Catalyst, preparation method and application thereof

A catalyst and solvent technology, applied in the field of preparation of the catalyst, can solve the problems of unfavorable catalyst life, high catalyst reaction temperature, and difficulty in obtaining a catalyst with mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] 2. The preparation method of heteropolyacid salt catalyst of the present invention

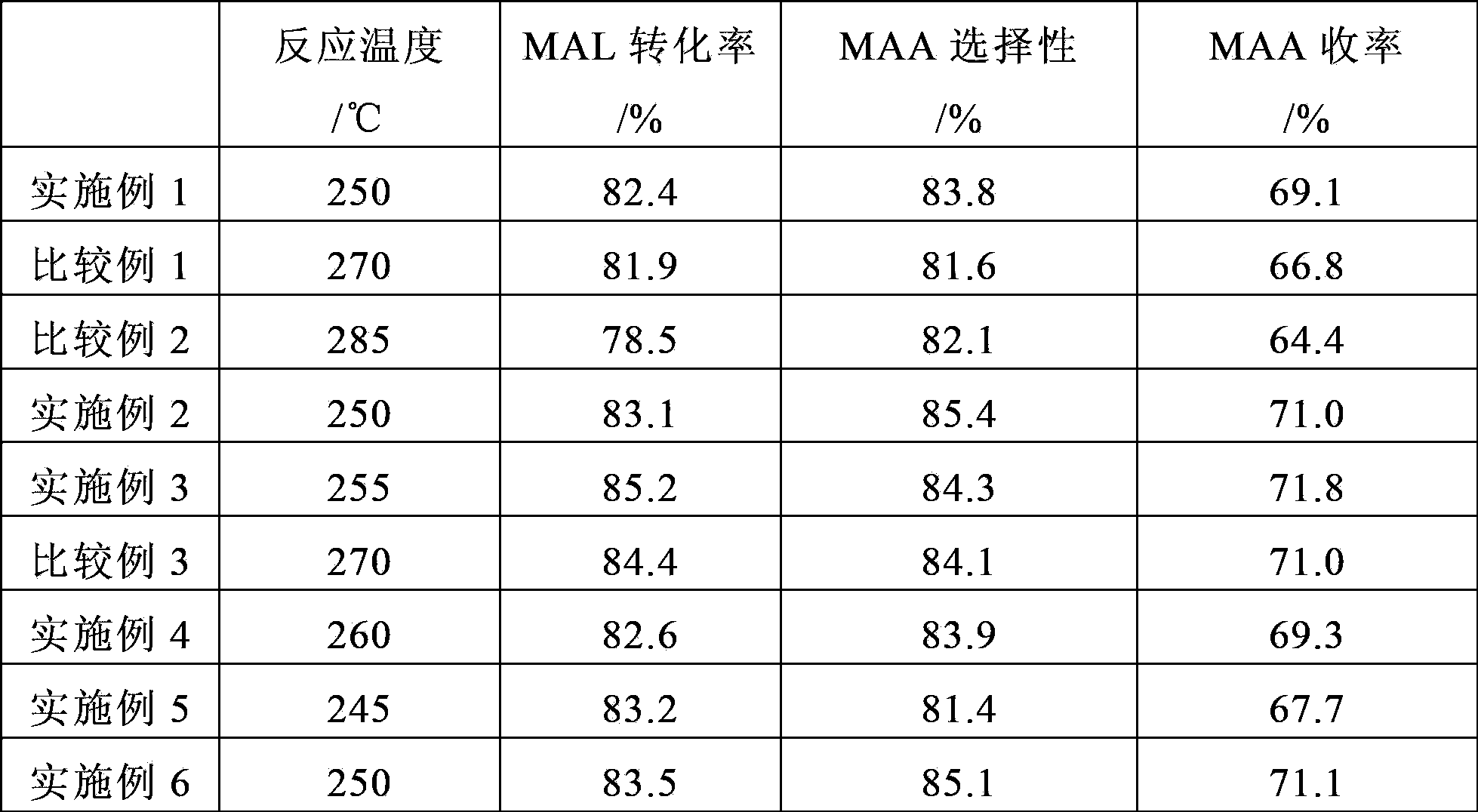

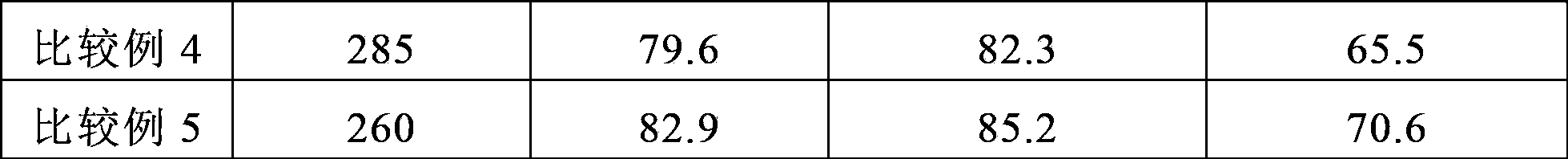

[0059] The inventors of the present invention have found that if the above-mentioned catalyst is prepared by a low-temperature mixing method, the prepared catalyst will have improved methacrolein conversion, methacrylic acid selectivity and methacrylic acid yield. The present invention has been accomplished on the basis of this discovery.

[0060] Therefore, the above-mentioned catalyst of the present invention is prepared by the following method: the compounds of the corresponding component elements are dissolved, respectively used as liquid A, liquid B and liquid C, and the three solutions are mixed at -5 to 10°C to prepare The suspension and dispersion slurry of the catalyst precursor containing all the above catalyst components is dried, and the dried catalyst precursor is pre-calcined, added with a dilute heat conducting agent to form, and roasted to obtain a finished catalyst.

...

Embodiment 1

[0091] 1. Catalyst Preparation

[0092] 300 grams of ammonium paramolybdate, 9.9 grams of ammonium metavanadate and 24.2 grams of phosphoric acid were dissolved in 400 grams of distilled water to obtain solution A; 28.5 grams of potassium nitrate and 10.4 grams of copper nitrate were dissolved in 100 grams of distilled water to obtain a solution B; 2.9 grams of ferric nitrate was dissolved in 5 grams of distilled water to obtain solution C.

[0093] Cool liquid A to 4°C, mix liquid B with liquid A for 10 minutes under stirring condition, and mix liquid C with liquid AB after stirring for 10 minutes to obtain ABC mixed slurry, continue stirring at 4°C for 120 minutes , to obtain a slurry containing the catalyst precursor.

[0094] The slurry was dried at 150°C for 24 hours to obtain a solid powder. Roast at 250°C for 3 hours in an air atmosphere, mix 85g of solid powder with 15g of silicon carbide, add 2g of graphite and appropriate amount of distilled water, extrude, and make ...

Embodiment 2

[0112] 1. Catalyst Preparation

[0113] 300 grams of ammonium paramolybdate, 9.9 grams of ammonium metavanadate and 24.2 grams of phosphoric acid were dissolved in 400 grams of distilled water to obtain solution A; 28.5 grams of potassium nitrate and 10.4 grams of copper nitrate were dissolved in 100 grams of distilled water to obtain a solution B; 2.9 grams of ferric nitrate was dissolved in 5 grams of distilled water to obtain solution C.

[0114] Cool liquid A to 4°C, mix liquid B with liquid A under stirring condition for 10 minutes, mix liquid C with AB mixed liquid after stirring for 10 minutes, obtain ABC mixed slurry, continue stirring at 4°C for 300 minutes , to obtain a slurry containing the catalyst precursor.

[0115] The slurry was dried at 150°C for 24 hours to obtain a solid powder. Roast at 250°C for 3 hours in an air atmosphere, mix 85g of solid powder with 15g of silicon carbide, add 2g of graphite and appropriate amount of distilled water, extrude, and mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com