Surface sizing agent and preparation method thereof, sizing solution and sizing paper

A technology of surface sizing agent and sizing liquid, applied in the field of sizing paper, can solve the problems of polluted environment, low solid content, poor dispersibility, etc., and achieve the effect of good use effect, high performance, and improved waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of this surface sizing agent, it comprises the steps:

[0017] (1) Prepare cationic starch solution.

[0018] The mass percent concentration of the cationic starch solution is 30%-40%, and the pH value is 4-6. The cationic starch is prepared by reacting raw starch with cationic etherification agent. The cationic starch liquid is made by using raw starch, or directly mixed with purchased cationic starch and water.

[0019] (2) Add monomer solution and initiator solution to the above-mentioned cationic starch liquid to carry out polymerization reaction to prepare copolymer emulsion of cationic starch grafted monomer.

[0020] The polymerization reaction is under a nitrogen atmosphere, because there is a large amount of oxygen under the air, which will reduce the efficiency of the initiator and even produce unnecessary by-products.

[0021] During the polymerization reaction, the temperature of the mixed solution system is kept at 30-65° C., and t...

Embodiment 1-5

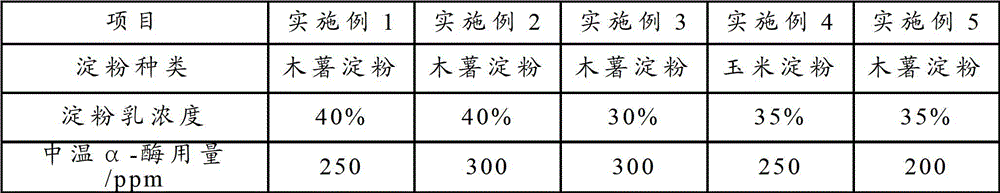

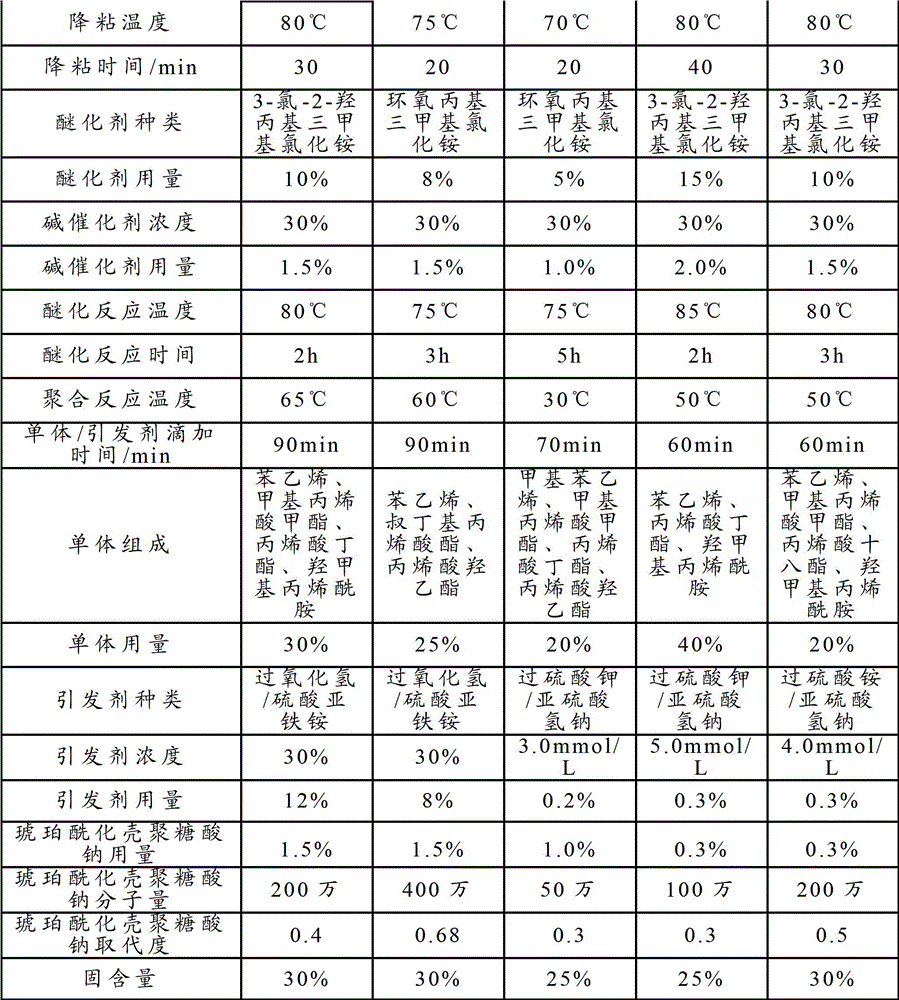

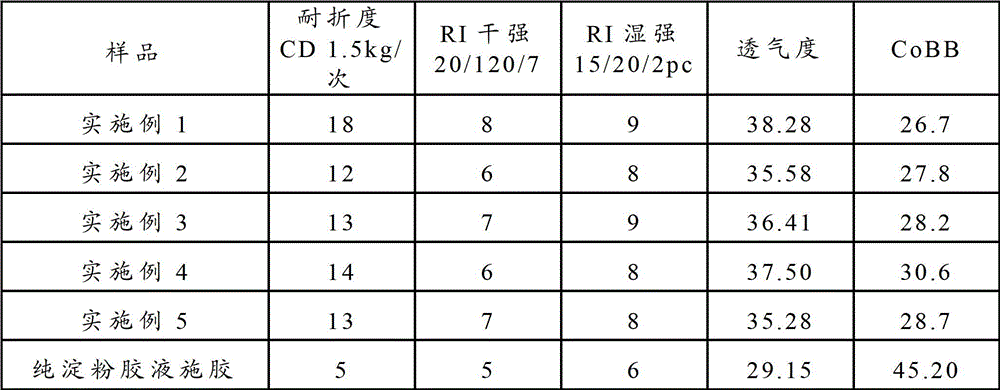

[0049] Examples 1-5 were respectively prepared according to the methods described below to prepare 5 groups of surface sizing agents, and the specific process parameters are shown in Table 1.

[0050] A certain amount of raw starch is added into water to disperse under stirring state to obtain starch milk, and the medium-temperature α-amylase added to the starch milk reacts at a certain temperature for a certain period of time. Add a cationic etherification agent pre-activated by a 30% alkaline catalyst to the above starch liquid, maintain a certain temperature for etherification reaction, and then add glacial acetic acid to adjust the pH to obtain a cationized starch liquid. The monomer-containing solution and the initiator solution are simultaneously but separately metered into the cationic etherified starch solution at a constant feeding rate to carry out polymerization reaction, and the polymerization reaction is carried out under nitrogen atmosphere. 10 minutes after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com