Branched hydrophobic associated polymer oil-displacing agent and preparation method thereof

A hydrophobic association, polymer technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of polymer shear resistance, temperature resistance and salt resistance, polymer molecular chain curling, etc. The water solubility of the polymer is reduced and other problems, so as to achieve the effect of good injection ability and fluidity control ability, improved salt resistance and high viscosity increasing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh 2.619 grams of skeleton monomer and 1.437 grams of maleic anhydride into different beakers respectively, then add 20.16 grams and 8.09 grams of dimethyl sulfoxide to stir and dissolve evenly, and mix the skeleton with a molar ratio of 1:8 The dimethyl sulfoxide solution of the monomer is slowly added dropwise to the dimethyl sulfoxide solution of maleic anhydride, nitrogen gas is passed during the dropwise addition, and the system is placed in an ice-salt bath, and the skeleton monomer solution is added dropwise Afterwards, the stirring is continued until the temperature of the reaction liquid system no longer rises, and the functionalized skeleton monomer is obtained by repeated precipitation with chloroform.

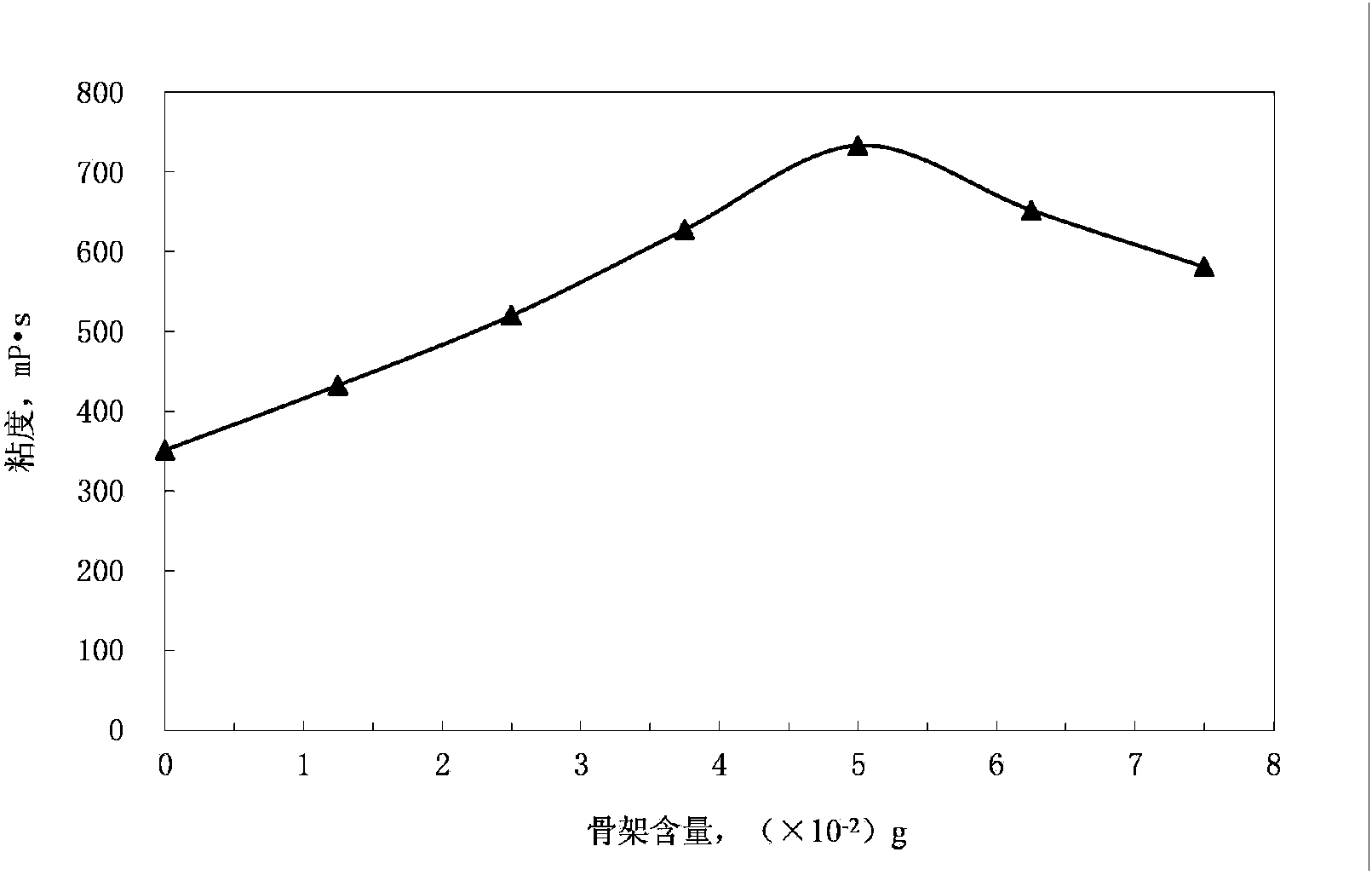

[0047] Weigh 20 grams of acrylamide (AM), 5 grams of acrylic acid (AA), functionalized backbone monomers 0, 0.0125 grams, 0.025 grams, 0.0375 grams, 0.05 grams, 0.0625 grams, 0.075 grams, dimethylallyl-N - 0.8 grams of alkylammonium chloride and 74 grams o...

Embodiment 2

[0049] The functionalized backbone monomer was prepared as in Example 1.

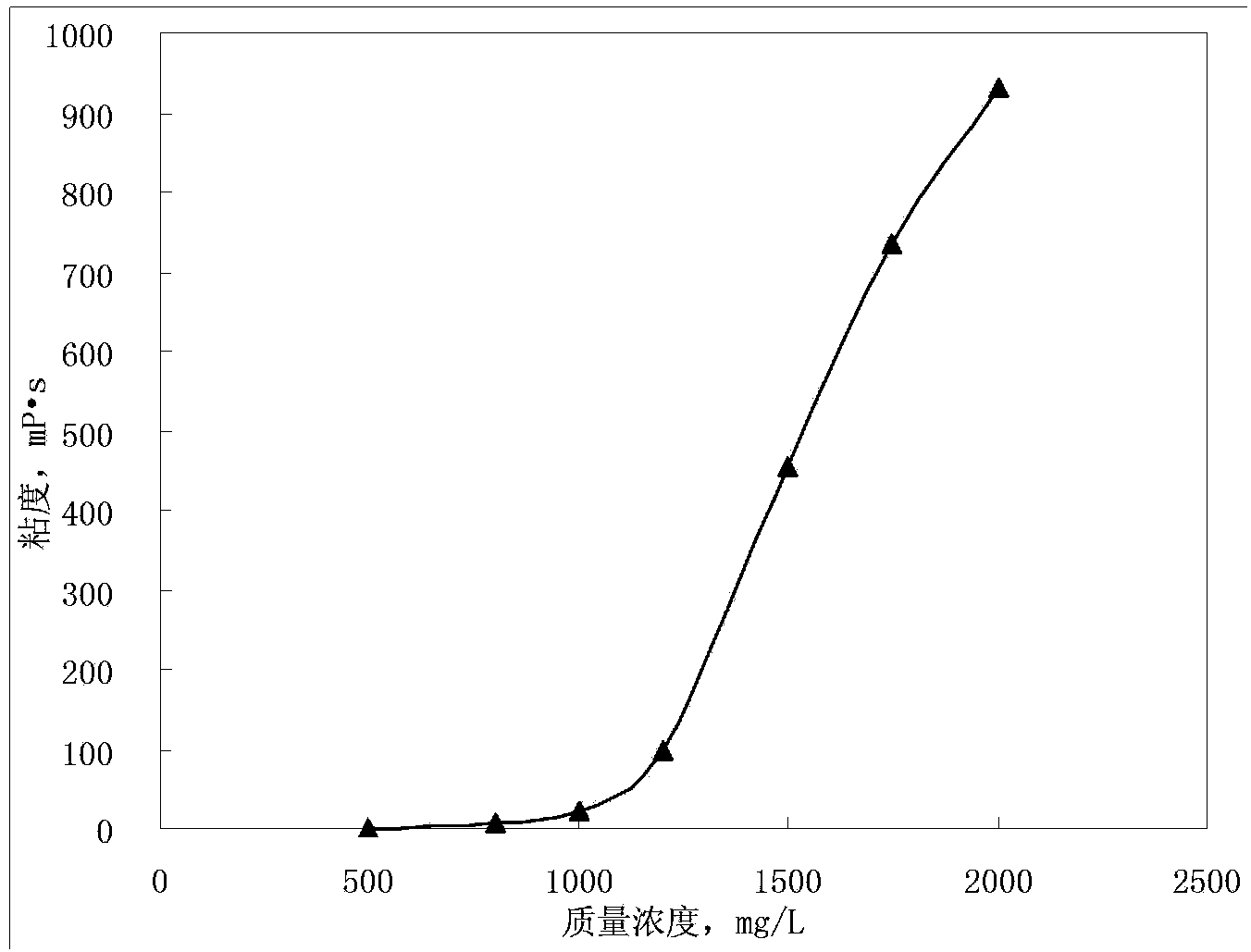

[0050] Weigh 20 grams of acrylamide (AM), 5 grams of acrylic acid (AA), 0.05 grams of functionalized backbone monomers, 0.2 grams, 0.4 grams, 0.8 grams, and 1.2 grams of dimethylallyl-N-alkylammonium chloride . Each of 0.26 g of sodium, 0.052 g of chain transfer agent sodium methoxide, and 4.8 mg of oxidation-reduction initiator sodium bisulfite and ammonium persulfate were reacted for 8 hours to obtain five kinds of jelly-like polymers.

[0051] 2. Performance test of branched hydrophobic association polymer

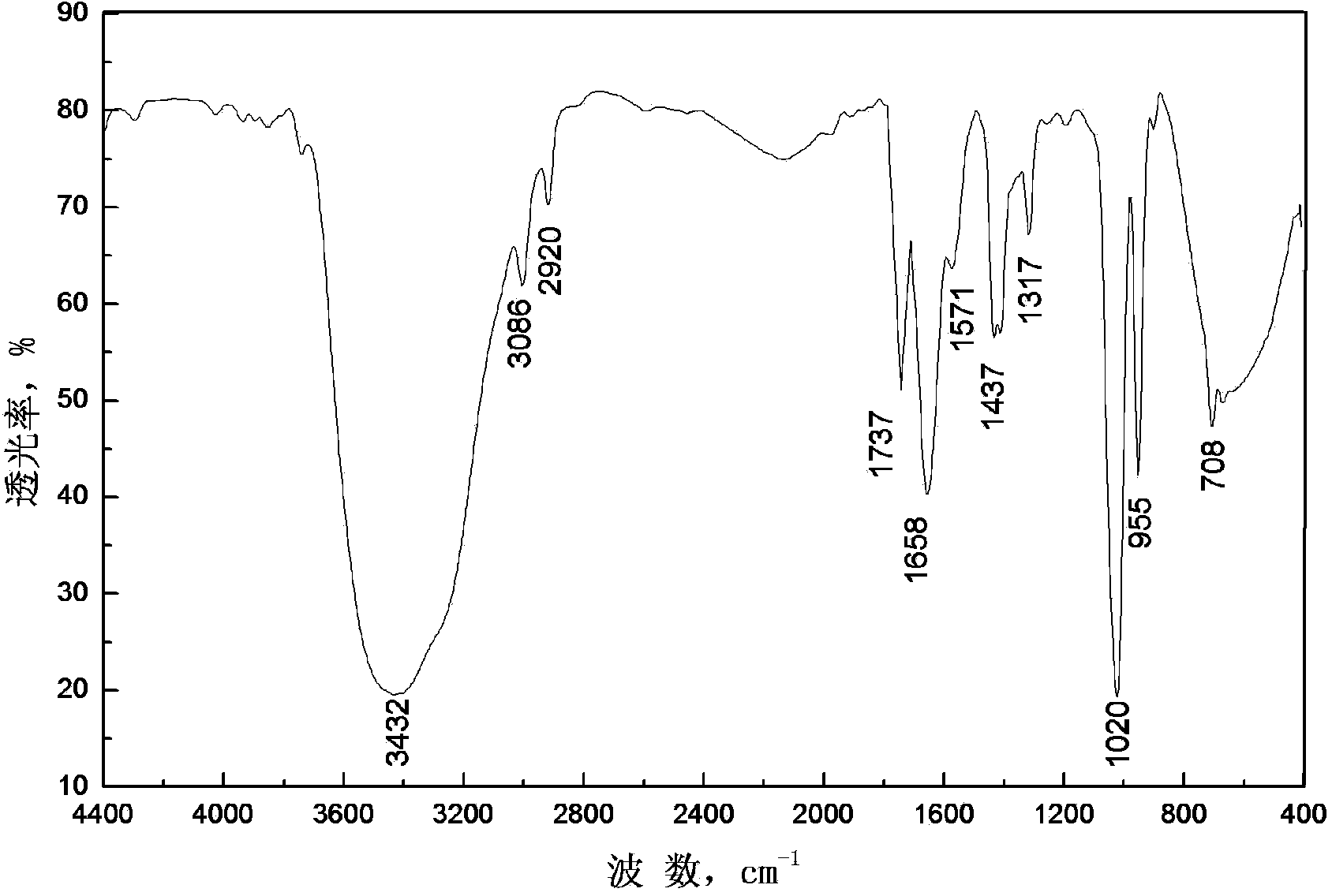

[0052] Infrared spectra of functionalized backbone monomers see figure 1 . The figure shows: wave number 3432 (NH stretching vibration), 3089 (NH in-plane bending vibration), 2920 (CH 2 stretching vibration), 1737 (C=O stretching vibration), 1658 (C=O stretching vibration, C=C stretching vibration), 1020 (C-N stretching vibration), 955 (=C-H out-of-plane bending vibration), 708 (NH out-of-pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com