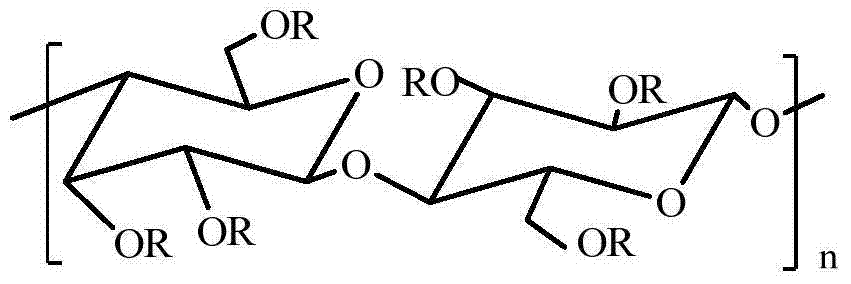

Cellulose-based guanidine salt bacteriostatic functional material and preparation method thereof

A technology of cellulose-based and functional materials, which is applied in the field of cellulose-based guanidine salt antibacterial functional materials and its preparation, and antibacterial materials, and can solve the problems of unpublished fresh-keeping technology uses, no separation and purification, and unsatisfactory antibacterial effects , achieve good bacteriostasis and biodegradability, simple and convenient operation, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of above-mentioned cellulose-based guanidinium salt antibacterial functional material, comprises the following steps:

[0041] (1) Dissolving cellulose with ionic liquid: When dissolving cellulose with ionic liquid, the temperature is 60-120°C, the stirring time is 6-10 hours, and the mass ratio of ionic liquid to cellulose is 8:1-20:1.

[0042] (2) Modified guanidine salt oligomer: Hexamethylenediamine hydrochloride and amine salt are added to isopropanol or isobutanol, and the mass ratio of hexamethylenediamine hydrochloride and amine salt is (2~7): 1. The synthesis temperature is 120-160°C, the reaction time is 16-24 hours, and the guanidinium salt oligomer is obtained, and then acrylic acid, acrylates or glycidyl methacrylate are added dropwise, wherein acrylic acid, acrylates or methacrylic acid The molar ratio of glycidyl ester to guanidinium salt oligomer is (0.7-1.05):1, the reaction temperature is 80-140°C, and the reaction time is 5-15 h...

Embodiment 1

[0049] Embodiment 1 Preparation of novel cellulose-based guanidine salt antibacterial functional material

[0050] The first step: preparation of guanidinium salt oligomer. Dissolve 11.62g (0.1mol) of hexamethylenediamine in 120ml of isobutanol, adjust the pH to 5-6 with hydrochloric acid; then stand still at -10°C for 12h, filter to leave white crystals, and dry at 60°C for 8h. Obtain 18.3g of hexamethylenediamine hydrochloride, then take 5g of hexamethylenediamine hydrochloride and 1g of dicyandiamide into a 100ml three-necked flask, then add 8.5ml of isopropanol, heat the oil bath to 160°C, stir After 18 hours, an addition reaction was carried out, and 5.5 g of white crystalline guanidinium salt polymer was obtained by cooling.

[0051] The second step: cellulose grafted guanidinium salt.

[0052] a. Weigh 5.5g of white crystalline guanidinium salt polymer, drop into 0.15g of acrylic acid, use the unsaturated double bond in acrylic acid to react with the amino group in gu...

Embodiment 2

[0055] Embodiment 2 Preparation of novel cellulose-based guanidine salt antibacterial functional material

[0056] The first step: preparation of guanidinium salt. Dissolve 11.62g (0.1mol) of hexamethylenediamine in 120ml of isopropanol, adjust the pH to 5-6 with hydrochloric acid; then stand at -10°C for 12h, filter to leave white crystals, and dry at 60°C for 8h. Obtain 18.37g of hexamethylenediamine hydrochloride, then take 8g of hexamethylenediamine hydrochloride and 2g of dicyandiamide into a 100ml three-neck flask, then add 10.5ml of isopropanol, heat the oil bath to 130°C, stir After 18 hours, an addition reaction was carried out, and 9.5 g of white crystalline guanidinium salt polymer was obtained by cooling.

[0057] The second step: cellulose grafted guanidinium salt.

[0058] a. Weigh 9.5g of white crystalline guanidinium salt polymer, drop into 0.25g of acrylic acid, use the unsaturated double bond in acrylic acid to react with the amino group in guanidinium salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com