Preparation method for magnetic carbon fibers with good interface property

A technology of interface performance and carbon fiber, which is applied in the direction of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problem of not being able to improve the interface performance of carbon fiber at the same time, and achieve the effect of improving interface performance and interfacial bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first step is to prepare and mix concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 3:1, place T800 carbon fiber in it, oxidize at 60°C for 4 hours, wash with distilled water until neutral drying.

[0020] In the second step, the carbon fiber prepared in the first step is placed in thionyl chloride for acyl chloride reaction at 76° C. for 48 hours, and then dried.

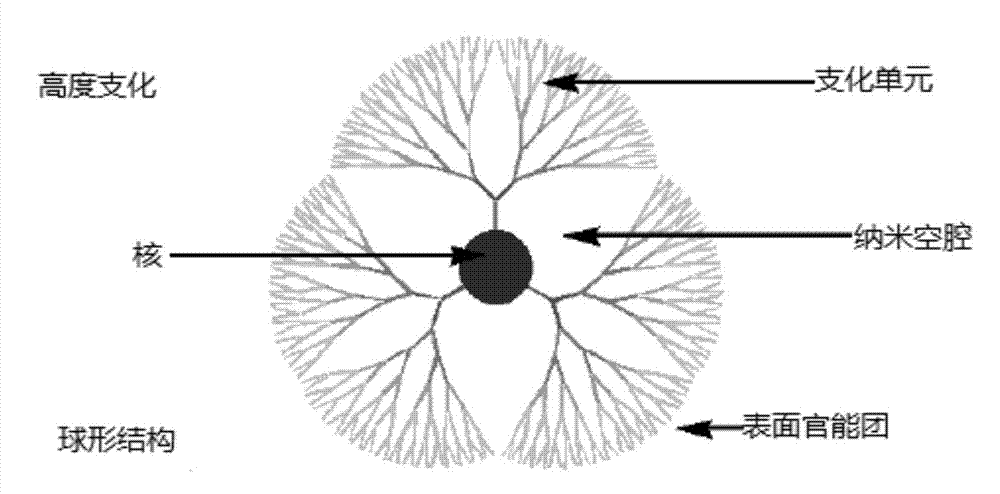

[0021] The third step is to prepare 50ml of N,N-dimethylformamide solution with a mass concentration of 5% of the fifth-generation polyamide-amide dendrimer, weigh 5g of the carbon fiber prepared in the second step, and place it in it at 100°C. Under the condition of reaction for 24h, washed with acetone repeatedly five times and dried.

[0022] The 4th step, preparation concentration is the cobalt dichloride (CoCl2) of 0.1mol / L respectively 2 .6H 2 O), ferrous chloride (FeCl 2 .4H 2 O) and sodium borohydride solution.

[0023] Step 5: Add 21 mL of the cobalt dichloride sol...

Embodiment 2

[0026] The difference between this example and Example 1 is that the volume ratio of the cobalt dichloride solution and the ferrous chloride solution is 1:1.

Embodiment 3

[0028] The difference between this example and Example 1 is that the volume ratio of the cobalt dichloride solution and the ferrous chloride solution is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com