Compound nanofiltration membrane for dye desalination and treatment of waste water during dye desalination, as well as preparation method of compound nanofiltration membrane

A composite nanofiltration membrane and wastewater treatment technology, which is applied in the direction of osmosis/dialysis water/sewage treatment, general water supply saving, chemical instruments and methods, etc., can solve the problems that limit the wide application of membrane technology, the surface inorganic materials are easy to fall off, and improve the application technology Cost and other issues, to achieve good dye desalination performance, high practical value, improve the effect of interception performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Immerse the polyvinylidene fluoride (PVDF) hollow fiber membrane in 1mol / L NaOH alkali solution at 60°C for 30 minutes, and then wash it with distilled water until the solution is neutral;

[0022] (2) immerse the treated hollow fiber membrane into the PVA solution of 0.5% by mass fraction, take it out and dry it, and then immerse it into the glutaraldehyde mass fraction of 30°C as 3%, and the concentrated sulfuric acid mass fraction as 6% Cross-linking in ethanol solution for 10 min. In the above process, the PVA coating solution was soaked for 3 times, respectively for 10 minutes, 10 minutes, and 1 minute, and each time it was dried, it was crosslinked with a crosslinking agent solution for 10 minutes.

[0023] (3) The hollow fiber composite membrane coated and crosslinked three times was then placed in an oven at 100° C. for heat setting for 10 minutes.

[0024] (4) Use 50ppm of Congo red (molecular weight: 696.68 Daltons), methyl orange (molecular weight: 327.3...

Embodiment 2

[0026] (1) Immerse the PVDF hollow fiber membrane in 1mol / L KOH alkali solution at 40°C for 30 minutes, and then wash it with distilled water until the solution is neutral;

[0027] (2) Immerse the alkali-treated hollow fiber membrane into a PVA mass fraction of 1%, nano-titanium dioxide (nano-TiO 2 ) with a mass fraction of 0.1% of PVA / nano-TiO 2 In the water solution, take out after 10 minutes to dry. Then immerse it in an ethanol solution with a mass fraction of succinic acid of 3% and an acid catalyst mass fraction of 1% at 40°C. After cross-linking treatment for 10 minutes, take it out to dry, and repeat immersion coating and cross-linking treatment twice. ;

[0028] (3) The hollow fiber composite membrane coated and crosslinked three times was then placed in an oven at 100° C. for heat setting for 10 minutes.

[0029] (4) Using 50ppm Congo red, methyl orange and methyl blue aqueous solutions respectively, the performance of the composite membrane was tested under a pr...

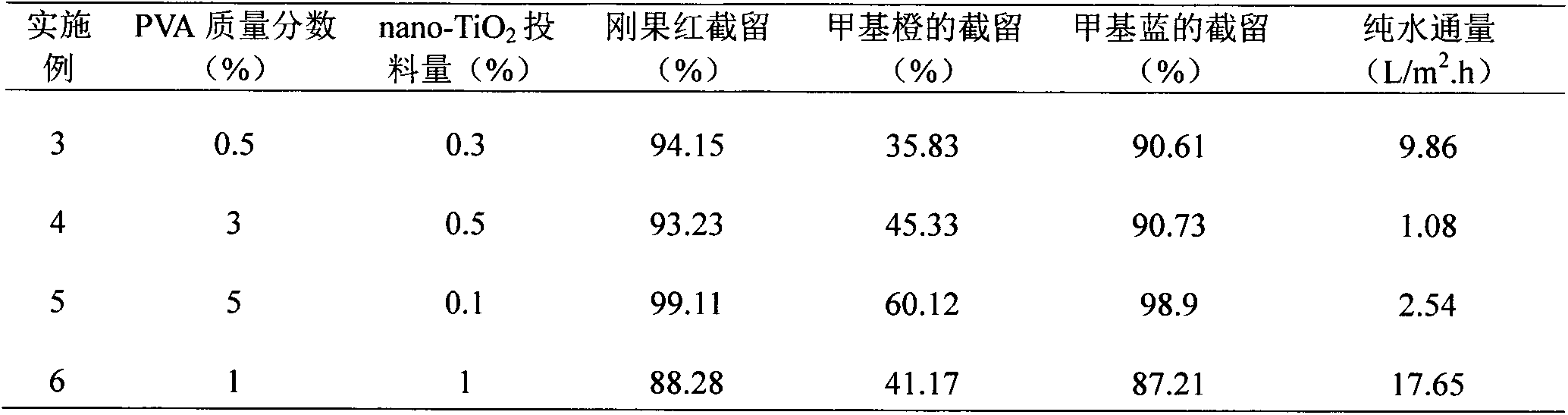

Embodiment 3-6

[0031] Keep the content and temperature of lye and crosslinking agent solution constant, change the mass fraction of PVA and nano-TiO 2 The input amount, other operating conditions are all the same as example 1:

[0032] Table 1. Embodiment 3-6 concrete implementation scheme:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com