Preparation method of carbon material for adsorbing hydrophilic ionic liquid

An ionic liquid and carbon material technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of small adsorption capacity and low adsorption efficiency, and achieve easy operation, energy saving, huge specific surface area and pore volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

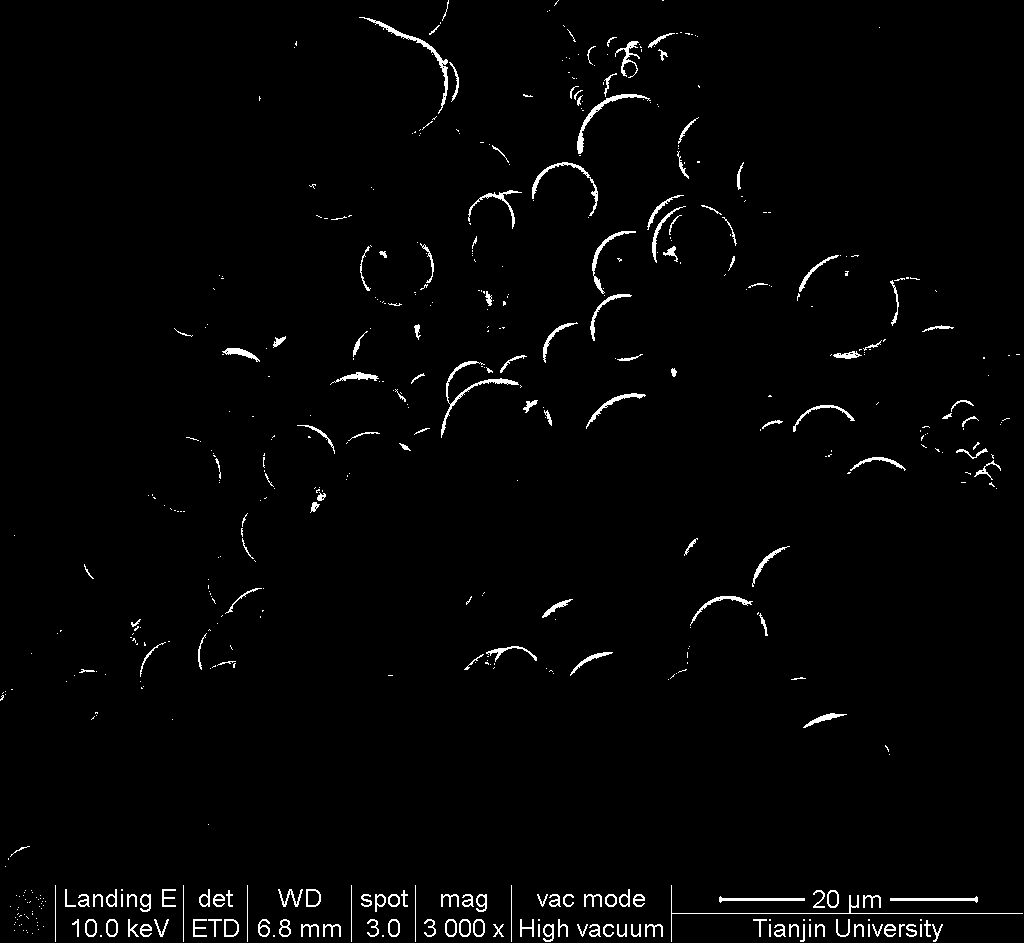

[0020] (1) Add 20 g of microcrystalline cellulose and 60 mL of distilled water successively under magnetic stirring, and continue stirring for 30 minutes;

[0021] (2) Transfer the mixed solution prepared in step (1) into a stainless steel autoclave lined with polytetrafluoroethylene, seal and heat to 250 o C constant temperature for 10 h, stirring at 1000 rpm;

[0022] (3) Cool to room temperature after the reaction, and wash the resulting black powder alternately with distilled water and ethanol, and dry at 80°C for 12 hours to remove all the water, and obtain carbon microspheres with a particle size of 3 to 5 microns;

[0023] (4) After mixing the carbon microsphere material obtained in step (3) and KOH powder at a mass ratio of 1:4, put it into a muffle furnace, pass in nitrogen gas, and set the temperature at 600 °C under a nitrogen atmosphere. o Heat treatment at C for 2 hours;

[0024] (5) The solid obtained in step (4) was alternately washed with 1 mol / L HCl solution...

Embodiment 2

[0029] (1) Add 10 g of microcrystalline cellulose and 60 mL of distilled water successively under magnetic stirring, and continue stirring for 30 minutes;

[0030] (2) Transfer the mixed solution prepared in step (1) into a stainless steel autoclave lined with polytetrafluoroethylene, seal and heat to 260 o C constant temperature for 8 h, stirring at 1000 rpm;

[0031] (3) Cool to room temperature after the reaction, and wash the resulting black powder alternately with distilled water and ethanol, and dry at 80°C for 12 hours to remove all the water, and obtain carbon microspheres with a particle size of 3 to 5 microns;

[0032] (4) After mixing the carbon microsphere material obtained in step (3) and KOH powder at a mass ratio of 1:2, put it into a muffle furnace, pass in nitrogen gas, and in a nitrogen atmosphere at 600 o Heat treatment at C for 4 hours;

[0033] (5) The solid obtained in step (4) was alternately washed with 1 mol / L HCl solution and distilled water until t...

Embodiment 3

[0037] (1) Add 20 g of microcrystalline cellulose and 50 mL of distilled water successively under magnetic stirring, and continue stirring for 30 minutes;

[0038] (2) Transfer the mixed solution prepared in step (1) into a stainless steel autoclave lined with polytetrafluoroethylene, seal and heat to 250 o C constant temperature for 12 h, stirring at 1000 rpm;

[0039] (3) Cool to room temperature after the reaction, and wash the resulting black powder alternately with distilled water and ethanol, and dry at 80°C for 12 hours to remove all the water, and obtain carbon microspheres with a particle size of 3 to 5 microns;

[0040](4) After mixing the carbon microsphere material obtained in step (3) and KOH powder at a mass ratio of 1:4, put it into a muffle furnace, pass in nitrogen gas, and set the temperature at 600 °C under a nitrogen atmosphere. o Heat treatment at C for 2 hours;

[0041] (5) The solid obtained in step (4) was alternately washed with 1 mol / L HCl solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com