Method for preparing porous activated carbon material from rice bran

A technology of porous activated carbon and rice bran, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The rice bran porous activated carbon material prepared by the preparation system of the present invention is an alkaline activator.

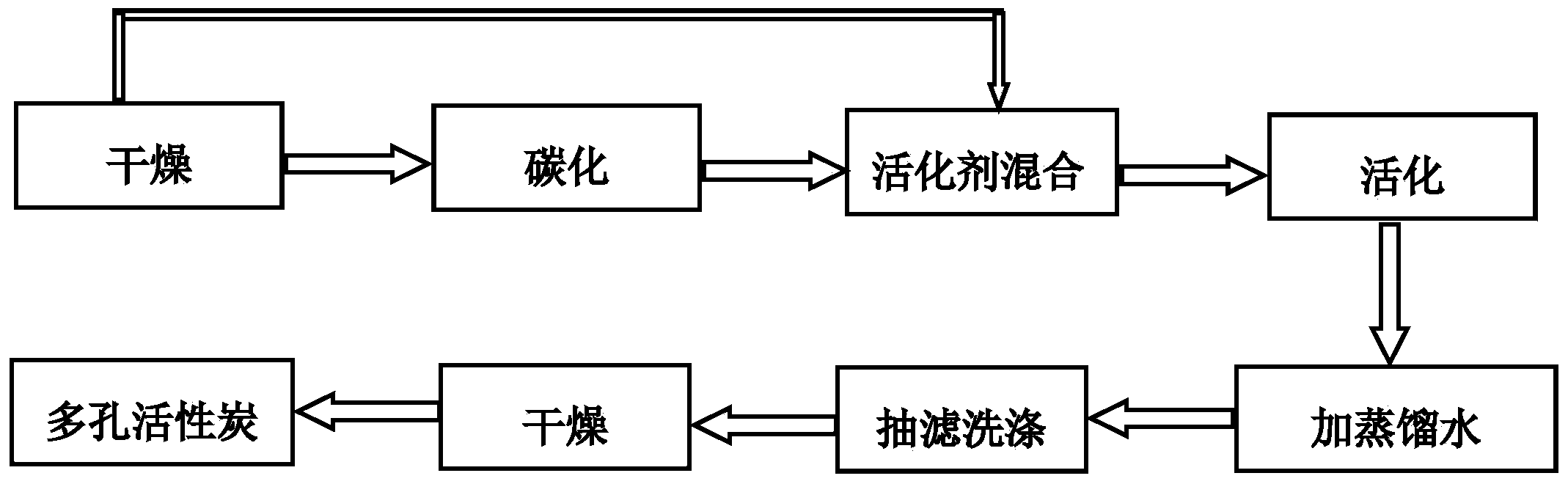

[0029] Step 1: Weigh some rice bran with moisture content less than 14%;

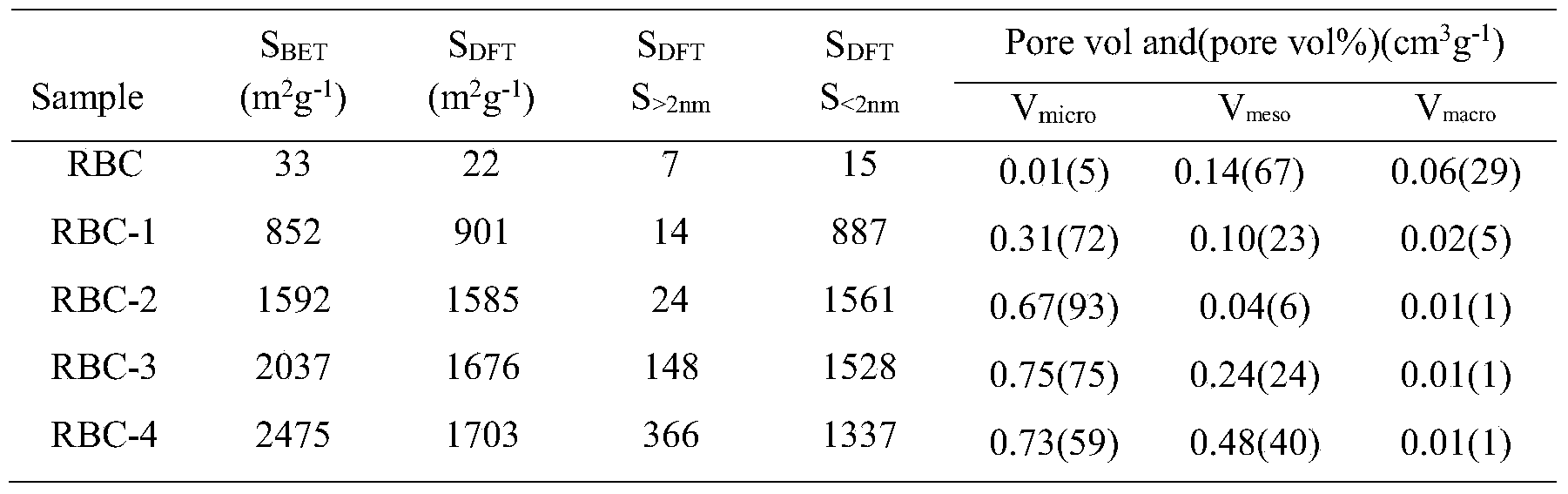

[0030] Step 2: carbonizing the rice bran at 450°C for 60 minutes under the protection of nitrogen gas;

[0031] Step 3: The carbonized rice bran is mixed with an alkaline activator, the mass ratio of alkali to carbon is 4:1, and then activated at 850°C for 160 minutes under the protection of nitrogen gas;

[0032] Step 4: add dilute hydrochloric acid to sonicate, add distilled water to filter and wash until the pH value is 6.5-7, and then dry to prepare porous activated carbon.

Embodiment 2

[0034] The rice bran porous activated carbon material prepared by the preparation system of the present invention is an alkaline activator.

[0035] 1, with the step one of embodiment 1;

[0036] 2, with the step 2 of embodiment 1;

[0037] 3. The carbonized rice bran is mixed with an alkaline activator, the mass ratio of alkali to carbon is 3:1, and then activated at 900°C for 260 minutes under the protection of nitrogen gas;

[0038] 4. Same as Step 4 of Example 1.

Embodiment 3

[0040] The rice bran porous activated carbon material prepared by the preparation system of the present invention is an alkaline activator.

[0041] 1, with the step one of embodiment 1;

[0042] 2, with the step 2 of embodiment 1;

[0043] 3. The carbonized rice bran is mixed with an alkaline activator, the mass ratio of alkali to carbon is 2:1, and then activated at 1100°C for 150 minutes under the protection of nitrogen gas;

[0044] 4. Same as Step 4 of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com