Preparation technology of bacillus licheniformis inoculant capable of resisting strawberry replant

A technology of Bacillus licheniformis and Bacillus licheniformis, which is applied in the directions of chemicals, applications and biocides for biological control, can solve problems such as the destruction of the atmospheric ozone layer, high cost of use, accumulation of toxic substances, etc., to enhance crop resistance. , the effect of increasing yield and reducing morbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

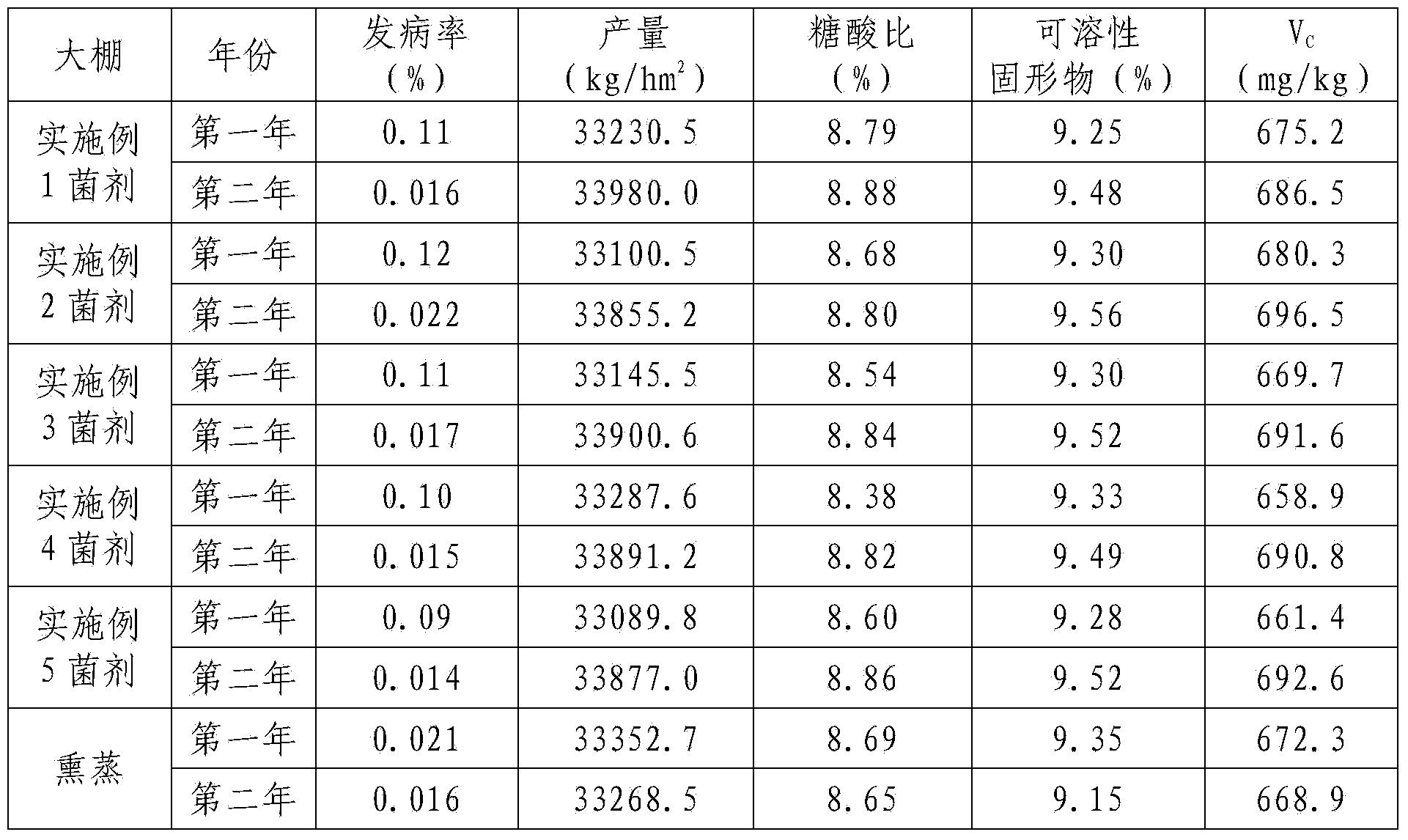

Examples

Embodiment 1

[0048] The production process of Bacillus licheniformis inoculant for preventing strawberry cropping is to inoculate Bacillus licheniformis ACCC01957 in a fermentation medium containing carbon sources, nitrogen sources, inorganic salts and trace elements for aeration and fermentation to produce fermentation broth. The fermentation broth is flocculated, Add protective agent, carrier adsorption, spray drying and spray drying to make bacterial powder; the fermentation medium is composed of the following mass percentage components:

[0049] Soybean meal 2.0%; corn syrup dry powder 0.5%; starch 0.5%; glucose 0.4%; MnSO with a concentration of 30.8mg / L 4 Solution 0.1%; NaCl0.05%; defoamer 0.05‰; pH before elimination=7.6±0.1 pH value after elimination 7.0±0.1;

[0050] The process conditions of aerated fermentation are as follows:

[0051] Stirring speed is 150rpm, 0-4 hours: ventilation volume is 1:0.9vvm, temperature is 32℃-36℃; 4-8 hours: ventilation volume is 1:1.0vvm, temperature is 3...

Embodiment 2

[0063] The production process of Bacillus licheniformis inoculant for preventing strawberry cropping is to inoculate Bacillus licheniformis ACCC01957 in a fermentation medium containing carbon sources, nitrogen sources, inorganic salts and trace elements for aeration and fermentation to produce fermentation broth. The fermentation broth is flocculated, Add protective agent, carrier adsorption, spray drying and spray drying to make bacterial powder; the fermentation medium is composed of the following mass percentage components:

[0064] Soybean meal 3.0%; corn syrup dry powder 1.5%; starch 1.5%; glucose 0.6%; MnSO with a concentration of 30.8mg / L 4 Solution 0.3%; NaCl0.15%; defoamer 0.15‰; pH before elimination=7.6±0.1 pH after elimination=7.0±0.1;

[0065] The process conditions of aerated fermentation are as follows:

[0066] Stirring speed is 250rpm, 0-4 hours: ventilation rate is 1:1.1vvm, temperature is 32℃-36℃; 4-8 hours: ventilation rate is 1:1.2vvm, temperature is 33℃-37℃; af...

Embodiment 3

[0078] The production process of Bacillus licheniformis inoculum for preventing strawberry cropping is to inoculate Bacillus licheniformis ACCC01957 on a fermentation medium containing carbon sources, nitrogen sources, inorganic salts and trace elements to produce a fermentation broth. The fermentation broth is flocculated and added. Protective agent, carrier adsorption, spray drying and spray drying to make bacterial powder; the fermentation medium is composed of the following mass percentage components:

[0079] Soybean meal 2.5%; corn syrup dry powder 0.8%; starch 1%; glucose 0.5%; MnSO with a concentration of 30.8mg / L 4 Solution 0.2%; NaCl 0.1%; Antifoaming agent 0.1‰; pH before elimination=7.6±0.1 pH after elimination=7.0±0.1;

[0080] The process conditions of aerated fermentation are as follows:

[0081] Stirring speed is 150-250rpm, 0-4 hours: ventilation is 1:1vvm, temperature is 32℃-36℃; 4-8 hours: ventilation is 1:1.1vvm, temperature is 33℃-37℃; 8 hours After: ventilation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com