A method for the preparation of monolayer g-c3n4 nanomaterials with single-atom thickness

A single-atom-thick, nano-material technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve unobtained problems, achieve cheap raw materials, simple preparation process, and improve photocatalytic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

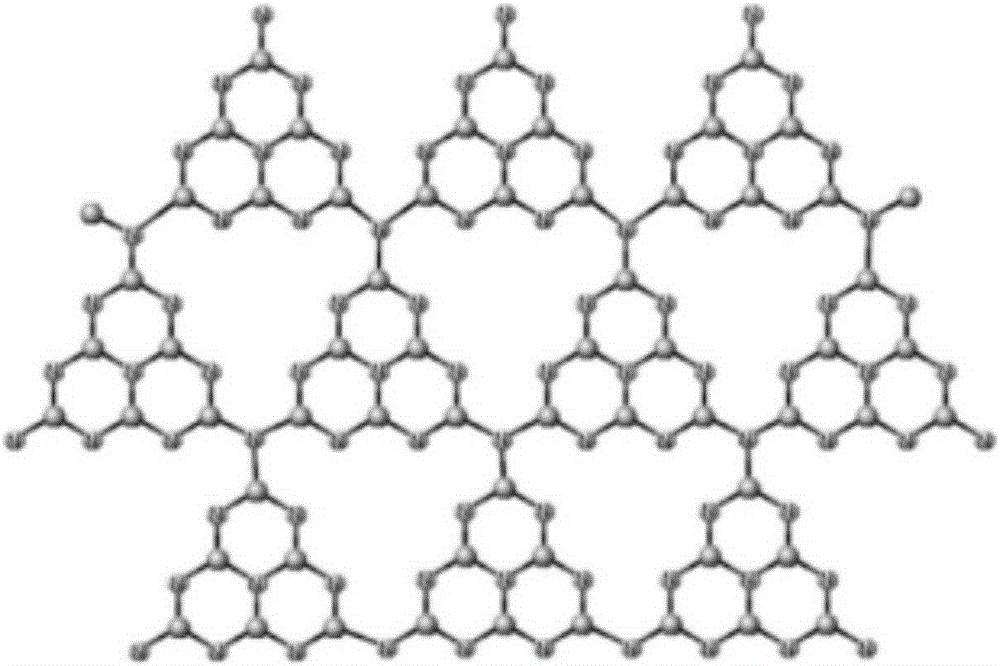

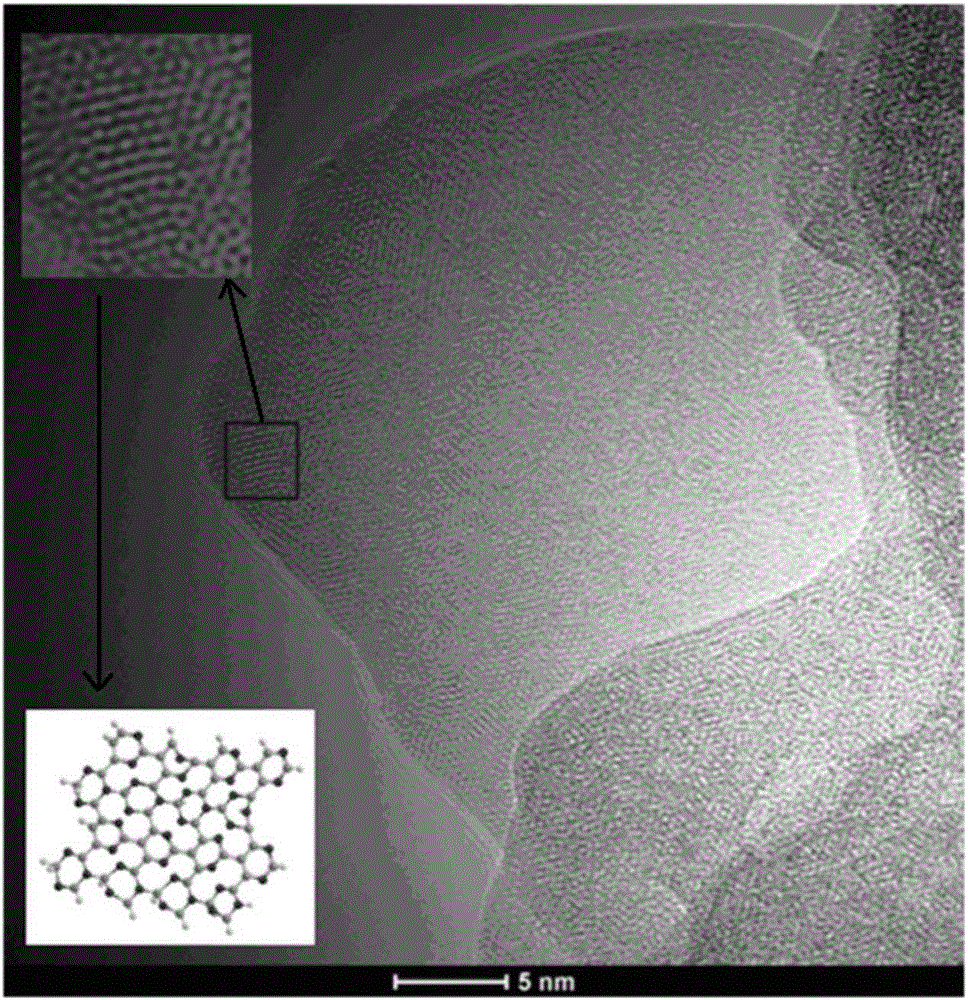

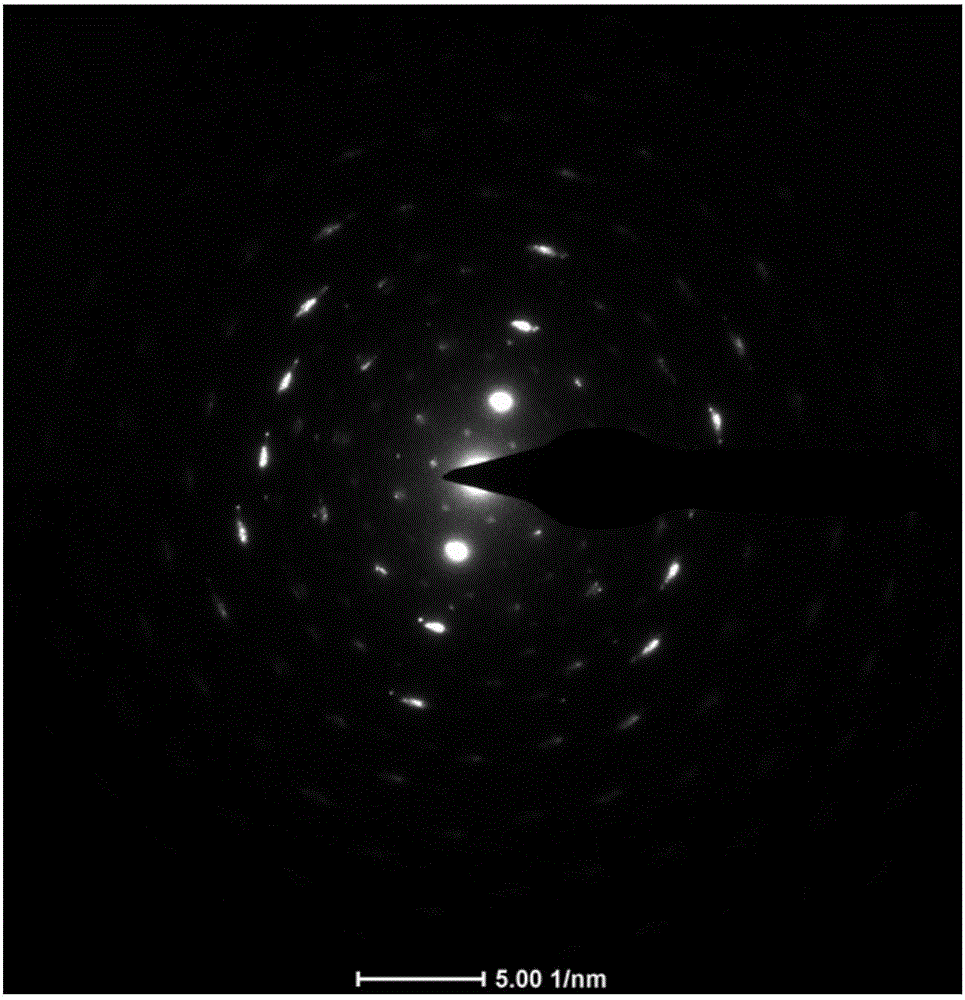

[0039] At room temperature, weigh 0.0526gg-C 3 N 4 , grind to powder in an agate mortar, sieve out the particles with a particle size greater than 0.106mm (use a 140 mesh sieve), and add 30ml of HNO with a mass concentration of 65% 3 After being stirred evenly, it was left to stand for 24 hours. After being stirred evenly again, it was sonicated for 3 hours at intervals on an ultrasonic instrument with a frequency of 40,000 Hz in a 65°C water bath using a centrifuge tube, and washed with water until the pH was 6. After drying and grinding into powder, add 50ml of absolute ethanol, stir evenly, and ultrasonicate for 3 hours at intervals. Centrifuge and wash with absolute ethanol, dry and grind at 80°C to obtain a single layer of g-C 3 N 4 . The monolayer g-C 3 N 4 The interatomic distance of the material is about 0.35nm, and the electron diffraction at any position will show a six-membered ring structure, and the thickness is about 0.334nm, and the size is about 500nm-1um...

Embodiment 12

[0041] At room temperature, weigh 0.0507gg-C 3 N 4 , grind to powder in an agate mortar, sieve out the particles with a particle size greater than 0.106mm (use a 140 mesh sieve), add 30ml of HNO with a mass concentration of 50% 3 After stirring evenly, let it stand for 24 hours. After stirring again, conduct ultrasonic treatment at intervals of 3 hours on an ultrasonic instrument with a frequency of 40,000 Hz in a 60°C water bath, wash with water until the pH is 6, dry and grind it into powder, and then add 50ml of absolute ethanol and stir. Uniform, interval sonication for 3h. Centrifuge and wash with absolute ethanol, dry and grind at 80°C to obtain a single layer of g-C 3 N 4 . This monolayer g-C 3 N 4 The distance between atoms is about 0.35nm, the thickness is 0.334nm, and the size is about 450nm-1um. The TEM image of the material is shown in Figure 5 shown.

Embodiment 13

[0043] At room temperature, weigh 0.0571gg-C 3 N 4 , grind to powder in an agate mortar, sieve out the particles with a particle size larger than 0.106mm (use a 140 mesh sieve), and add 30ml of HNO with a mass concentration of 32% 3 After being stirred evenly, it was left to stand for 24 hours. After being stirred evenly again, it was ultrasonically treated for 3 hours at intervals on an ultrasonic instrument with a frequency of 40,000 Hz in a 65°C water bath, and washed with water until the pH was 6. After drying and grinding into powder, add 50ml of absolute ethanol, stir evenly, and ultrasonicate for 3 hours at intervals. Centrifuge and wash with absolute ethanol, dry and grind at 60°C to obtain a single layer of g-C 3 N 4 . This monolayer g-C 3 N 4 The distance between atoms is about 0.35nm, and the electron diffraction at any position will show a six-membered ring structure with a thickness of about 0.334nm and a size between about 700nm and 5um. The TEM image of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com