Effective use of yeast and yeast extract residue

A technology of yeast extract and yeast, which is applied in the field of seasoning and yeast protein, can solve the problems of difficult decomposition, difficult dietary fiber content, low utilization value, etc., achieve low allergenicity, reduce the amount of waste, and high protein content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

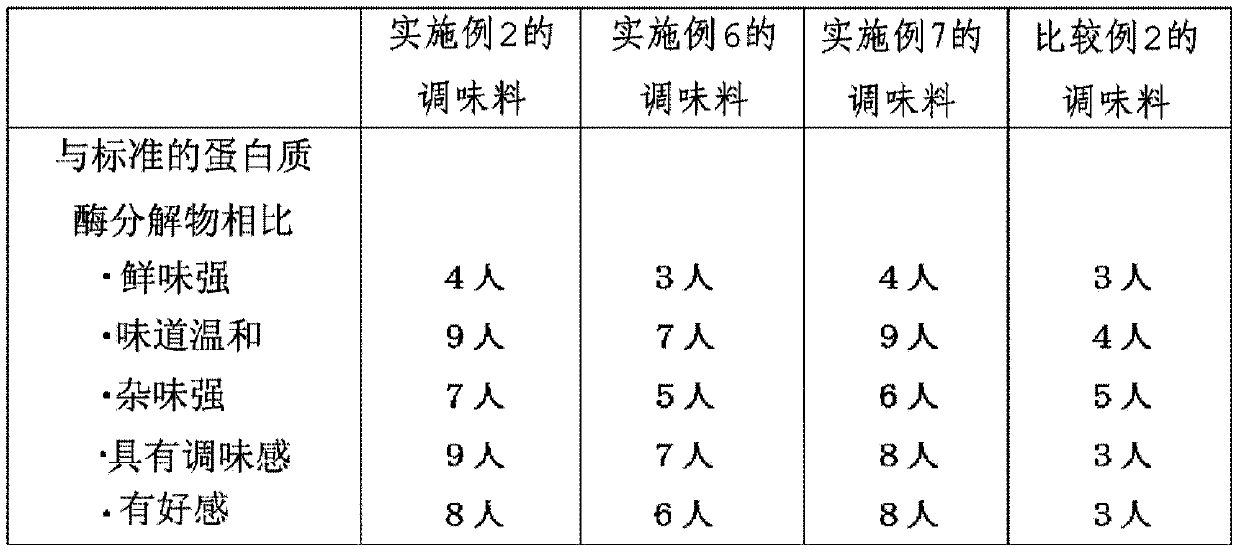

Examples

Embodiment 1

[0057] In the method for preparing the yeast extract of Candida utilis described in Example 3 of JP-A-2002-101846, after extracting the extract, the bacterial cell residue removed by centrifugation is obtained, and the bacterial cell residue is used Yeast cells as raw materials.

[0058] Suspend 1 kg of this yeast cell in water, adjust the concentration to 10%, then, after adjusting 40°C and pH 4.5, add 30 g of cell wall dissolving enzyme ("Filtrase BRX" produced by DSM ヅヤパン Co., Ltd.) for 5 hours, and then Heat treatment at 70°C for 20 minutes, and then use a centrifuge to separate into a cell wall-based component and a protein-based component.

[0059] The protein-based fraction was dried to obtain 611 g of yeast protein. The protein content of this yeast protein was determined to be 72% by the Kjeldahl method.

[0060] On the other hand, the cell wall-based fraction was dried to obtain 186 g of a yeast cell wall fraction. The dietary fiber content in this yeast cell wall...

Embodiment 2

[0062] Suspend 1 kg of yeast cell "KR Yeast" (manufactured by Kohin) after extracting the yeast extract of Candida utilis in water, adjust the concentration to 10%, and then add 3 g of cell walls after adjusting the pH to 6.0 at 40°C Dissolving enzyme ("Denichimu GEL" produced by Nagase Chemtex Co., Ltd.) was acted for 5 hours, followed by heat treatment at 70°C for 20 minutes, and then separated into cell wall-based components and protein-based components with a centrifuge. components.

[0063] The protein-based fraction was dried to obtain 706 g of yeast protein. The protein content of the yeast protein measured by the Kjeldahl method was 84%.

[0064] On the other hand, the cell wall-based fraction was dried to obtain 318 g of a cell wall fraction. The dietary fiber content in this yeast cell wall fraction was measured to be 61% by the enzyme-gravimetric method (analytical value of Japan Food Analysis Center).

[0065] Adjust the concentration of the obtained yeast prote...

Embodiment 3

[0067] After suspending 1 kg of cultured yeast cells of Candida ruguens "Yeast MG" (manufactured by Kohin) in water and adjusting the concentration to 10%, after adjusting to 40°C and pH 6.0, 3 g of cell wall-dissolving enzyme (Nagasechem "Denachin-GEL" produced by Tex Corporation), acted for 5 hours, then heat-treated at 70°C for 20 minutes, and then separated into a cell wall-based component and a protein-based component with a centrifuge. The protein-based component was dried to obtain 320 g of yeast protein. The protein content of the yeast protein measured by the Kjeldahl method was 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com