Method for growing hexagonal Co(OH)2 on surface of metal foamed nickel

A technology of metal foam and surface growth, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of complex preparation process, poor capacitance characteristics and high specific capacitance value, and achieve the effects of simple and easy control of reaction conditions, short drying process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

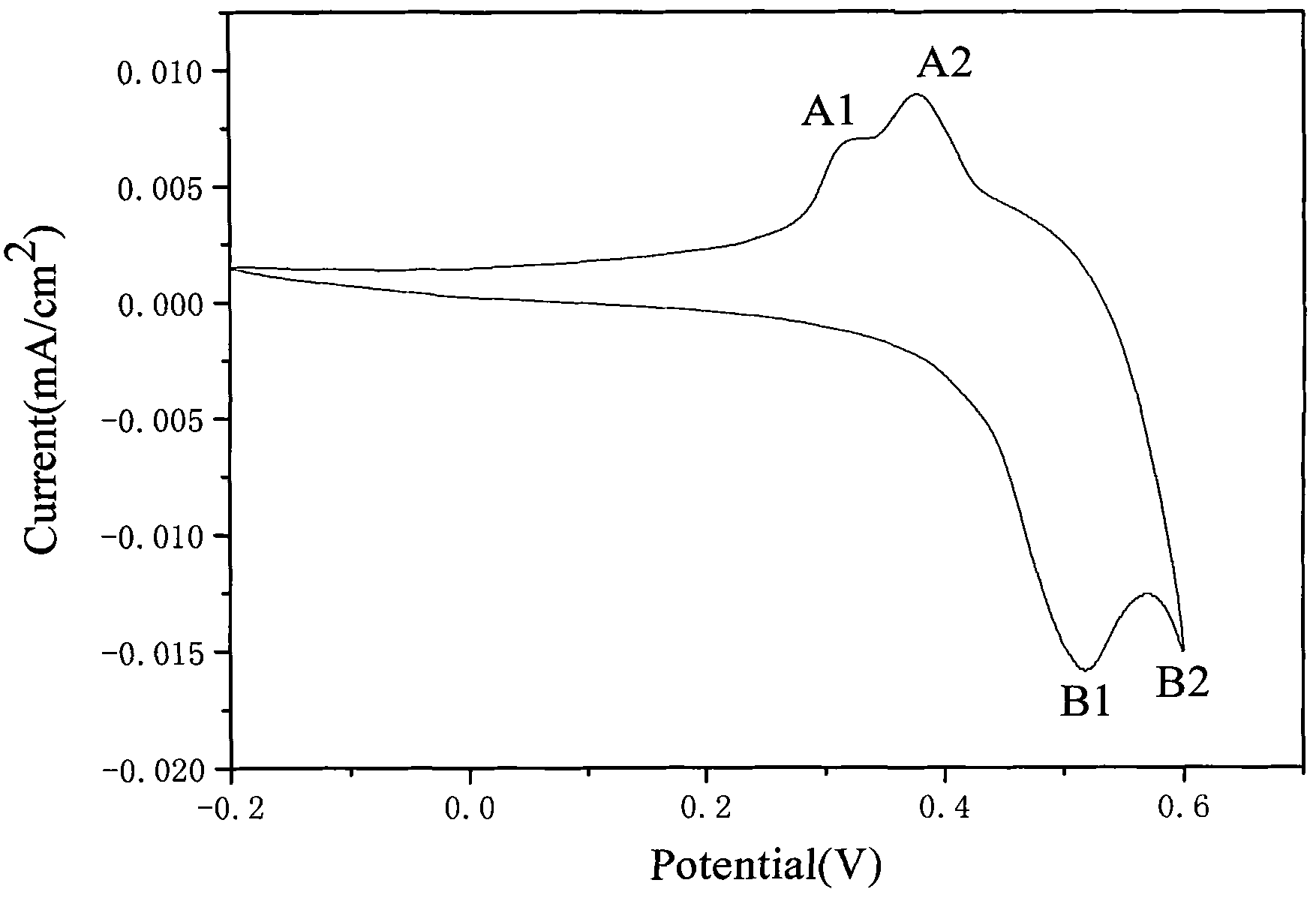

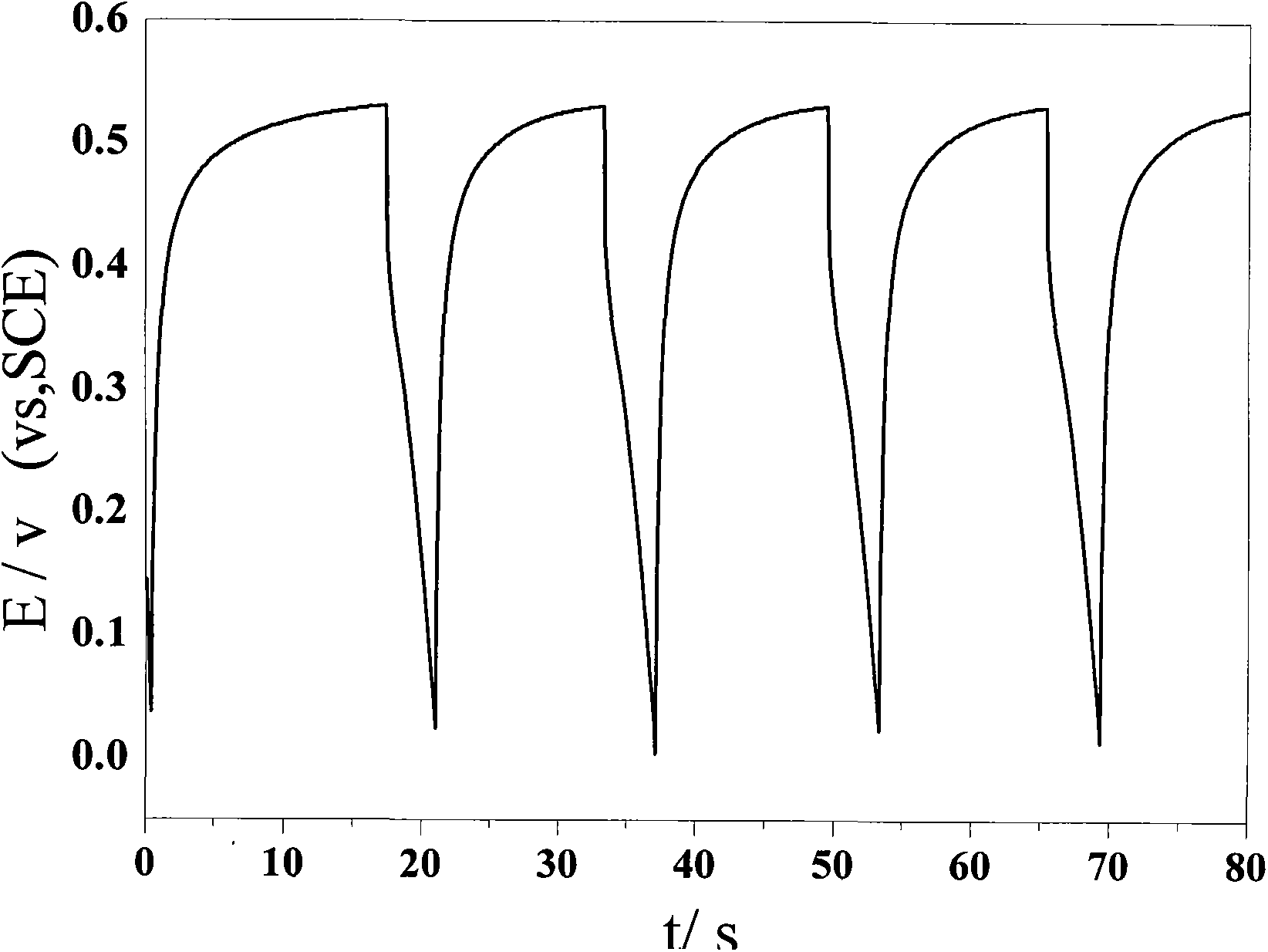

[0026] First put the weighed 0.8731g of cobalt nitrate hexahydrate and 0.1667g of ammonium fluoride into a beaker, then slowly add 9mL of ammonia solution with a mass fraction of 28% and 21mL of deionized water, the pH value is 12, and transfer to the hydrothermal reaction kettle In the liner; cut 2×3cm, metal foam nickel with a mass of 0.5g and put it into the above solution; and set the hydrothermal reaction temperature at 120°C, after 4 hours, take out the sample, and wash it with deionized water and absolute ethanol successively After washing, the sample was placed in a constant temperature drying oven at 60°C and taken out after 4 hours. The XRD test analysis shows that, in which β-Co(OH) 2 and the presence of metallic nickel ( figure 1 a). From scanning electron microscope pictures ( figure 1 b, c, d, e and f) It can be seen that the surface of the nickel foam is covered with hexagonal cobalt hydroxide sheets, the thickness is about 3.0um, and the hexagon side length ...

Embodiment 2

[0035] First put the weighed 2.1414g cobalt chloride hexahydrate and 0.5000g ammonium fluoride into the beaker, then slowly add 9mL ammonia solution with a mass fraction of 28% and 21mL deionized water, the pH value is 9, transfer to the hydrothermal reaction In the kettle liner; cut 2×3cm, metal foam nickel with a mass of 0.5g is put into the above solution; and set the hydrothermal reaction temperature at 150°C, after 2h, take out the sample, and successively wash with deionized water, anhydrous Wash with ethanol, place the sample in a constant temperature drying oven at 80°C, and take it out after 1 hour. From scanning electron microscope pictures ( Figure 4 It can be seen from a and b) that the surface of the nickel foam is covered with hexagonal cobalt hydroxide sheets, the thickness of which is about 5-10.0um, and the side length of the hexagon is about 20um. The electrochemical properties of the material were tested by the three-electrode method (electrolyte solution:...

Embodiment 3

[0039] First put the weighed 1.4555g cobalt nitrate hexahydrate, 2.3800g hexahydrate and cobalt chloride and 0.8385g ammonium fluoride into the beaker, then slowly add 45mL of ammonia solution with a mass fraction of 28% and a certain amount of deionized water, Add ammonium carbonate to adjust the pH value to 10, transfer it to the liner of the hydrothermal reaction kettle; cut 2×3cm, and put the metal foam nickel with a mass of 0.5g into the above solution; and set the hydrothermal reaction temperature to 130°C, and the time is After 4 hours, the sample was taken out, washed successively with deionized water and absolute ethanol, placed in a constant temperature drying oven at 70°C, and taken out after 2 hours. From scanning electron microscope pictures ( Figure 7 ) It can be seen that the hexagonal cobalt hydroxide sheet has a thickness of about 5.0um and a hexagonal side length of about 15um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com