Separation method of lignocellulose raw material ingredients

A technology of lignocellulose and lignin, applied in the direction of pulping with inorganic alkali, can solve the problem of not realizing the separation of all components, and achieve the effects of less destructive, lower reaction temperature and less corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

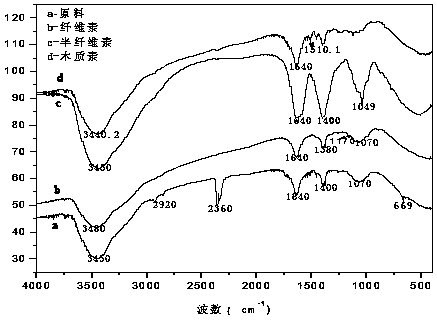

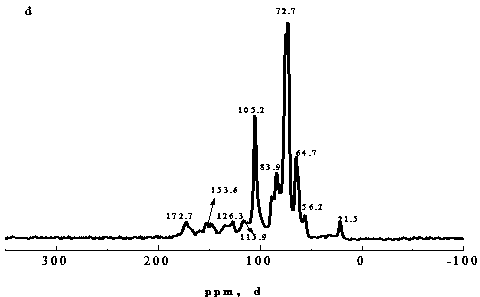

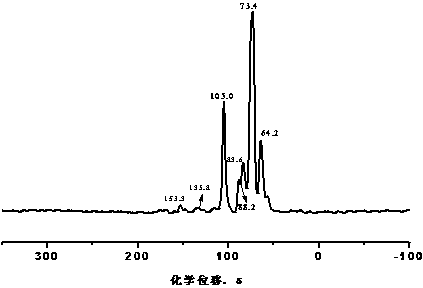

[0020] Embodiment 1: the method for separating components of corn stalks, its steps and conditions are as follows:

[0021] (1) Separation of cellulose: preparation mass concentration is 2% H 2 o 2 solution, adjust the pH to 8 with 0.1M / L NaOH; according to the liquid-solid ratio of 15mL / g, add corn stalks and the solution into the flask, condense, reflux, stir, and react at a temperature of 40°C for 2h. After the reaction is completed, cool to room temperature, vacuum filter and wash the filter cake with distilled water, and dry the filter cake; weigh and calculate the cellulose recovery rate to be 94.3%.

[0022] (2) Separation of lignin: the filtrate of step (1) is adjusted to pH 3~4 with ω=18.3% hydrochloric acid, and flocculent precipitation is arranged, and by centrifugation, precipitation is separated from filtrate, and the solid obtained by separation is lignin The lignin after centrifugation was dried; it was weighed, and the recovery rate of lignin was calculated t...

Embodiment 2

[0025] Embodiment 2: the method for wood chip component separation, its steps and conditions are as follows:

[0026] (1) Separation of cellulose: replace corn stalks with sawdust, and adjust the pH to 10 with 0.1M / L NaOH; the rest are the same as step (1) in Example 1; the calculated cellulose recovery rate is 94.3%.

[0027] (2) Separation of lignin: with the step (2) of embodiment 1; Calculate the recovery rate of lignin to be 27%.

[0028] (3) Separation of hemicellulose: with the step (3) of embodiment 1; Calculate the recovery rate of hemicellulose to be 23.2%.

[0029] (4) The filtrate after alcohol analysis reclaims the ethanol wherein through vacuum distillation, and the remaining filtrate is recycled, and the method of use is the same as that of step (1) to step (3).

Embodiment 3

[0030] Embodiment 3: the method for the component separation of rice husk, its steps and conditions are as follows:

[0031] (1) Separation of cellulose: replace corn stalks with rice husks, and adjust the pH to 11 with 0.1M / L NaOH; the rest are the same as step (1) in Example 1; the calculated cellulose recovery rate is 87.3%.

[0032] (2) Separation of lignin: with the step (2) of embodiment 1; Calculate the recovery rate of lignin to be 53.6%.

[0033] (3) Separation of hemicellulose: with the step (3) of embodiment 1; Calculate the recovery rate of hemicellulose to be 767%.

[0034] (4) The filtrate after alcohol analysis reclaims the ethanol wherein through vacuum distillation, and the remaining filtrate is recycled, and the method of use is the same as that of step (1) to step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com