Efficient production method of biological polysaccharide gellan gum

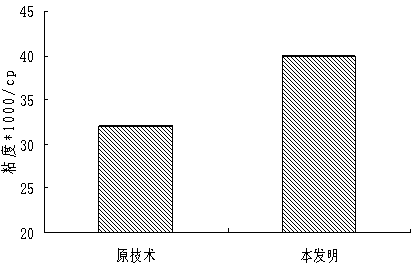

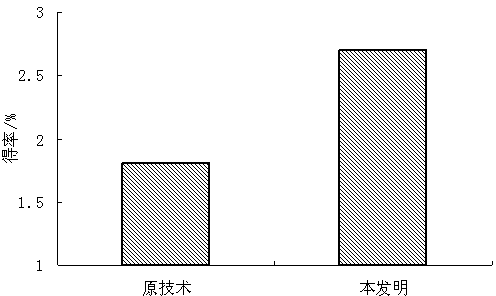

A biological polysaccharide and production method technology, applied in the field of microbial fermentation, can solve the problems of slow direct utilization of nitrogen source of beans, inability to obtain high-yield gellan gum, high production cost of gellan gum, etc., to achieve easy control and improve utilization rate , The effect of unit capacity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

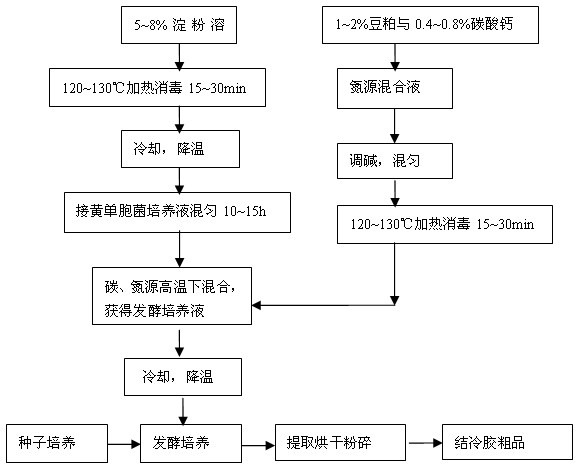

Method used

Image

Examples

Embodiment 1

[0035] Embodiments 1 to 4 are specific implementations of a high-efficiency production method of biopolysaccharide gellan gum of the present invention, wherein embodiment 1 is the best embodiment.

[0036] Example 1

[0037] In the fermentation culture, the fermentation broth is configured in the following steps:

[0038] Configure carbon source solution: in a 50-square fermenter, use cornstarch and tap water to configure a starch solution with a mass percentage of 8%;

[0039] Sterilization of carbon source solution: heat and sterilize the starch solution at 121°C for 30 minutes, and cool down to 28~33°C after the end;

[0040] Carbon source solution inoculation: add Xanthomonas culture solution to the starch solution, the volume ratio of Xanthomonas culture solution to starch solution is 4% (v / v), keep the temperature at 28~33°C, pass sterile air, Mix for 15 hours to obtain starch treatment solution;

[0041] Prepare nitrogen source mixed solution: mix soybean meal, cal...

Embodiment 2

[0051] In the fermentation culture, the fermentation broth is configured in the following steps:

[0052] Configure carbon source solution: in a 50-square fermenter, use starch and groundwater to configure a starch solution with a mass percentage of 8%;

[0053] Sterilization of carbon source solution: heat and sterilize the starch solution at 130°C for 15 minutes, and cool down to 28~33°C after the end;

[0054] Carbon source solution inoculation: add Xanthomonas culture solution to the starch solution, the volume ratio of Xanthomonas culture solution to starch solution is 4% (v / v), keep the temperature at 28~33°C, pass sterile air, Mix for 15 hours to obtain starch treatment solution;

[0055] Configure the nitrogen source mixed solution: mix soybean meal, calcium carbonate and groundwater in a temporary storage tank to prepare the nitrogen source mixed solution. The nitrogen source mixed solution contains 2% soybean meal and 0.8% calcium carbonate in terms of mass percenta...

Embodiment 3

[0064] In the fermentation culture, the fermentation broth is configured in the following steps:

[0065] Configure carbon source solution: in a 50-square fermenter, use starch and groundwater to configure a starch solution with a mass percentage of 6%;

[0066] Sterilization of carbon source solution: heat and sterilize the starch solution at 121°C for 30 minutes, and cool down to 28~33°C after the end;

[0067] Carbon source solution inoculation: add Xanthomonas culture solution to the starch solution, the volume ratio of Xanthomonas culture solution to starch solution is 4% (v / v), keep the temperature at 28~33°C, pass sterile air, Mix for 15 hours to obtain starch treatment solution;

[0068] Configure the nitrogen source mixed solution: mix soybean meal, calcium carbonate and groundwater in a temporary storage tank to prepare the nitrogen source mixed solution. The nitrogen source mixed solution contains 2% soybean meal and 0.8% calcium carbonate in terms of mass percenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com