Industrialized cultivation method of microbial biomass and system for realizing the method

A technology of microbial biomass and cultivation method, which is applied in the industrialized cultivation of microbial biomass and in the field of microbial cultivation, and can solve problems such as unsuitability for large-scale industrial production, low service life, and unsmooth production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] This example is an example of industrialized cultivation.

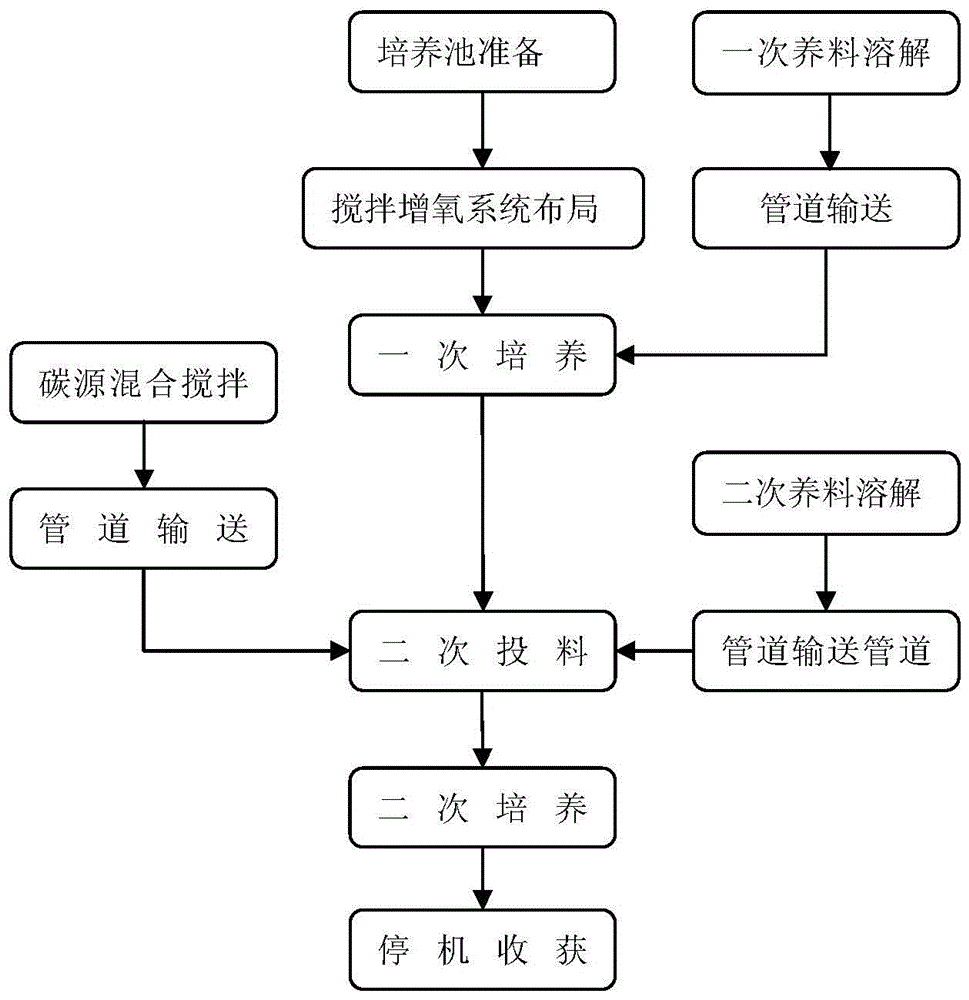

[0174] The production process with a single culture tank as a unit includes: culture tank preparation; stirring and aeration system layout; primary nutrient dissolution; pipeline transportation; primary cultivation; secondary nutrient feeding (including secondary nutrient dissolution and pipeline transportation); carbon source mixing Stirring; mixing of materials; secondary cultivation; shutdown to harvest.

[0175] Prepare the culture tank, determine the type of culture tank, clean and fill.

[0176] Culture tank type:

[0177] Cultivation pool area: 2600-5000 square meters

[0178] Depth of cultivation pool: 1.5-2.0 meters

[0179] Cultivation water volume: 4000-10000 cubic meters

[0180] Requirements for the culture tank: the bottom and wall of the tank are hardened with cement, and the bottom and wall of the culture tank are covered with HDPE film.

[0181] cleaning:

[0182] Cleaning requirements: n...

Embodiment 2

[0269] This example is another example of industrialized cultivation.

[0270] The production process based on a single culture tank includes: culture tank preparation; stirring and aeration system layout; primary nutrient dissolution; pipeline transportation; primary cultivation; secondary nutrient feeding (including secondary nutrient dissolution and pipeline transportation); carbon source mixing Stirring; mixing of materials; secondary cultivation; shutdown to harvest.

[0271] Culture pool preparation, determine the type of culture pool, clean and fill:

[0272] Culture pool type:

[0273] Cultivation pool area: 6000 square meters

[0274] Depth of cultivation pool: 2.0 meters

[0275] Cultivation water volume: 12000 cubic meters

[0276] Requirements for the culture tank: the bottom and wall of the tank are hardened with cement, and the bottom and wall of the culture tank are covered with HDPE film.

[0277] cleaning:

[0278] Cleaning requirements: no chemical poll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com