Supercritical hydrothermal synthesis method of nano metal or nano metal oxide particles

An oxide particle, nano metal technology, applied in nanotechnology, metal processing equipment, copper oxide/copper hydroxide, etc., can solve the problems of large particle growth, abnormal particle growth, production pollution, etc., and achieve high purity and dispersibility. Good, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

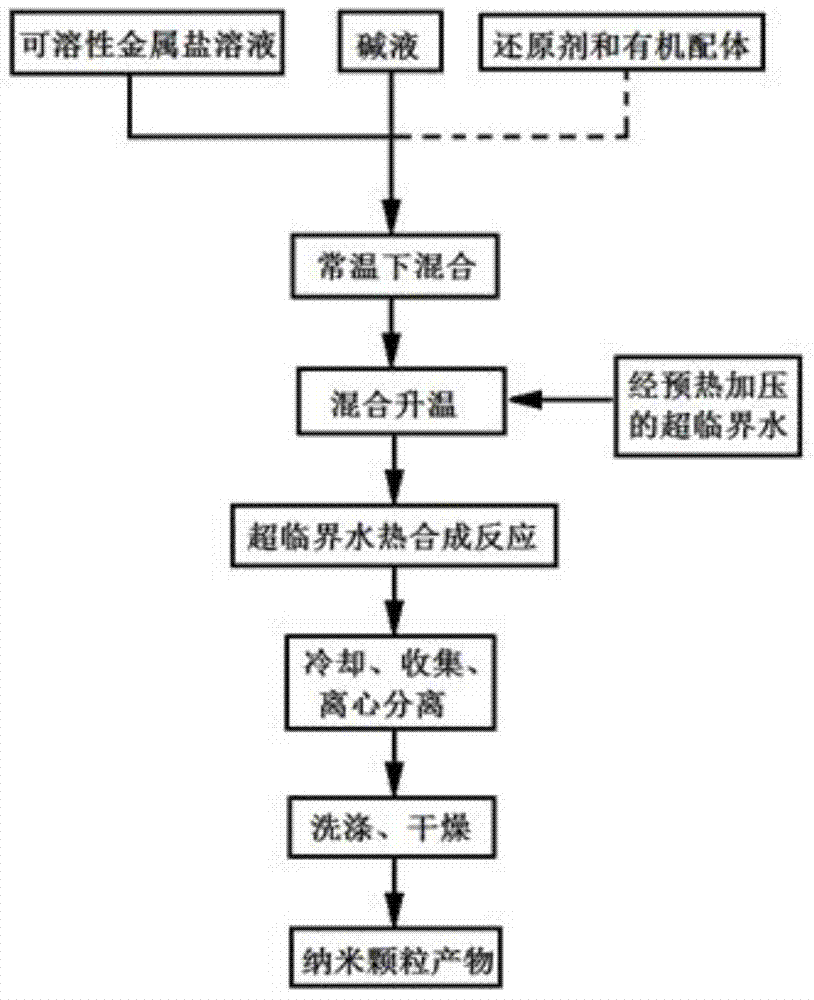

[0028] see figure 1 , the supercritical hydrothermal synthesis method of nanometer metal or nanometer metal oxide particle of the present invention, comprises the steps:

[0029] 1) Use pure water to dissolve the soluble metal salt to obtain a soluble metal salt solution. When preparing the soluble metal salt solution, it can be preheated to increase the solubility of the soluble metal salt.

[0030] 2) pressurize the obtained soluble metal salt solution and lye or the mixture of lye, reducing agent and organic ligand to supercritical pressure, and pre-mix the two at room temperature to obtain a supercritical hydrothermal The reaction precursor of synthetic reaction; Wherein, the addition amount of the mixture of lye or lye, reducing agent and organic ligand should make reaction precursor be neutral, and reducing agent can be hydrogen or formic acid, and it is used for the high valence state Metal ions are reduced, and the molecule of the organic ligand contains a carboxyl gr...

Embodiment 1

[0035] This embodiment takes copper sulfate supercritical hydrothermal synthesis as an example to illustrate the method of the present invention, including the following steps:

[0036] 1) Add CuSO 4 ·5H 2 O crystals (Cu(NO 3 ) 2 Crystal or CuCl 2 Crystals) were dissolved in pure water to obtain a 0.5mol / L copper sulfate (copper nitrate or copper chloride) solution;

[0037] 2) Using NaOH solution to adjust the pH value of the copper sulfate (copper nitrate or copper chloride) solution to be close to neutral, and use the obtained mixture as the reaction precursor of the supercritical hydrothermal synthesis reaction;

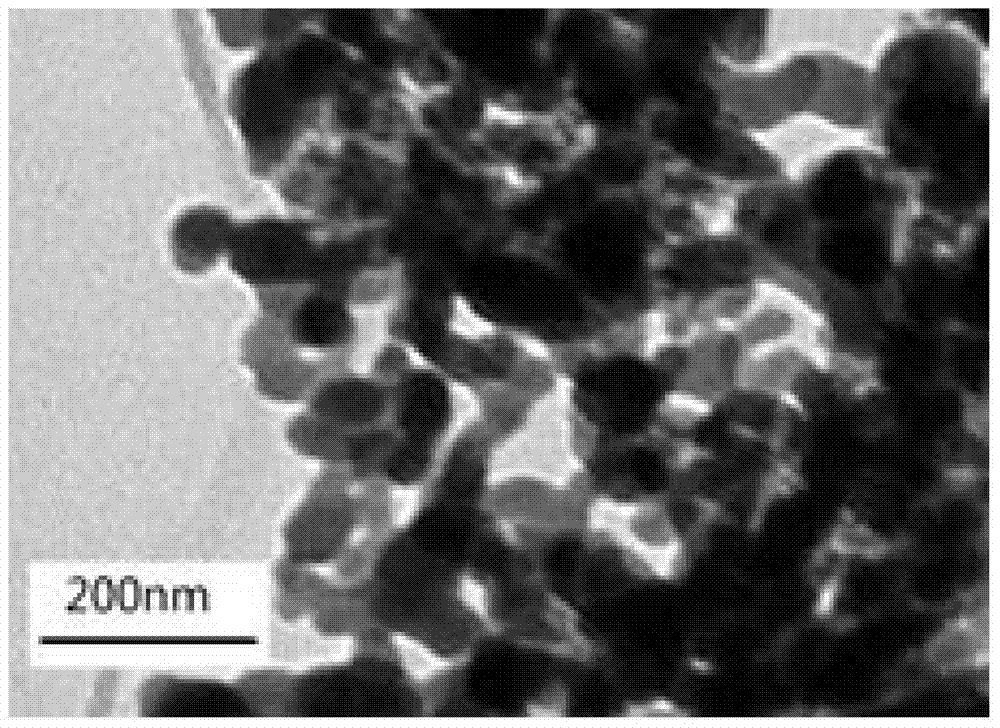

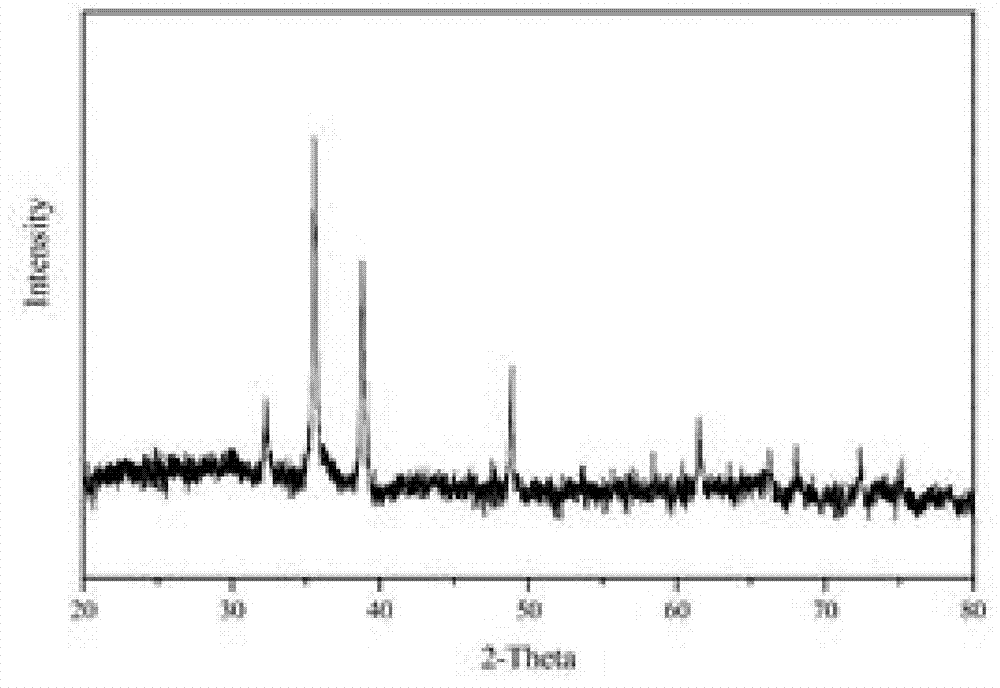

[0038] 3) Use a high-pressure pump to directly mix the reaction precursors generated in step 2) with pure water preheated to supercritical temperature into the supercritical hydrothermal synthesis reactor. After a period of reaction time (usually less than 1min), collect and cool , the reaction product of depressurization, using a centrifuge to separate the ...

Embodiment 2

[0042] In this embodiment, taking the preparation of nano-copper by supercritical hydrothermal synthesis of soluble copper salt as an example, the method of the present invention is described, including the following steps:

[0043] 1) Add CuSO 4 ·5H 2O crystals (Cu(NO 3 ) 2 Crystal or CuCl 2 Crystals) were dissolved in pure water to obtain a 0.5mol / L copper sulfate (copper nitrate or copper chloride) solution;

[0044] 2) Thoroughly mix the obtained copper sulfate (copper nitrate or copper chloride) solution with a mixture of NaOH solution, formic acid solution and ethylenediaminetetraacetic acid as a reaction precursor for supercritical hydrothermal synthesis;

[0045] 3) Use a high-pressure pump to directly mix the reaction precursors generated in step 2) with pure water preheated to supercritical temperature, and then enter the supercritical hydrothermal synthesis reactor. After a period of reaction time, collect the The reaction product of the nano-copper product is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com