Method for efficiently producing alpha-oxoglutarate by adopting whole-cell transformation

A technology of whole cell transformation and ketoglutaric acid, which is applied in the field of high-efficiency production of α-ketoglutaric acid by whole cell transformation, can solve the problems of pollution, low yield, high cost of α-ketoglutaric acid, etc. Step-by-step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

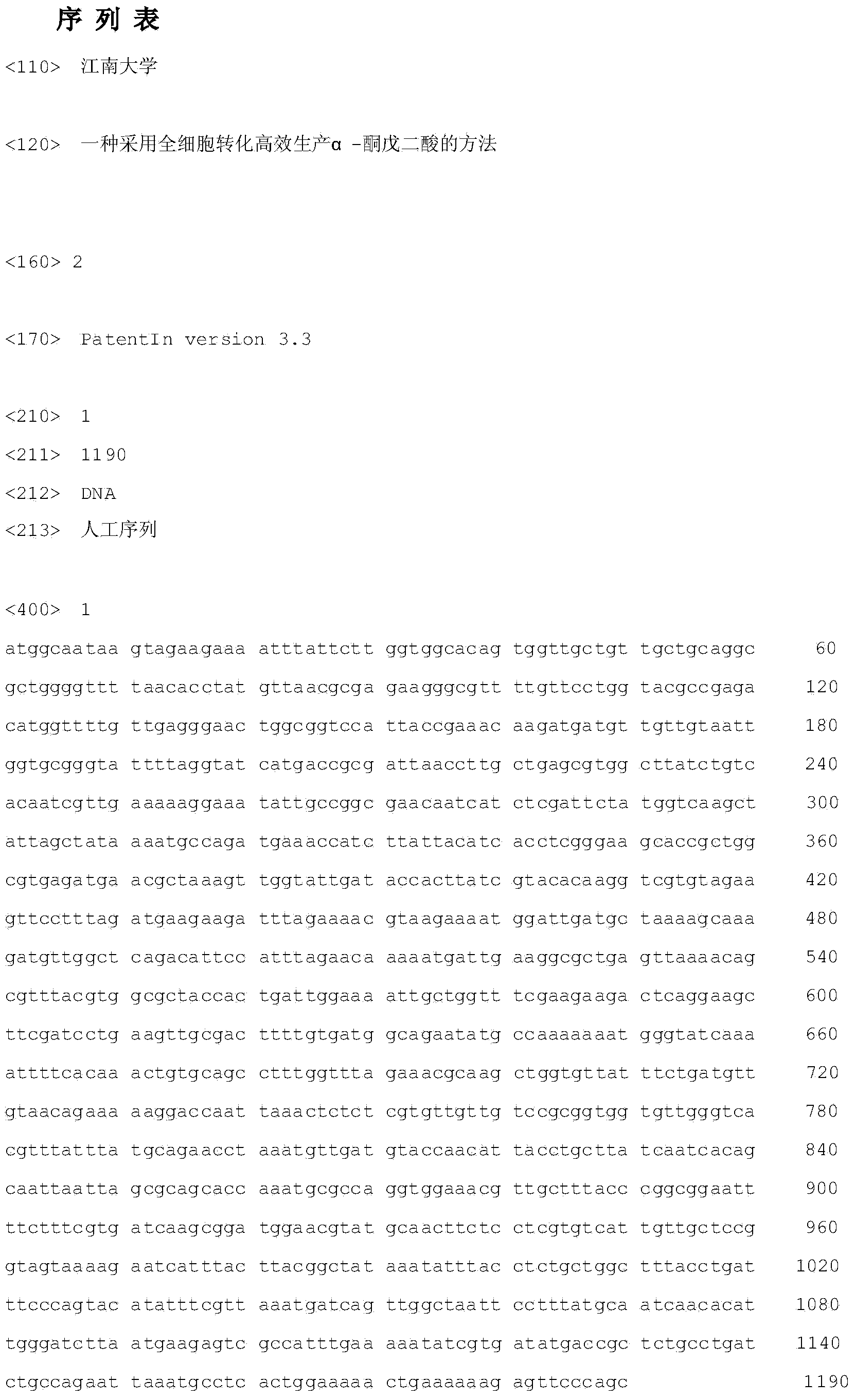

[0022] Example 1 Error-prone PCR transforms L-amino acid deaminase

[0023] Using the constructed recombinant plasmid pET-pm1[1] as a template, Mutazyme II DNA polymerase low-fidelity enzyme amplifies the pm1 gene. After the PCR product was purified and digested, it was ligated with the vector pET-20b(+) to construct a recombinant plasmid, and transformed into Escherichia coli JM109 to construct a mutant library. Pick a single colony grown on the ampicillin-resistant plate and inoculate it into LB, culture it overnight in a 96-well plate with shaking at 37°C, and inoculate it into the TB medium of another 96-well plate, and induce it with IPTG for 5 hours. After screening, plasmids were extracted from strains with high enzyme activity, transformed into B.subtilis168, and whole-cell catalysts were constructed, and the transformation rate was further tested. For the strains with high transformation rate, extract the plasmid and use it as the template for the next round of error...

Embodiment 2

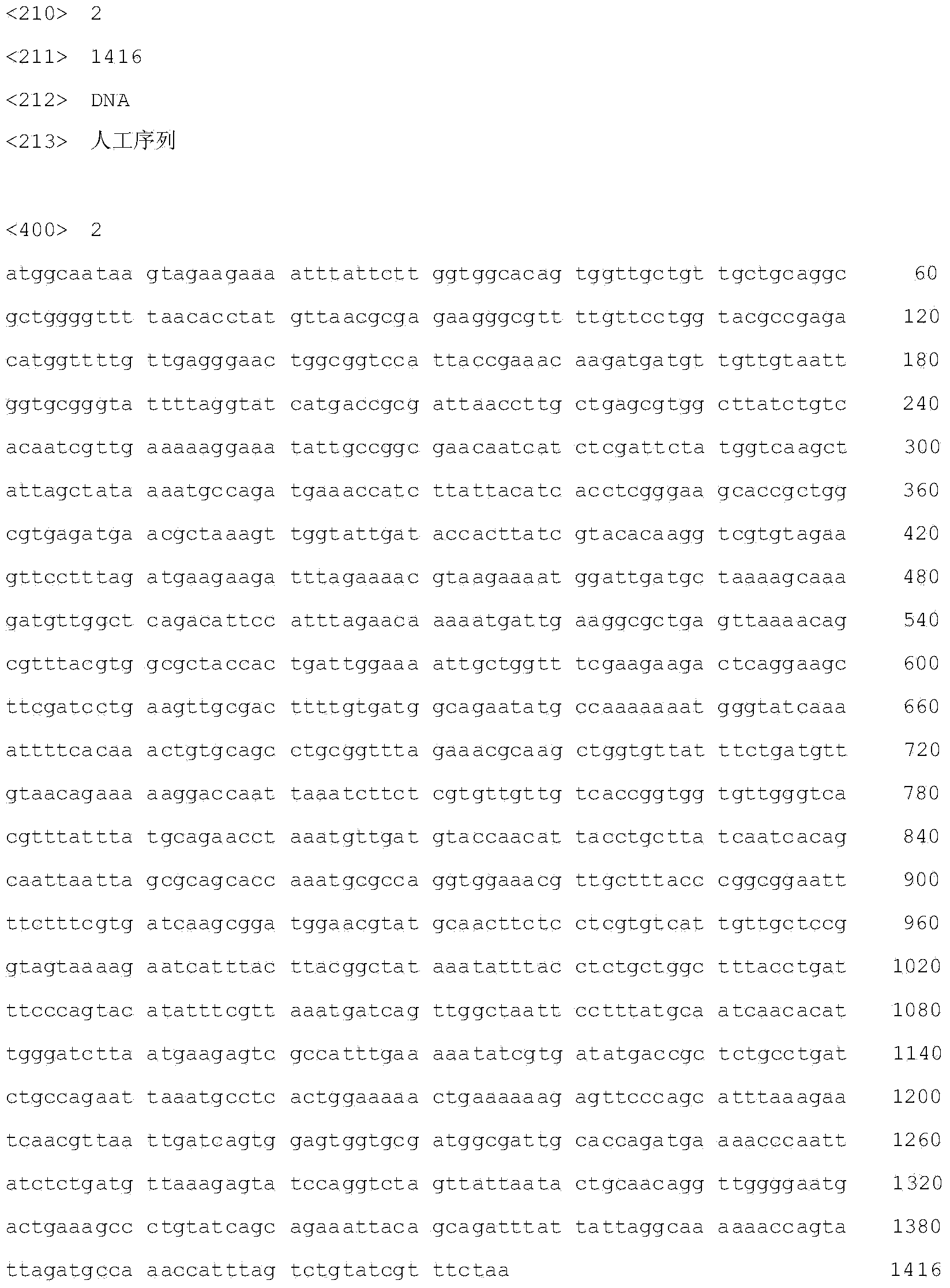

[0026] Example 2 Site-directed mutagenesis transforms L-amino acid deaminase

[0027] The mutation sites obtained in Example 1 were subjected to site-directed saturation mutation one by one, using the constructed recombinant plasmid pET-pm1 as a template, Prime-STAR HS DNA polymerase high-fidelity enzyme and designed mutation primers for one-step amplification, DpnI restriction endonuclease The template DNA was digested with enzymes, then phosphorylated, ligated into a complete plasmid, and transformed into Bacillus subtilis 168. The mutants with the highest yield per locus were: F110I, A255T, E31D, R228C, L249S, I351T. Combine these mutation sites to construct F110I / A255T / E31D / R228C / L249S / I351T.

Embodiment 3

[0028] Embodiment 3 preparation of whole cell catalyst and whole cell transformation process

[0029] The recombinant Bacillus subtilis 168 of Example 1 and Example 2 were inoculated with seed medium (chloramphenicol 10 mg / L), and cultivated overnight at 37°C and 200 rpm. Fermentation was carried out in a 3L NBS fermenter, 1% inoculum was added to 1.8L fermentation medium, the stirring speed, ventilation and temperature were 400rpm, 1.0vvm and 28°C, respectively, when OD 600 When 0.6 was reached, 0.4 mM IPTG was added to induce the expression of L-amino acid deaminase. After 5 hours of induction, centrifuge at 8,000 rpm for 10 minutes at low temperature, collect the bacterial cells, and wash the bacterial cells twice with 20 mM Tris-HCl (pH 8.0) buffer solution. The whole cell transformation system is: L-glutamic acid 15g / L, whole cell catalyst 20.0g / L, the reaction is carried out in 20mM Tris-HCl (pH8.0), 37°C, 200rpm transformation for 24h.

[0030] F110I / A255R / E31D / R228F / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com