Detergent for stainless steel heat exchange coil pipe of industrial fermentation tank and preparation method thereof

A technology of cleaning agent and fermenter, which is applied in the field of industrial fermenter stainless steel heat exchange coil cleaning agent and its preparation, can solve the problems of dirt shedding, general cleaning effect, complex supporting equipment, etc., and achieve good descaling and anti-corrosion, The inner wall is smooth and smooth, avoiding the effect of secondary deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

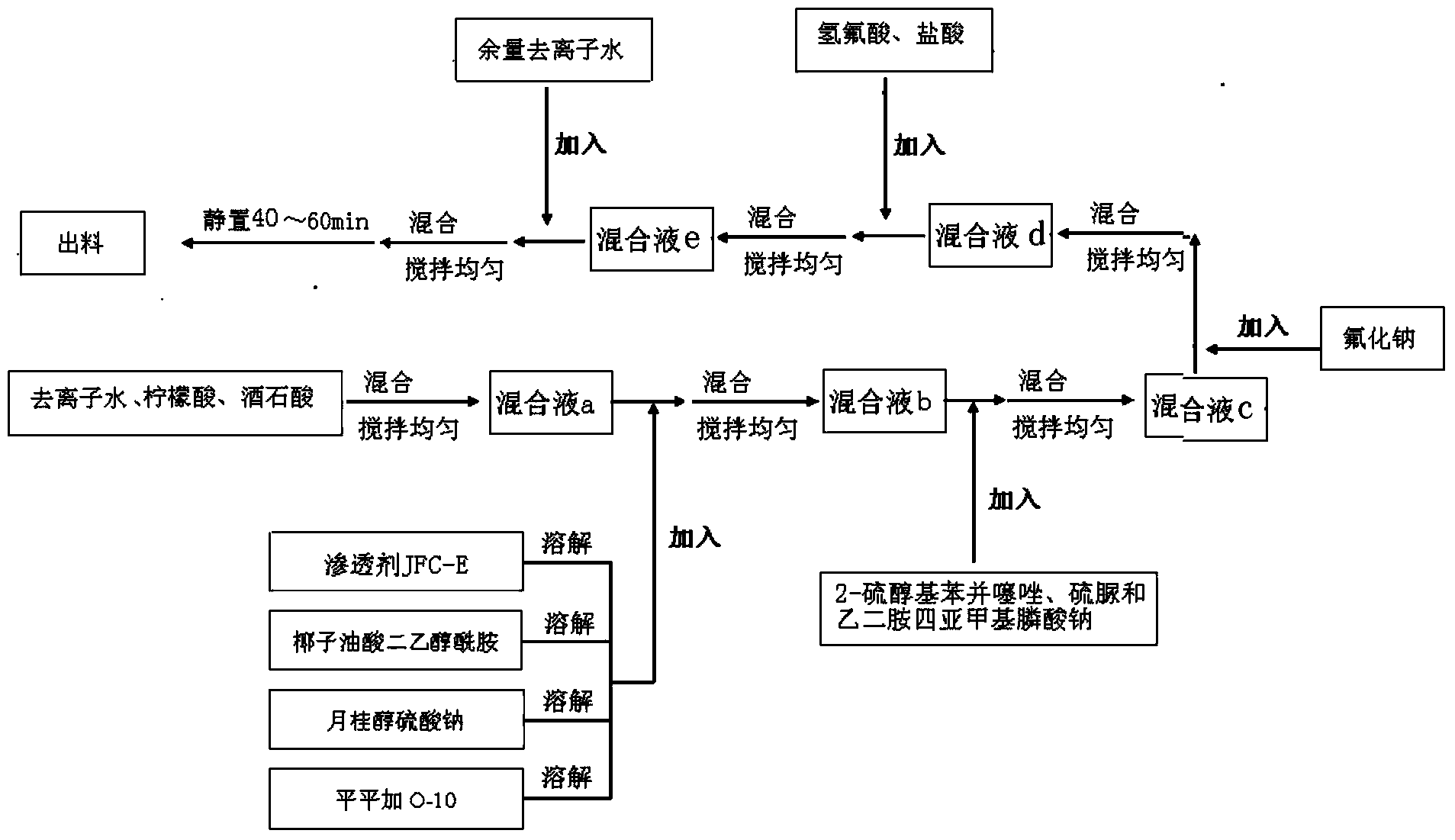

[0065] (1) Add 233.2kg of deionized water, 30kg of citric acid and 50kg of acetic acid into the reaction kettle, stir at a speed of 40rpm for 15min, and prepare the mixture a;

[0066] (2) Take 233.2kg of deionized water, dissolve 50kg of penetrant JFC-E, 40kg of coconut oleic acid diethanolamide, 20kg of sodium lauryl sulfate and 15kg of Pingpingjia O-10, and add the dissolved components into the mixture In liquid a, stir at a speed of 15 rpm for 40 minutes to prepare mixed liquid b;

[0067] (3) Add 2kg of 2-mercaptobenzothiazole, 1kg of thiourea and 0.3kg of sodium ethylenediaminetetramethylene phosphonate to the mixture b, and stir for 30min at a speed of 30rpm to prepare the mixture c ;

[0068] (4) Add 2kg of sodium fluoride to the mixed solution c, and stir at a speed of 40rpm for 10min to prepare the mixed solution d;

[0069] (5) Add 40kg of hydrofluoric acid and 50kg of hydrochloric acid to the mixed solution d, and stir at a speed of 30rpm for 10min to prepare the...

Embodiment 2

[0080] (1) Add 243.6kg of deionized water, 40kg of citric acid and 20kg of acetic acid into the reaction kettle, stir at a speed of 60rpm for 10min, and prepare the mixture a;

[0081] (2) Take 243.6kg of deionized water, dissolve 65kg of penetrant JFC-E, 20kg of coconut oleic acid diethanolamide, 10kg of sodium lauryl sulfate and 30kg of Pingpingjia O-10, and add the dissolved components to mix In liquid a, stir at a speed of 20 rpm for 30 minutes to prepare mixed liquid b;

[0082] (3) Add 1 kg of 2-mercaptobenzothiazole, 2 kg of thiourea and 0.3 kg of sodium ethylenediamine tetramethylene phosphonate to the mixed liquid b, and stir at a speed of 40 rpm for 20 minutes to prepare the mixed liquid c;

[0083] (4) Add 1 kg of sodium fluoride to the mixed solution c, and stir for 5 minutes at a speed of 50 rpm to prepare the mixed solution d;

[0084] (5) Add 50 kg of hydrofluoric acid and 30 kg of hydrochloric acid to the mixed liquid d, and stir at a speed of 50 rpm for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com