Method for improving electrical properties and optical properties of gallium nitride through laser irradiation on gallium nitride epitaxial wafer

A technology of laser irradiation and optical properties, applied in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as electrical and optical properties affecting the crystalline quality of materials, difficulty in epitaxial growth of GaN materials, and slow development of growth technology, etc. Accurate and controllable laser irradiation parameters, improved electro-optical properties, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Cut the gallium nitride epitaxial wafer into square samples with a size of about 1cm×1cm each with a glass knife; immerse in acetone solvent for ultrasonic cleaning for 5 minutes, then rinse; immerse in alcohol solvent for ultrasonic cleaning for 5 minutes, then rinse; immerse in deionized water After ultrasonic cleaning for 6-10 minutes, rinse and dry. Place the pretreated GaN epitaxial wafer on the target stage, and irradiate it with an excimer laser with a wavelength of 248nm in an atmospheric environment; the pulse laser frequency is 3Hz, and the single pulse energy density is 0.5J / cm 2 , the number of pulses is 120. The out-of-focus amount is 4cm, and the compound eye structure is used to shape the outgoing laser light, and the spot area acting on the sample is 1cm 2 , that is, a square spot with a size of 1cm×1cm.

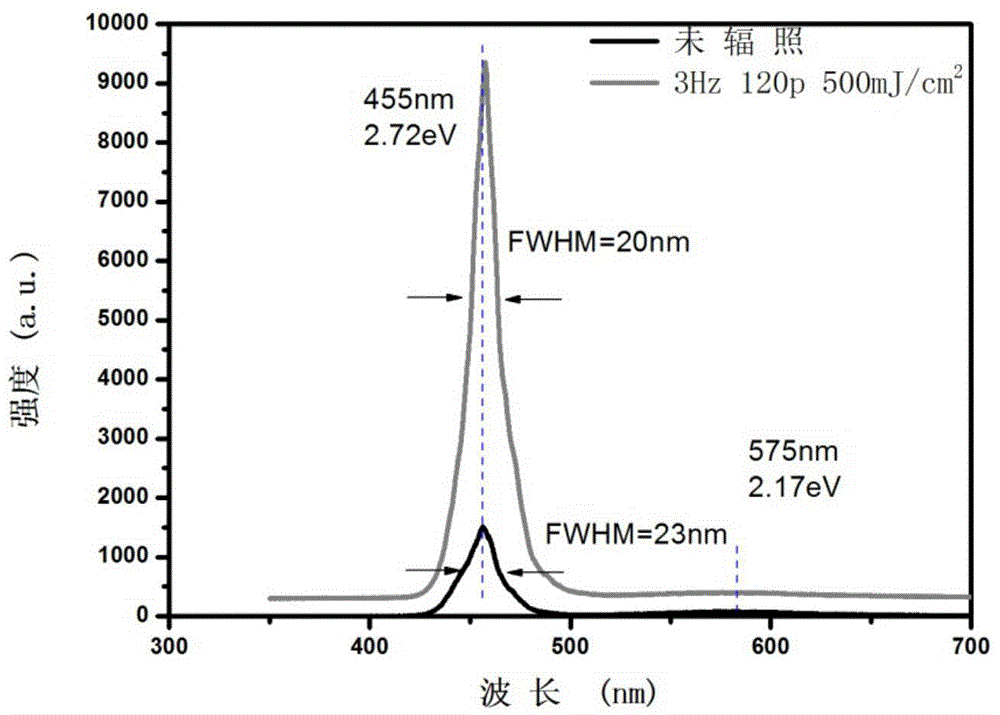

[0026] The photoluminescence spectra of the samples obtained through the above steps were compared with those of the unirradiated samples. The resu...

Embodiment 2

[0028] Cut the gallium nitride epitaxial wafer into square samples with a size of about 1cm×1cm each with a glass knife; immerse in acetone solvent for ultrasonic cleaning for 5 minutes, then rinse; immerse in alcohol solvent for ultrasonic cleaning for 5 minutes, then rinse; immerse in deionized water After ultrasonic cleaning for 6-10 minutes, rinse and dry. Place the pretreated gallium nitride epitaxial wafer on the target stage, and irradiate it with an excimer laser with a wavelength of 248nm in an atmospheric environment; the pulse laser frequency is 3Hz, and the single pulse energy density is 0.5J / cm 2 , the number of pulses is 90. The out-of-focus amount is 4cm, and the compound eye structure is used to shape the outgoing laser light, and the spot area acting on the sample is 1cm 2 , that is, a square spot with a size of 1cm×1cm.

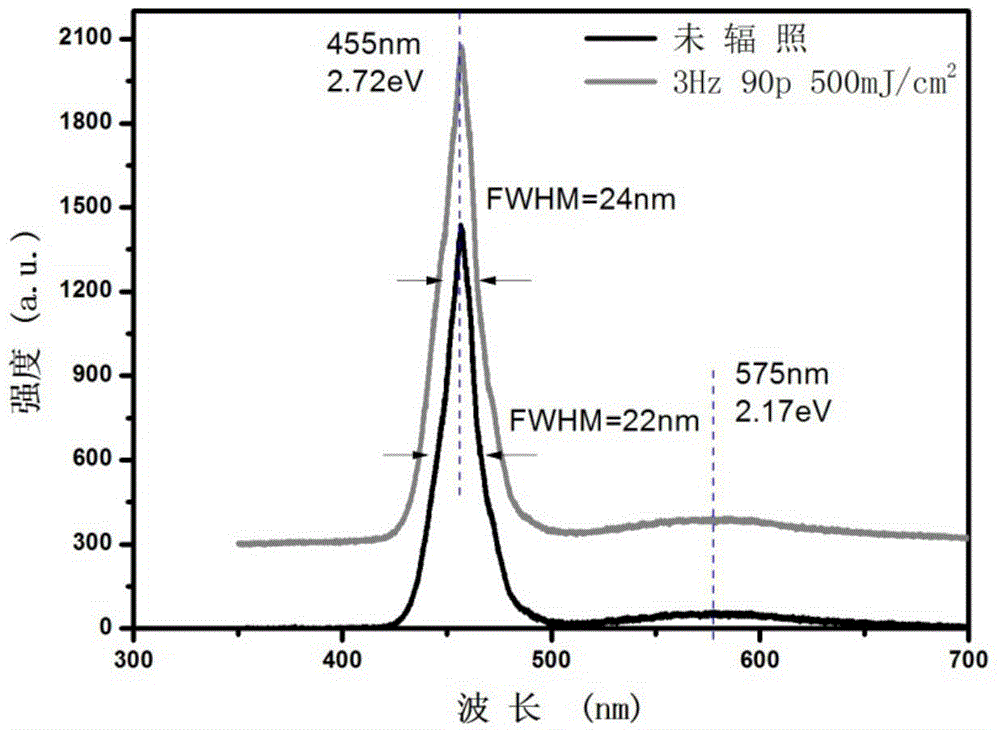

[0029]The photoluminescence spectra of the samples obtained through the above steps were compared with those of the unirradiated samples....

Embodiment 3

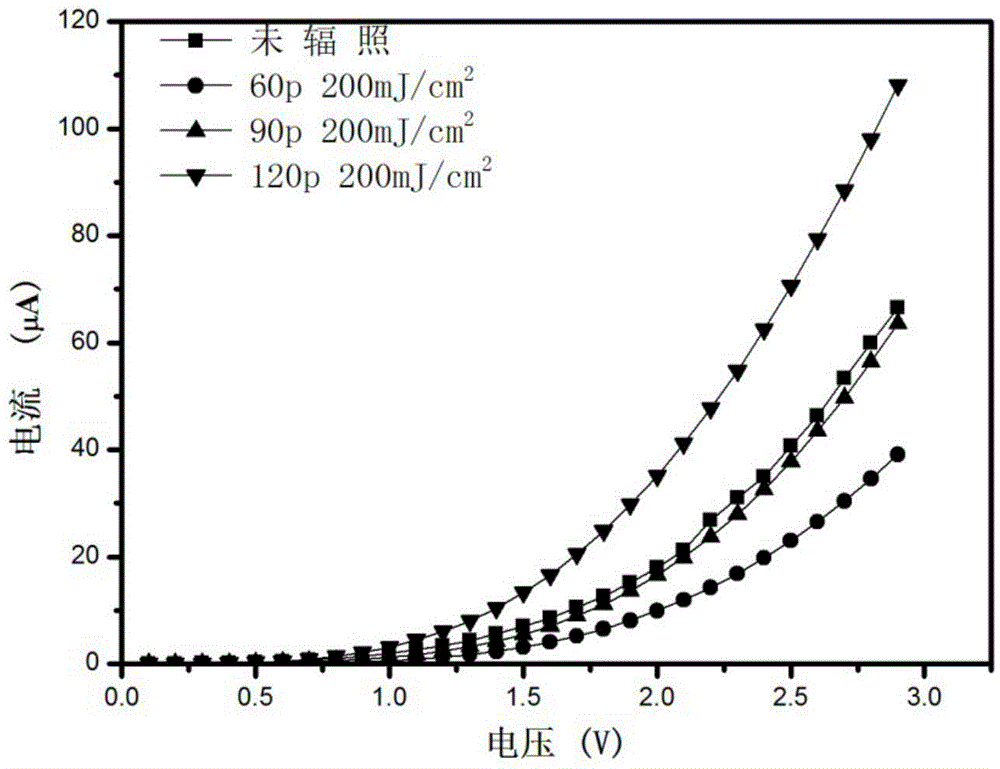

[0031] Cut the gallium nitride epitaxial wafer into square samples with a size of about 1cm×1cm each with a glass knife; immerse in acetone solvent for ultrasonic cleaning for 5 minutes, then rinse; immerse in alcohol solvent for ultrasonic cleaning for 5 minutes, then rinse; immerse in deionized water After ultrasonic cleaning for 6-10 minutes, rinse and dry. Place the pretreated GaN epitaxial wafer on the target stage, and irradiate it with an excimer laser with a wavelength of 248nm in an atmospheric environment; the pulse laser frequency is 3Hz, and the samples are irradiated with different single pulse energies and pulse numbers. Irradiate. At a single pulse energy density of 0.2J / cm 2 In the case of , the samples were irradiated with pulse numbers of 60, 90, and 120, respectively. When the number of pulses is 120, the single pulse energy density is 0.2J / cm 2 , 0.15J / cm 2 The sample is irradiated. The out-of-focus amount is 4cm, and the compound eye structure is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com