely dissolved in the solvent to form a base film liquid;

[0040] 2) Add 5 parts by weight of barium carbonate and 3 parts by weight of methyl amyl alcohol to the basement film liquid obtained in step 1), oscillate and disperse for 20 minutes with an ultrasonic generator, and perform vacuum defoaming treatment after the dispersion is uniform to form a casting film liquid ;

[0041] 3) Cast the film casting liquid obtained in step 2) on a glass plate, dry it naturally for 40 seconds, immerse it in a gel bath, and solidify it into a film through the gel;

[0042] 4) Immerse the membrane obtained in step 3) into hydrochloric acid solution, and dissolve it with ultrasonic vibration for 20 minutes, take it out, wash it with distilled water, and dry it to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com