A kind of desiliconization agent and its preparation method and application

A technology of desilication agent and extrusion aid, which is used in chemical instruments and methods, refined hydrocarbon oil, catalyst protection, etc., to achieve good economic benefits and application prospects, improve desulfurization, and avoid deactivation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Get 100gNaY molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 5.4, the mesopore volume is 0.03mL / g), added to the 4In the 1000mL aqueous solution of Cl, exchange at 85°C for 1.5 hours. During this process, the pH value is controlled to be 3.5. After the exchange, filter, wash with water, and dry. Treat under the condition of 0.2MPa vapor pressure for 2 hours; then carry out the second ammonium exchange according to the same conditions, after the exchange, filter, wash with water, dry, and then in a 100% water vapor atmosphere, at a temperature of 525 ° C, the water vapor pressure Under the condition of 0.2MPa, treat for 2 hours; the SiO 2 / Al 2 o 3 The molar ratio is 16.4, and the specific surface area is 713m 2 / g, mesopore volume 0.21mL / g, pyridine infrared acid content 0.14mmol / g.

Embodiment 2

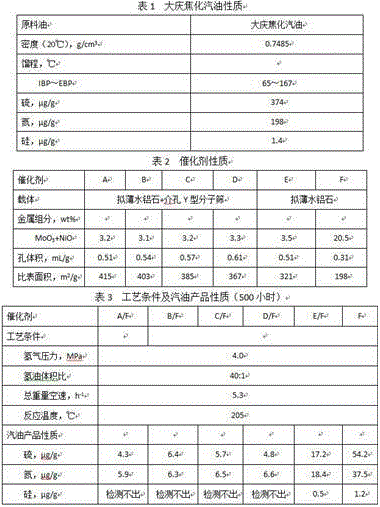

[0039] Get the mesoporous Y-type molecular sieve 25g among the embodiment 1, and 75g pseudo-boehmite (for example, the pseudo-boehmite produced by SASOL company, wherein the monoboehmite content is 70wt%), 2.3g fenugreek powder, mix After uniformity, a mixed solution of 2.6g concentrated nitric acid (96wt%), 1.9g citric acid and 76.5g water was added dropwise, extruded into a clover shape of about 1.5mm, dried at 110°C, and calcined in an air atmosphere at 500°C for 4 hours. Then soak 20g of nickel nitrate and 35g of ammonium heptamolybdate in 100mL of water for 2 hours, and dry in air at 220°C for 4 hours to obtain desiliconization agent A with a specific surface area of 415m 2 / g, pore volume 0.51mL / g. According to the specific requirements, it can be crushed or cut into the required particle size or length, and after vulcanization, it can be combined with the hydrorefining catalyst to carry out the hydrogenation reaction.

Embodiment 3

[0041] Get 20g of mesoporous Y-type molecular sieve in Example 1, and 80g pseudo-boehmite (for example, the pseudo-boehmite produced by SASOL company, wherein the monoboehmite content is 70wt%), 2.3g starch, after mixing , dropwise added a mixed solution of 2.6g concentrated nitric acid (96wt%), 1.9g citric acid and 76.5g water, extruded into a clover shape of about 1.5mm, dried at 110°C, and calcined in an air atmosphere at 500°C for 4 hours. Then soak 20g of nickel nitrate and 35g of ammonium heptamolybdate in 100mL of water for 2 hours, and dry in air at 220°C for 4 hours to obtain desiliconization agent B with a specific surface area of 403m 2 / g, the pore volume is 0.54mL / g. According to the specific requirements, it can be crushed or cut into the required particle size or length, and after vulcanization, it can be combined with the hydrorefining catalyst to carry out the hydrogenation reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com