A kind of passivation method of cadmium zinc telluride crystal surface

A crystal surface, cadmium zinc telluride wafer technology, applied in semiconductor devices, sustainable manufacturing/processing, electrical components, etc., can solve the problems of complexity, heating or ultraviolet irradiation, etc., to achieve low processing cost, no harsh processing conditions, Simple effect of passivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

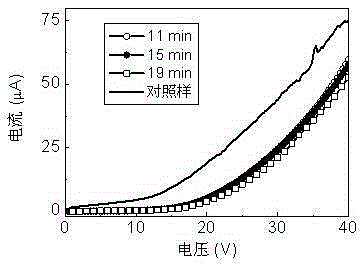

Embodiment 1

[0021] A passivation method for a cadmium zinc telluride crystal surface, specifically comprising the steps of:

[0022] (1) Preparation of passivation solution

[0023] Wash the beaker 3 times with deionized water, slowly add 3.6g of thiourea into the beaker with 40g of deionized water, stir evenly to obtain passivation solution after all the thiourea is dissolved;

[0024] The above passivation solution is calculated by mass ratio, that is, thiourea: deionized water is 9:100;

[0025] (2), passivation treatment

[0026] Put the cadmium zinc telluride wafer with the electrode prepared into the passivation solution obtained in step (1), soak for 11 minutes, and take out the cadmium zinc telluride wafer;

[0027] (3) Cleaning of CdZnTe wafer

[0028] Wash the CdZnTe wafers taken out in step (2) three times with deionized water, and then one time with absolute ethanol;

[0029] (4) Dry the CdZnTe wafer cleaned with absolute ethanol in step (3) with an ear cleaning ball to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com