Method for separation purification of polymyxin B1 from polymyxin B mixed component

A technology of polymyxin and mixed components, which is applied in the field of medicine and can solve the problems of high equipment requirements, poor separation effect, and difficulty in large-scale preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take polymyxin B sulfate sample, add water to dissolve and configure 50mg / ml aqueous solution.

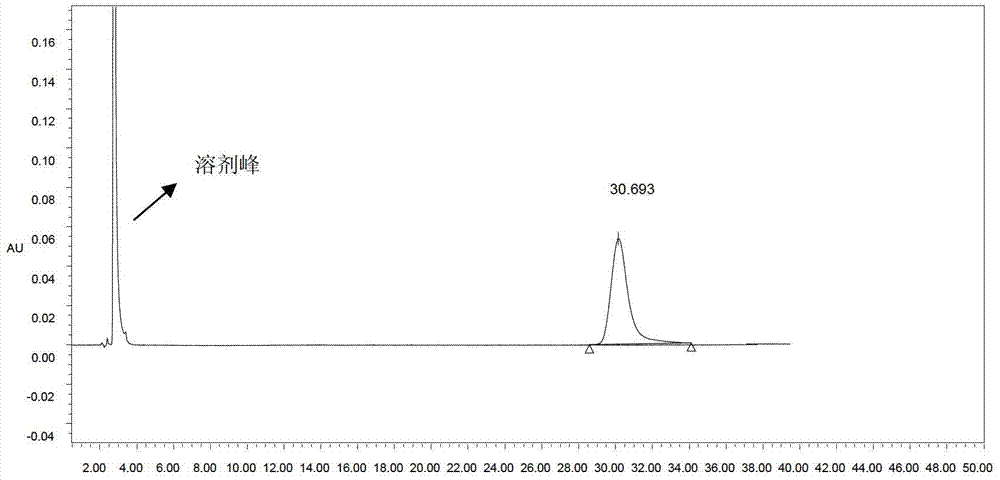

[0031] Pack PS30-300 (Suzhou Nan Microbe Technology Co., Ltd., particle size of 30 μm) chromatography column bed 30ml, after equilibrating 3 times column volume with acidic aqueous solution (formic acid to adjust pH2.3) containing 8% acetonitrile (V / V), Get a 10ml sample and put it on the column, and then elute it with an acidic aqueous solution containing 8% acetonitrile (formic acid adjusts the pH to 2.3). The purity of colistin B1 was 99.2%, and the yield was 63%.

Embodiment 2

[0033] Take polymyxin B sulfate sample, add water to dissolve and configure 10mg / ml aqueous solution.

[0034]Pack 30ml of PS25-300 (Suzhou Nan Microbe Technology Co., Ltd., particle size 25μm) chromatography column bed, equilibrate 3 times column volume with acidic aqueous solution containing 9% acetonitrile (adjust pH 2.0 with formic acid), take 30ml sample and put it on the column , and then eluted with an acidic aqueous solution containing 9% acetonitrile (formic acid to adjust the pH to 2.0). After the eluate was analyzed by HPLC, the part of the polymyxin B1 peak purity greater than 98% was collected, and the obtained polymyxin B1 had a purity of It was 99.5%, and the yield was 60%.

Embodiment 3

[0036] Take polymyxin B sulfate sample, add water to dissolve and configure 100mg / ml aqueous solution.

[0037] Install 30ml of PS30-300 chromatography column bed, equilibrate 3 times column volume with acidic aqueous solution containing 15% ethanol (adjust pH 2.3 with formic acid), take 3ml sample on the column, and then use acidic solution containing 15% ethanol (V / V) Aqueous solution (formic acid adjusted to pH 2.3) was eluted, and after the eluate was analyzed by HPLC, the part of polymyxin B 1 peak purity greater than 98% was collected, and the obtained polymyxin B 1 had a purity of 98.6% and a yield of 45% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com