A rare earth oxide modified tin dioxide varistor material and preparation method thereof

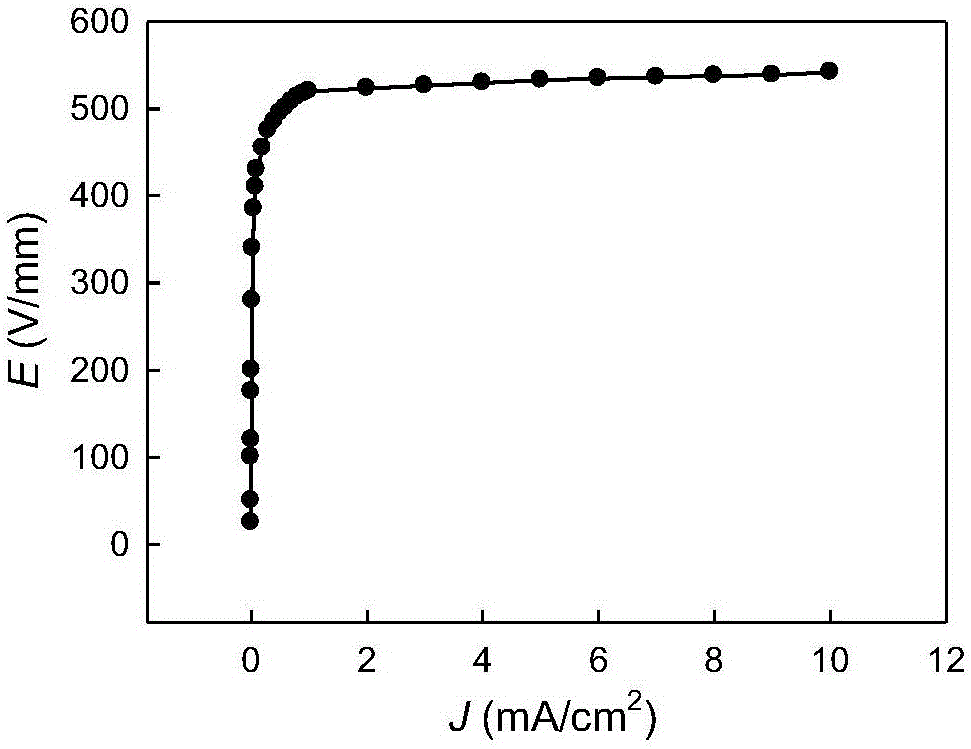

A rare earth oxide, tin dioxide technology, applied in varistor and other directions, can solve the problem of no residual voltage ratio report, can not meet the practical application and other problems, achieve the effect of excellent electrical performance, high potential gradient, low residual voltage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 98.2mol% of SnO by molar ratio 2 , 1.0mol% CoO, 0.05mol% Ta 2 o 5 , 0.05mol% Cr 2 o 3 , 0.35mol% CeO 2 and 0.35mol% Eu 2 o 3 ;

[0022] Mix the weighed mixed powder with zirconia balls and deionized water in a mass ratio of 2:6:3 in a polyurethane ball mill tank, mix and grind on a ball mill, and mill for 12 hours;

[0023] Put the finely mixed slurry into a drying oven, and dry it at 150°C for 5 hours;

[0024] Add a mass fraction of 5% PVA binder to the dried powder, the ratio of powder to polyvinyl alcohol is 20:1, the unit is g / mL, pass through a 100 mesh sieve, and granulate;

[0025] The granulated powder is dry-pressed in a mold, sintered, and the sintering temperature is 1300°C, and the temperature is kept for 3 hours;

[0026] The tin dioxide varistor sintered body is coated with silver to make electrodes, and lead wires are welded on the silver electrodes, and then encapsulated and solidified to make a disc with a diameter of 12mm.

[0027] Aft...

Embodiment 2

[0029] Weigh 97.93mol% of SnO by molar ratio 2 , 1.0mol% CoO, 0.05mol% Ta 2 o 5 , 0.02mol% Cr 2 o 3 , 0.5mol% CeO 2 and 0.5mol% Eu 2 o 3 ;

[0030] Mix the weighed mixed powder with zirconia balls and deionized water in a mass ratio of 2:6:3 in a polyurethane ball mill tank, mix and grind on a ball mill, and mill for 24 hours;

[0031] Put the finely mixed slurry into a drying oven, and dry it at 120°C for 8 hours;

[0032] Add a mass fraction of 5% PVA adhesive to the dried powder, the ratio of powder to polyvinyl alcohol is 20:1, the unit is g / mL, pass through a 60-mesh sieve, and granulate;

[0033]The granulated powder is dry-pressed in a mold, sintered, and the sintering temperature is 1300°C, and the temperature is kept for 3 hours;

[0034] The tin dioxide varistor sintered body is coated with silver to make electrodes, and lead wires are welded on the silver electrodes, and then encapsulated and solidified to make a disc with a diameter of 12mm.

[0035] Afte...

Embodiment 3

[0037] Weigh 97.4mol% of SnO by molar ratio 2 , 1.0mol% CoO, 0.06mol% Ta 2 o 5 , 0.04mol% Cr 2 o 3 , 0.75mol% CeO 2 and 0.75mol% Eu 2 o 3 ;

[0038] Mix the weighed mixed powder with zirconia balls and deionized water in a mass ratio of 2:6:3 in a polyurethane ball mill tank, mix and grind on a ball mill, and mill for 8 hours;

[0039] Put the finely mixed slurry into a drying oven, and dry it at 100°C for 10 hours;

[0040] Add a mass fraction of 5% PVA adhesive to the dried powder, the ratio of the powder to the polyvinyl alcohol solution is 20:1, the unit is g / mL, pass through a 140 mesh sieve, and granulate;

[0041] The granulated powder is dry-pressed in a mold, sintered, and the sintering temperature is 1300°C, and the temperature is kept for 3 hours;

[0042] The tin dioxide varistor sintered body is coated with silver to make electrodes, and lead wires are welded on the silver electrodes, and then encapsulated and solidified to make a disc with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com