Method for preparing bacterial cellulose compounded amnion extracellular matrix material containing collagen

A technology of bacterial cellulose and collagen, applied in catheters, medical science, prostheses, etc., can solve problems such as easy wrinkling and tearing, poor biomechanical properties, and difficult-to-refold tissue, and achieve a good three-dimensional network structure and preparation The process is simple and easy, and the effect of biocompatibility is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

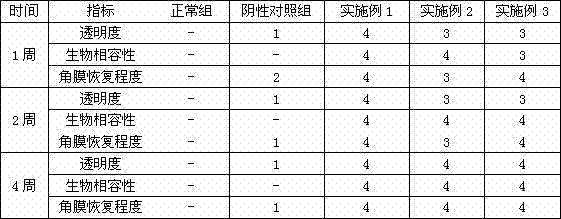

Examples

Embodiment 1

[0024]Acetobacter xylinum, which can secrete bacterial cellulose, was selected to prepare seed mash with a strain concentration of 30%. The collagen was dissolved in 1wt% acetic acid aqueous solution and mixed with the medium to obtain a fermentation medium containing 0.5wt% collagen. Mix the seed mash with the collagen-containing fermentation medium and place it in a culture container. The liquid level of the mixed solution in the culture container is 0.5 cm, and culture it for 1 day to obtain hydrogel-like bacterial fibers with a film thickness of 0.5 cm. Vein / Collagen Membrane.

[0025] The amniotic membrane extracellular matrix material is taken from a safe source, processed to remove cells, fat and soluble antigens, and dried and sterilized, soaked in the culture medium, and spread on the upper surface of the bacterial cellulose / collagen membrane after it is completely wet. Wherein, the sponge layer of the amnion extracellular matrix material is in contact with the upper...

Embodiment 2

[0027] Rhizobia and Pseudomonas, which can secrete bacterial cellulose, were selected and activated to prepare seed mash with a strain concentration of 40wt%. The collagen was dissolved in 1.5wt% acetic acid aqueous solution and mixed with the medium to obtain a fermentation medium containing 1wt% collagen. Mix the seed mash with the collagen-containing fermentation medium and place it in a culture container. The height of the mixed solution in the culture container is 1 cm, and culture it for 2 days to obtain hydrogel-like bacterial cellulose with a film thickness of 0.6 cm. / collagen membrane.

[0028] The amniotic membrane extracellular matrix material is taken from a safe source, processed to remove cells, fat and soluble antigens, and dried and sterilized, soaked in the culture medium, and spread on the upper surface of the bacterial cellulose / collagen membrane after it is completely wet. Wherein, the sponge layer of the amnion extracellular matrix material is in contact...

Embodiment 3

[0030] The seed mash with a strain concentration of 50wt% was prepared by activation of Sarcina and Alcaligenes that could secrete bacterial cellulose. The collagen was dissolved in 2wt% acetic acid aqueous solution and mixed with the medium to obtain a fermentation medium containing 2wt% collagen. After the seed mash is mixed with the fermentation medium containing collagen, it is placed in a culture container, the liquid level of the mixed solution in the culture container is 2 cm, and the hydrogel-like bacterial cellulose / Collagen membrane.

[0031] The amniotic membrane extracellular matrix material is taken from a safe source, processed to remove cells, fat and soluble antigens, and dried and sterilized, soaked in the culture medium, and spread on the upper surface of the bacterial cellulose / collagen membrane after it is completely wet. Wherein, the sponge layer of the amnion extracellular matrix material is in contact with the upper surface of the bacterial cellulose / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com