Morpholine ionic liquid, and preparation method and application thereof

A technology of ionic liquids and morpholines, which is applied in the preparation of sulfonamides, organic chemistry, hybrid capacitor electrolytes, etc., can solve the problems of narrowing electrochemical window, rising melting point, and decreasing stability of ionic liquids, and achieves decomposition voltage High, good thermal stability, high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

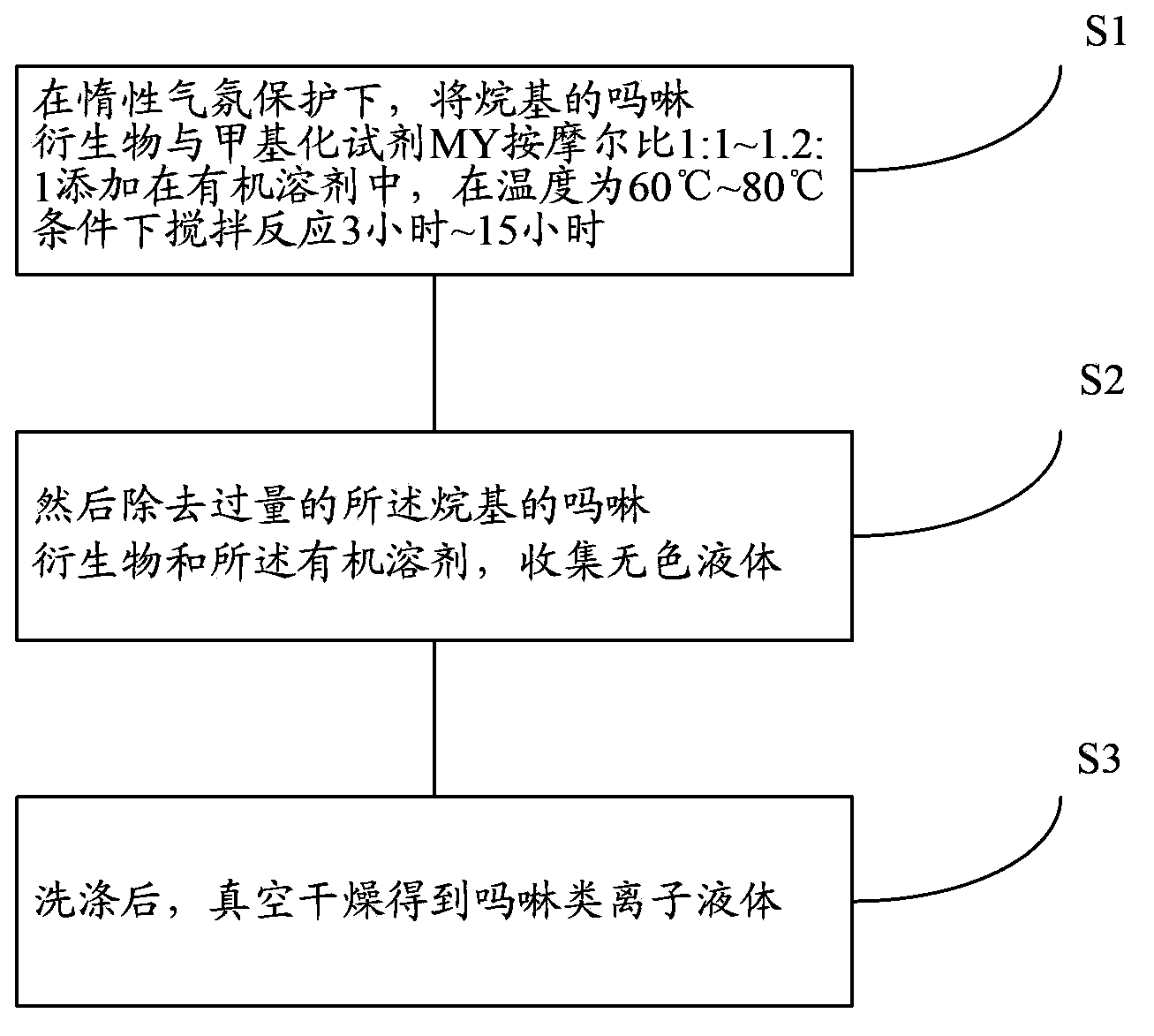

[0038] A preparation method of the above-mentioned morpholine ionic liquid, the preparation process is as follows:

[0039]

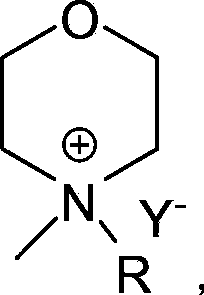

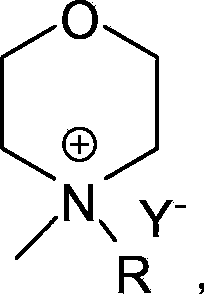

[0040] Where MY is N-methyl-bis(trifluoromethanesulfonyl)amine or N-methyl-bis(fluorosulfonyl)amine; R is an alkyl group with 2 to 6 carbon atoms, Y - for (CF 3 SO 2 ) 2 N - or (FSO 2 ) 2 N - .

[0041] Specifically include the following steps:

[0042] Step S1: under the protection of an inert atmosphere, the alkylmorpholine derivative and the methylation reagent MY are added to the organic solvent in a molar ratio of 1:1 to 1.2:1, the mass of the organic solvent and the alkylmorpholine derivative The ratio is 0.8:1~1.4:1, and the reaction is stirred for 3 hours~15 hours at a temperature of 60°C~80°C.

[0043] Wherein, the alkylmorpholine derivatives are ethylmorpholine, propylmorpholine, butylmorpholine, pentylmorpholine or hexylmorpholine.

[0044] Wherein, the methylating agent MY is N-methyl-bis(trifluoromethanesulfonyl)amide or N-meth...

Embodiment 1

[0068] Add 101.4g chloroform, (126.7g, 1.1mol) ethyl morpholine, (295g, 1.0mol) N-methyl-bis(trifluoromethanesulfonyl)amine respectively in a 500mL flask, and raise the temperature under a nitrogen atmosphere to 70°C and stirred for 10 hours. Stand to cool, carry out vacuum distillation at a temperature of 150°C and a pressure of 3.0Pa to remove excess reactants, collect the colorless liquid and wash it three times with 50ml of ethyl acetate, then at a temperature of 80°C, vacuum Vacuum drying was carried out under the condition of 0.01MPa to obtain colorless liquid N-ethyl-N-methylmorpholine bis(trifluoromethanesulfonyl)imide salt with a yield of 93%.

[0069] Its hydrogen spectrum data are as follows:

[0070] 1 H NMR (CDCl 3 ,400MHz,ppm):3.84(m,2H),3.73(m,2H),3.62(m,2H),3.38(m,2H),3.32(s,3H),3.29(m,2H),1.26( t,3H).

[0071] Under the protection of an inert atmosphere, take out 10g of N-ethyl-N-methylmorpholine bis(trifluoromethanesulfonyl)imide salt, then add 30g of ac...

Embodiment 2

[0073] Add 129g of dichloromethane, (129.2g, 1.0mol) propyl morpholine, (195g, 1.0mol) N-methyl-bis(fluorosulfonyl)amine respectively in a 500mL flask, and heat up to 60°C, stirred for 3 hours. Stand to cool, carry out vacuum distillation at a temperature of 120°C and a pressure of 0.1Pa to remove excess reactants, collect the colorless liquid and wash it three times with 50ml of methyl tert-butyl ether, and then wash it at a temperature of 70°C , vacuum-dried at a vacuum of 0.01 MPa to obtain a colorless liquid N-propyl-N-methylmorpholine bis(fluorosulfonyl)imide salt with a yield of 91%.

[0074] Its hydrogen spectrum data are as follows:

[0075] 1 H NMR (CDCl 3 ,400MHz,ppm):3.83(m,2H),3.74(m,2H),3.62(m,2H),3.37(m,2H),3.32(s,3H),3.27(m,2H),1.78( m,2H),0.96(t,3H).

[0076] in N 2 (or Ar 2 ) under the protection of atmosphere, take out 10g of N-propyl-N-methylmorpholine bis(fluorosulfonyl)imide salt, then add 50g of propylene carbonate to it, and stir and mix it evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com