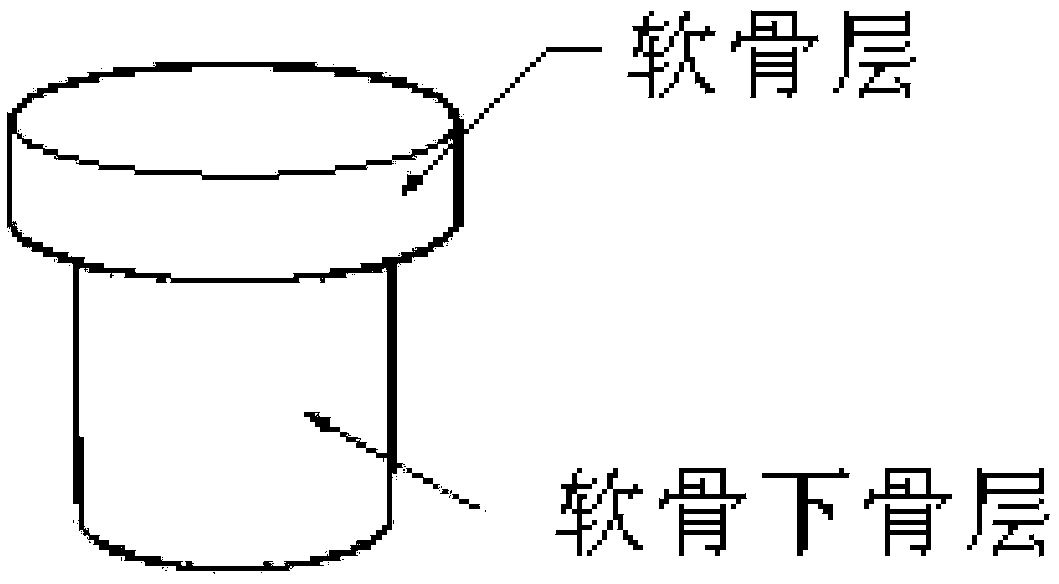

Dual-layer composite scaffold for repairing cartilage of tissue engineered bone and preparation method thereof

A tissue engineering bone and cartilage repair technology, applied in medical science, prosthesis, etc., can solve the problems of difficult degradation and poor biocompatibility, and achieve the effect of simple method, good biocompatibility and good osteoconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the following examples, the preparation method of photopolymerized modified hyaluronic acid gel comprises the following steps:

[0037] An aqueous solution of sodium hyaluronate (molecular weight: 66-90 kilodaltons) with a mass concentration of 1-5% is stirred and dissolved at the freezing point, and then mixed with methacrylic anhydride. The concentration of methacrylic anhydride is hyaluronic acid 20 times the molar concentration of sodium bicarbonate, adjust the pH so that the pH value is always greater than 8, stir and react at freezing point for 24 hours, put it into the dialysis membrane and dialyze with 50 times the volume of deionized water for 3 days, freeze-dry for 48 hours, and then mix with normal saline and The cross-linking agent I2959 was mixed to obtain a photopolymerized modified hyaluronic acid gel; the concentration of the cross-linking agent I2959 was 0.05wt%.

Embodiment 1

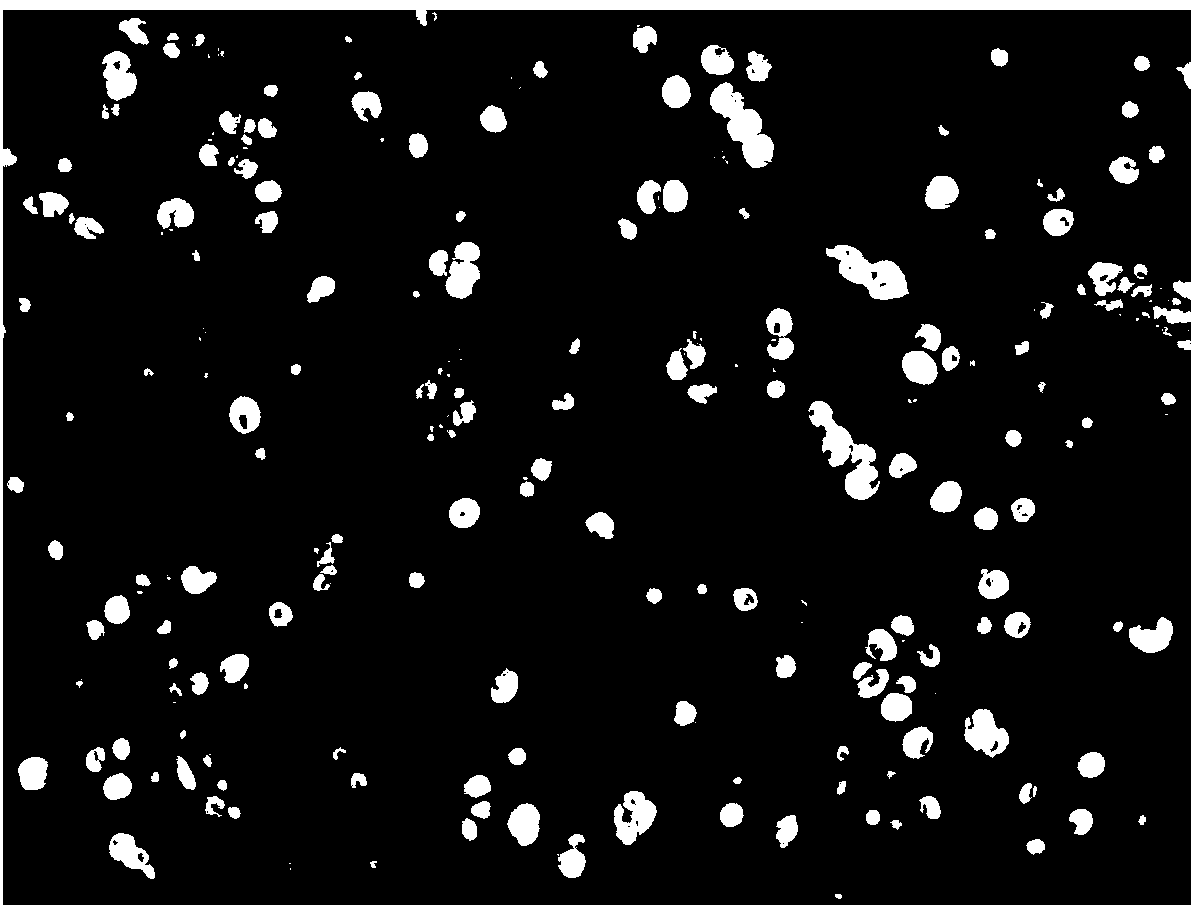

[0039] The preparation method of the double-layer composite scaffold for tissue engineering osteochondral repair comprises the following steps: filter and sterilize the modified hyaluronic acid gel with photopolymerization through a 0.02 μm filter membrane, and induce and transform chondrocytes from bone marrow mesenchymal stem cells in vitro After mixing evenly, make the cell concentration 40×10 6 / ml, the hydrogel complex with a mass concentration of modified sodium hyaluronate of 1% and a mass concentration of I2959 of 0.05% is put into a mold with a diameter of 5mm and a height of 5mm, and is passed through a distance of an ultraviolet lamp with a wavelength of 320-400nm After irradiating at 15cm for 10 minutes, cross-linking forms a hybrid gel; place the porous silicate bioglass scaffold on the hybrid gel, add 50 μL of modified hyaluronic acid gel with photopolymerization, and UV light with a wavelength of 320-400nm A double-layer composite scaffold for tissue engineering...

Embodiment 2

[0042] The preparation method of the double-layer composite scaffold for tissue engineering osteochondral repair includes the following steps: sterilize the modified hyaluronic acid gel with photopolymerization in an ultra-clean bench for half an hour by ultraviolet light, and then dissolve it in sterile PBS containing I2959 solution, and mixed with adipose-derived stem cells in vitro induced transformation of chondrocytes to make a cell concentration of 5 × 10 6 / ml, the hydrogel complex with a mass concentration of sodium hyaluronate of 2% and a mass concentration of I2959 of 0.05% is placed in a mold with a diameter of 5mm and a height of 5mm, and is placed at a distance of 25cm by an ultraviolet lamp with a wavelength of 320-400nm. After irradiating for 15 minutes, cross-link to form a mixed gel; place the porous borosilicate bioglass scaffold on the mixed gel, add 30 μL of modified hyaluronic acid gel with photopolymerization, and use a UV lamp with a wavelength of 320-400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com