Bonding method based on multi-field coupling

A bonding and substrate technology, which is applied in the photolithographic process of pattern surface, precision positioning equipment, microstructure technology, etc., can solve the problems of affecting device performance, reducing bonding temperature, and low bonding reliability, etc., and achieves a wide range of applications. Application prospect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

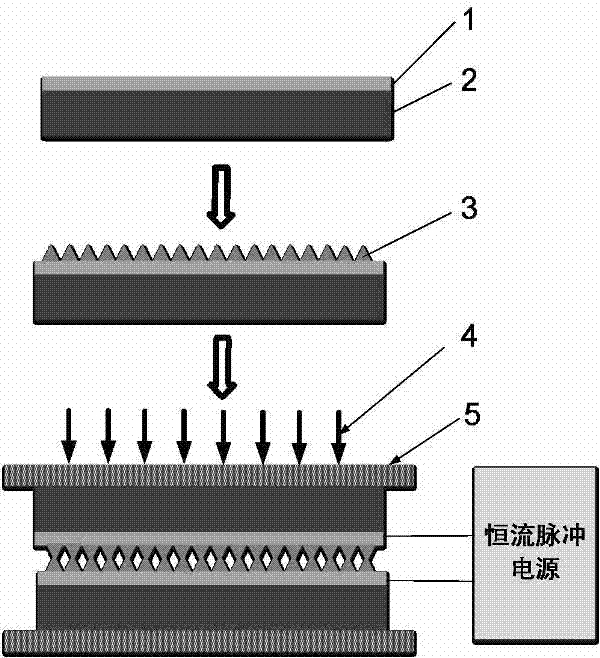

[0013] like figure 1 As shown, the main steps of the specific embodiment of the present invention include:

[0014] (1) The silicon substrate 2 is cleaned by a standard RCA process, and then metallic nickel 1 (Ni) is deposited on the substrate with a thickness of 500 nm by a sputtering process.

[0015] (2) The substrate prepared in (1) was degreased and derusted, and placed in the electroplating solution (copper sulfate pentahydrate 1.5 mol / L, copper nitrate 0.2 mol / L, ethylenediamine 2 mol / L, boric acid 0.3 mol / L, additives SPS15ppm, PEG1000ppm, JGB40ppm, solution temperature 30°C, pH value 5.0), the base material is used as the cathode, the copper plate or insoluble plate is used as the anode, and the base, copper plate and electroplating power supply form a loop through wires. A direct current (2A / dm2) is applied to the substrate by means of an electroplating power supply, and the electroplating time is 180 seconds to form a nano-metal needle-cone structure layer 3 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com